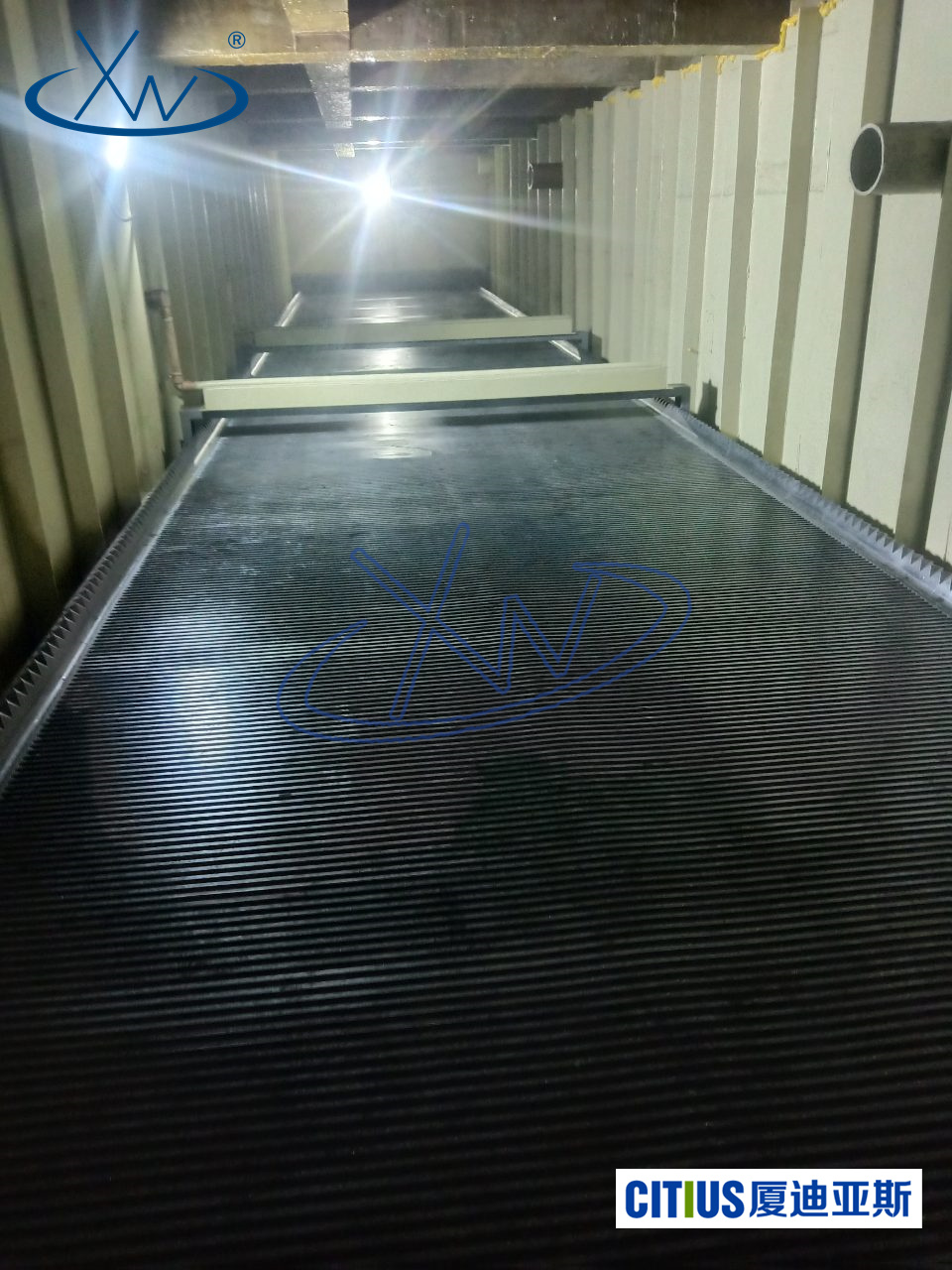

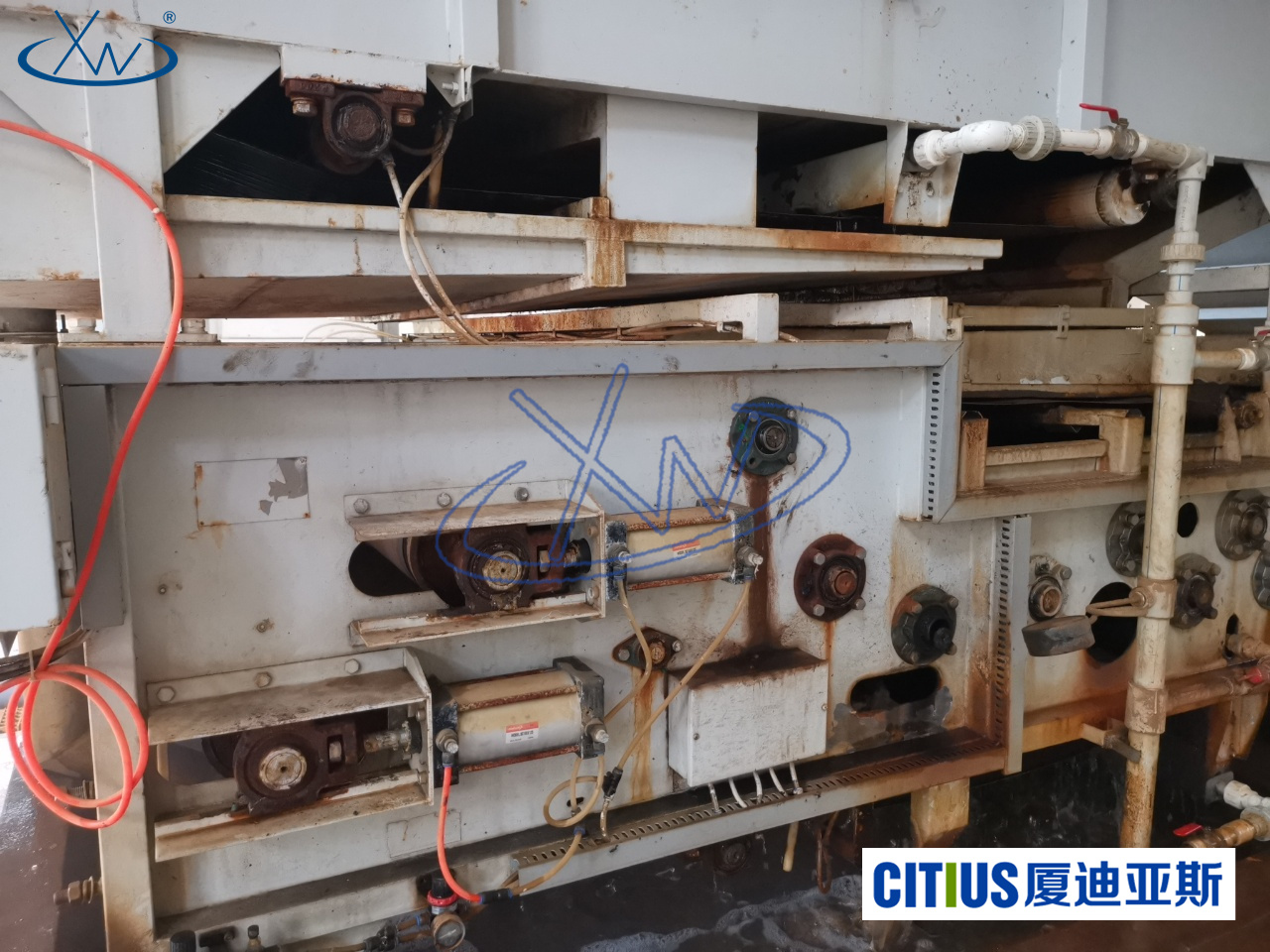

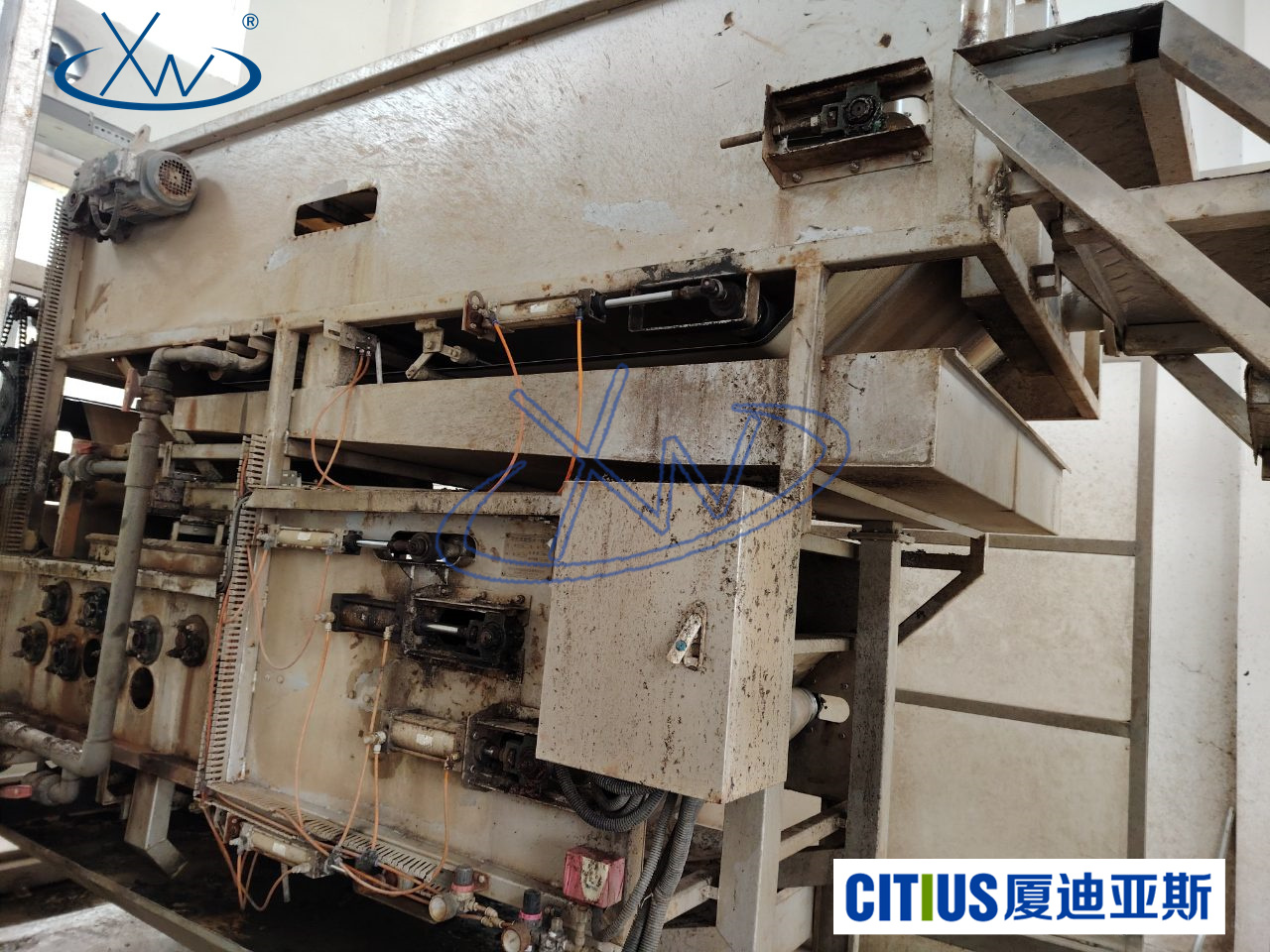

In the chemical raw material processing system, the filtration and dehydration of calcium carbonate and calcium oxide are key factors affecting product quality and production efficiency. With the large-scale application of belt filter presses, higher requirements are put forward for the filter media that match its operating performance. As core filtration elements, industrial filter cloths and industrial filter nets directly determine the process performance of the entire system through their stability, adaptability, and dehydration efficiency.

Details

In the inorganic non-metallic materials processing field, calcium carbonate and calcium oxide are widely used in papermaking, plastics, coatings, rubber, building materials, and other industries. Especially in some production processes, the two need to be processed together to form a mixed slurry with high solid content and strong reactivity. In this process, solid-liquid separation technology is the core link in controlling product quality and operating efficiency. Belt press filter machines, with their continuous operation, large processing capacity, and automatic cake discharge, have become important equipment for dewatering such materials, while the industrial filter cloth used with them is the key to ensuring the stable and efficient operation of the filtration system.

Details

Against the backdrop of "dual carbon" goals and pressure for industrial transformation, the chemical industry is undergoing a profound green revolution. Ensuring efficient and stable processes while achieving near-zero pollutant emissions and resource recycling has become a key focus for many chemical companies. As a core piece of equipment in solid-liquid separation, belt filter presses are widely used in advanced wastewater treatment, crystal mother liquor recovery, chemical softening processes, and Zero Liquid Discharge (ZLD) systems due to their continuous operation, low energy consumption, and low filter cake moisture content. As the "core consumable" of this equipment, the performance of industrial filter cloth directly affects system efficiency and operational economy.

Details

Environmental filter cloth, belt press filter, environmental sewage sludge dewatering

In the systematic engineering of wastewater treatment, filter cloth may be an inconspicuous component, yet it holds immense potential for energy saving and environmental protection. It not only connects sludge and filter cake, equipment and manpower, but also connects a company's commitment and actions towards environmental protection.

In the future construction of green infrastructure in cities, Shadias will continue to provide the environmental protection industry with more "invisible power" through reliable technology, solid products, and attentive service, driving wastewater and sludge treatment towards a more efficient, economical, and sustainable future.

Details

Pulp filtration, a core process in papermaking, directly impacts paper quality and energy consumption through its efficiency and stability. Industrial filter fabrics, an indispensable component of belt press filter machines, necessitate careful selection of suitable brands and structures. Xiamen Xiadias will continue to provide high-performance, customizable filter fabric solutions for the paper industry, assisting enterprises in improving quality, increasing efficiency, and promoting green development.

Details

In the process of dewatering municipal sewage sludge, filter cloth, as a core consumable of belt press filter, its performance directly affects the quality and cost control of sludge treatment. High-performance filter cloth for wastewater treatment plants can effectively improve dewatering efficiency, extend equipment service life, and reduce operation and maintenance costs. Xiamen Citius, with its industry-leading technology accumulation and engineering experience, has become a trusted filtration solution provider for municipal wastewater treatment. In the future, with the continuous improvement of environmental protection standards and higher requirements for the performance and application of filter cloth, Xiamen Citius will continue to be driven by innovation and inject continuous impetus into the sludge treatment industry.

Details

Industrial filter cloth, belt press filter, sewage sludge dewatering

With the continuous increase in the amount of urban sewage treatment, sludge dewatering has become a key link in the operation of sewage treatment plants. Belt filter presses, due to their high efficiency and continuous operation, are widely used in municipal sludge treatment. Industrial filter cloth, as the core filtration medium of this equipment, its performance directly affects the sludge dewatering effect and the stability of the system operation. This article combines the characteristics of domestic sewage sludge to analyze the working principle and process advantages of belt filter presses, focusing on the role and performance requirements of industrial filter cloth, and demonstrates through practical cases the significant effects of high-performance filter cloth in improving the solid content of mud cakes and reducing operating costs. With the increasing demand for efficient and environmentally friendly materials in the industry, industrial filter cloth is developing towards more intelligent and sustainable directions, providing strong support for domestic sewage treatment.

Details

Applications of industrial filter cloth, belt press filter, brewery sludge wastewater treatment

This article introduces the key role of industrial filter cloth in belt press filter machines for treating brewery sludge wastewater, analyzing the characteristics of brewery sludge and the technical requirements and performance advantages of filter cloth in the entire dehydration process. The application of high-performance filter cloth can effectively improve sludge dewatering efficiency, reduce processing costs, and improve operational stability. Xiamen Citius provides customized filter cloth solutions for the brewing industry, helping companies achieve green and sustainable development under the dual pressure of environmental protection and production.

Details

This article focuses on the application of industrial filter cloths and filter belts in the pulp dewatering process of paper mills, with an emphasis on the working principle of belt press filter machines and the core role of filter cloths. The article analyzes common problems faced in pulp pressing, such as low filtration efficiency and severe filter cloth clogging, and highlights the significant value of high-performance filter cloths in improving dewatering efficiency and extending equipment operation cycles. Xiamen Xiadias Filtration Materials Technology Co., Ltd., with its rich experience and professional technology, provides a variety of high-strength, high-permeability, and wear-resistant filter cloth products for the papermaking industry, and has verified its significant effect in optimizing operating costs and improving pulp dryness through practical cases. Finally, the article emphasizes that selecting suitable filter cloths and reliable technical support is the key to achieving green and efficient production in paper mills.

Details

With the glass industry's increasing demand for raw material quality, the optimization of lime powder processing technology has become a key link in improving production efficiency. Belt press filter machines, combined with high-performance industrial filter cloths/meshes, can effectively improve dehydration efficiency and product purity, providing reliable support for the stable production of glass products. Shadias will continue to use professional technical services and innovative material solutions to help the glass industry achieve high-quality development.

Details

Filter cloth for filter press, belt press filter, garnet sludge treatment in mining industry

This article introduces the advantages of belt filter press filter cloth in the treatment of garnet sludge. The sludge generated during garnet processing is characterized by hard particles and high water content, requiring high-efficiency solid-liquid separation equipment. Belt filter presses are widely used in such conditions due to their high processing capacity and stable dehydration effect. As the core filtration medium, the filter cloth's abrasion resistance, permeability, and filter cake release performance are crucial to the treatment effect. Xiamen Xiadias provides customized, high-performance filter cloth solutions based on the characteristics of garnet sludge, and has achieved good application in many garnet companies, helping to achieve efficient dehydration and green production.

Details

Filter cloth for filter press, belt filter press, and livestock bedding.

With increasingly stringent environmental regulations and the growing demand for green development in the livestock industry, filter cloths for filter presses and belt filter presses have undoubtedly become important tools for promoting the treatment and resource utilization of livestock waste. This technological combination enables the livestock industry to not only achieve waste reduction and harmlessness but also promote resource recycling, contributing to the sustainable development of the industry.

Details