Applications of industrial filter cloth and filter mesh - belt press filter - glass industry lime powder processing

Share to

Detailed Description

- Industrial filter cloth and filter mesh applications - belt press filter - lime powder processing in the glass industry

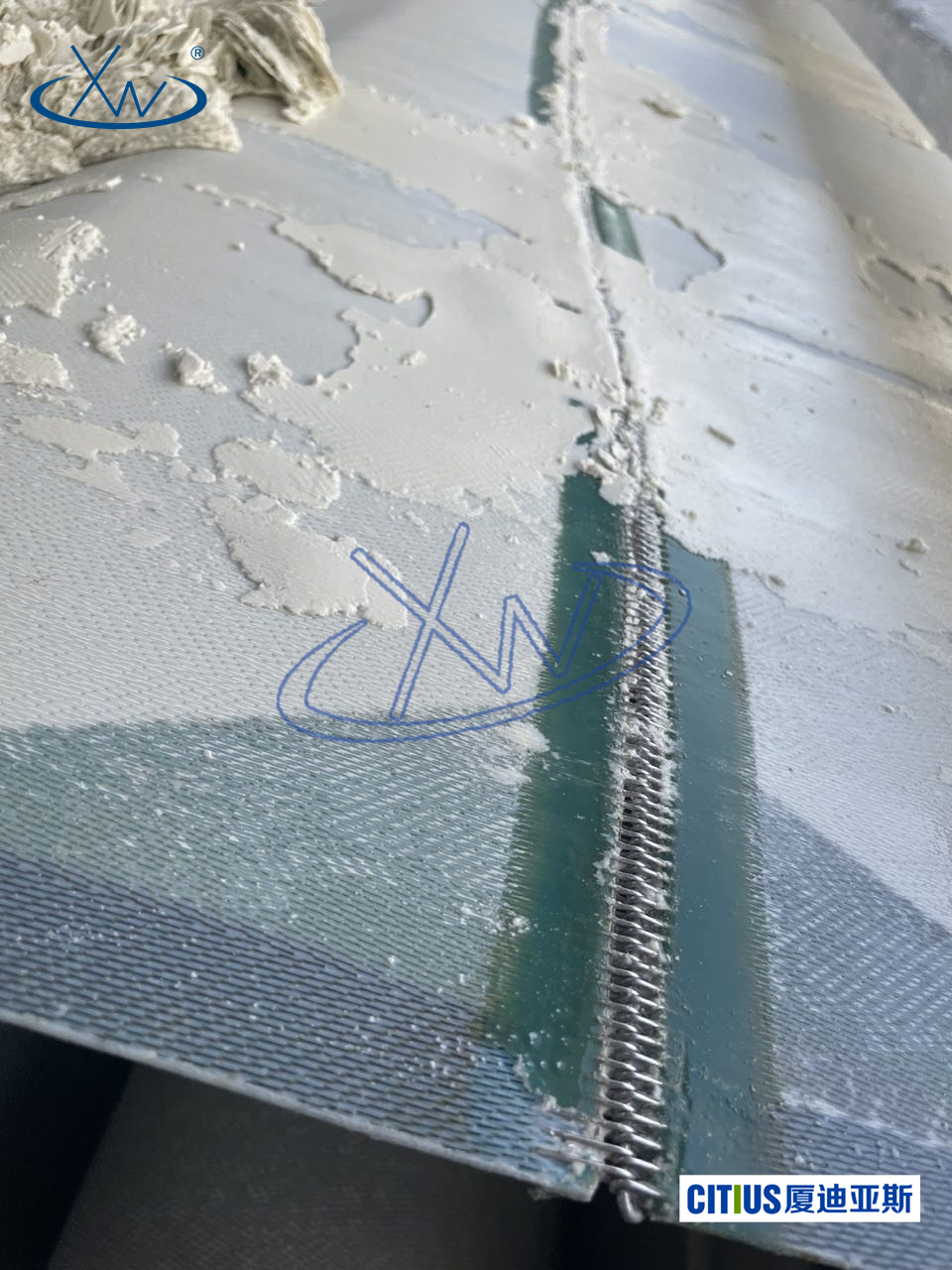

Filter type: Belt press filter

Application industry: Glass industry

Material description: Lime powder

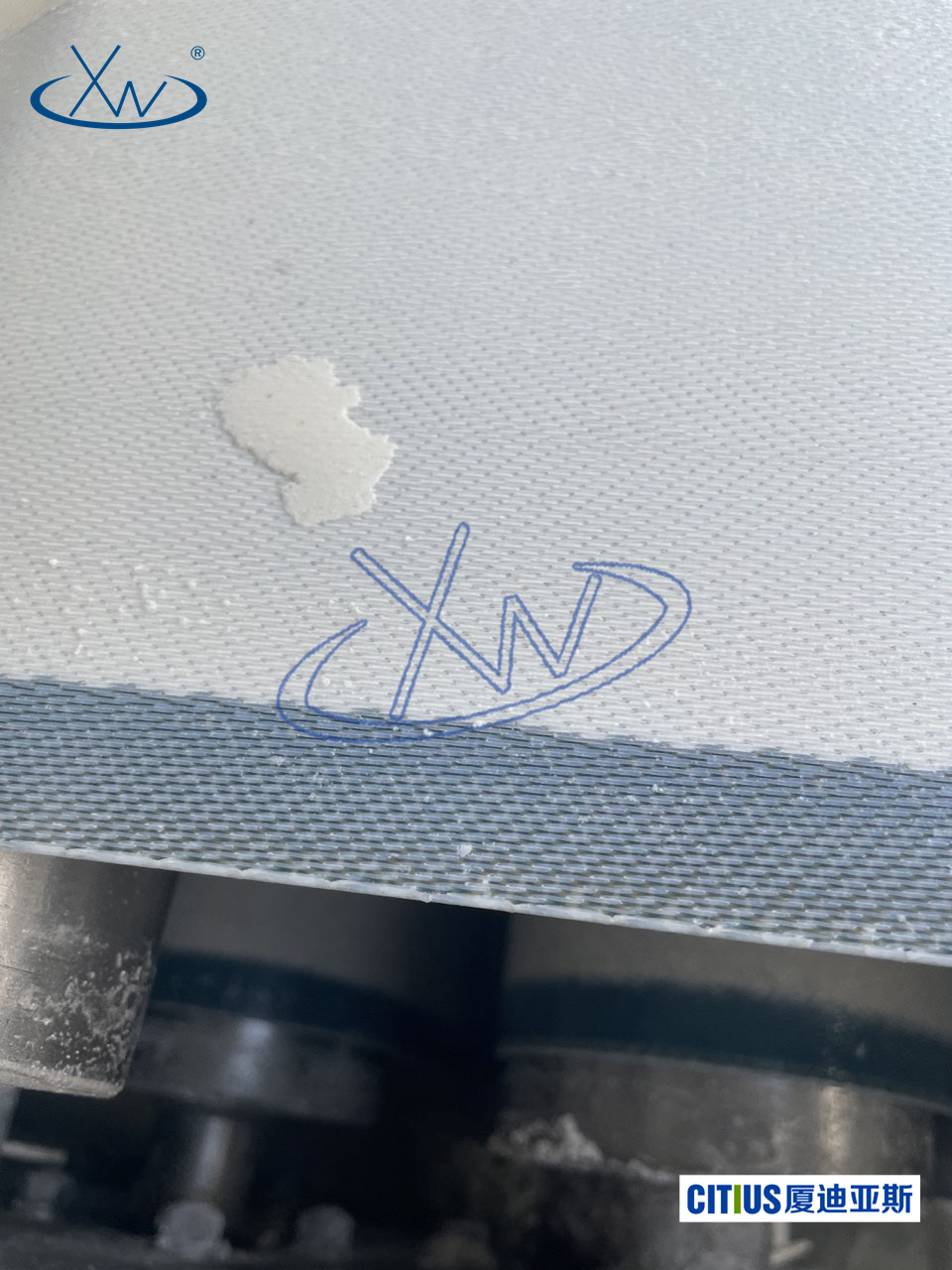

Filter cloth model: 002A

Application of industrial filter cloth and filter mesh in belt press filter for lime powder processing —— A key filtration step in the glass industry

In modern glass manufacturing, lime powder is one of the important flux components, and its quality directly affects the transparency, strength and stability of the finished glass products. In the process of preparing lime powder from limestone, in order to achieve higher purity and particle size control, the lime slurry needs to undergo effective solid-liquid separation treatment. In this process, belt press filter combined with high-performance industrial filter cloth and filter mesh has become a key equipment and material combination to ensure filtration efficiency and product quality.

I. Importance of lime powder in the glass industry

Lime powder is mainly produced by calcining limestone and then wet grinding, the main component is CaO Its main functions in glass manufacturing are as follows:

- Lower the melting point of glass and improve chemical stability;

- Adjust the glass composition, enhance heat resistance and mechanical strength;

- Improve the water resistance and weather resistance of products.

Therefore, the purity and particle size control of lime powder are particularly important, and this relies on an effective dehydration and grading filtration system.

II. Application advantages of belt press filter

As a continuous solid-liquid separation equipment, the belt press filter is particularly suitable for the dehydration treatment of slurries with high water content and high viscosity. It has the following advantages in the wet processing system of lime powder:

- Continuous operation, high degree of automation ;

- Low moisture content of filter cake, easy for subsequent drying and transportation ;

- Small footprint, low energy consumption, strong adaptability ;

- The length and pressure of the pressing section can be adjusted according to the material properties 。

With suitable industrial filter cloth or filter mesh materials, the overall processing capacity and filtration accuracy can be significantly improved.

III. The key role of industrial filter cloth and filter mesh

In the entire belt press system, industrial filter cloth / filter mesh is the core medium that determines the filtration efficiency and filter cake quality . Especially when dealing with lime slurries with high calcium content, fine particle size, and easy scaling, the performance requirements for filter cloth are particularly strict:

1. Strong alkali and wear resistance

Lime powder pH The value is alkaline, and the filter cloth needs to have good chemical stability to prevent alkali corrosion and fiber decomposition.

2. Balance between water permeability and cake release

High-quality filter cloth ensures fast filtration speed while ensuring that the filter cake is easy to fall off after pressing, improving production rhythm and cleanliness.

3. Precise mesh control

High-precision filter mesh can effectively grade lime powder with particle size in tens of microns, improving the fineness stability of the end product.

4. Anti-clogging and self-cleaning ability

To cope with the scaling problem of lime slurry, the filter cloth needs to have a good anti-blocking design. Some high-end models can be combined with a hydrophobic coating or use a smooth single-filament material to improve regenerability.

IV. Xiamen Xiadias's solution

As a professional supplier of industrial filtration systems, Xiamen Xiadias Filtration Materials Technology Co., Ltd. provides a variety of high-performance filter cloth and filter mesh solutions for lime powder processing in the glass industry, which are widely used in belt press filter equipment:

- Provide multi-layer composite filter cloth design according to the viscosity and particle size distribution characteristics of lime slurry;

- Customize mesh accuracy, air permeability and tensile strength according to the specific pressing process requirements of customers;

- All products can provide personalized processing such as edging, punching, and anti-scaling treatment;

- Successfully served many glass raw material processing enterprises and received good reputation and user feedback.

V. Conclusion

With the increasing requirements of the glass industry for raw material quality, the optimization of lime powder processing technology has become a key link in improving production quality and efficiency. Belt press filter combined with high-performance industrial filter cloth / filter mesh can effectively improve dehydration efficiency and product purity, providing reliable support for the stable production of glass products. Xiadias will continue to use professional technical services and innovative material solutions to help the glass industry achieve high-quality development.