In the core area of the wastewater treatment plant, sewage sludge is slowly being squeezed from a turbid and thick state into a mud cake with low water content, easy to transport and handle. This transformation is achieved by the belt press filtration system, and the industrial filter cloth is the core force of this "dewatering battle".

As a leading brand in the field of industrial filtration materials, Xiamen Xiadias Filtration Materials Technology Co., Ltd. has over 30 years of experience, focusing on serving municipal wastewater and environmental protection industries, and providing high-performance industrial filter cloths for various belt press filtration machines.

Details

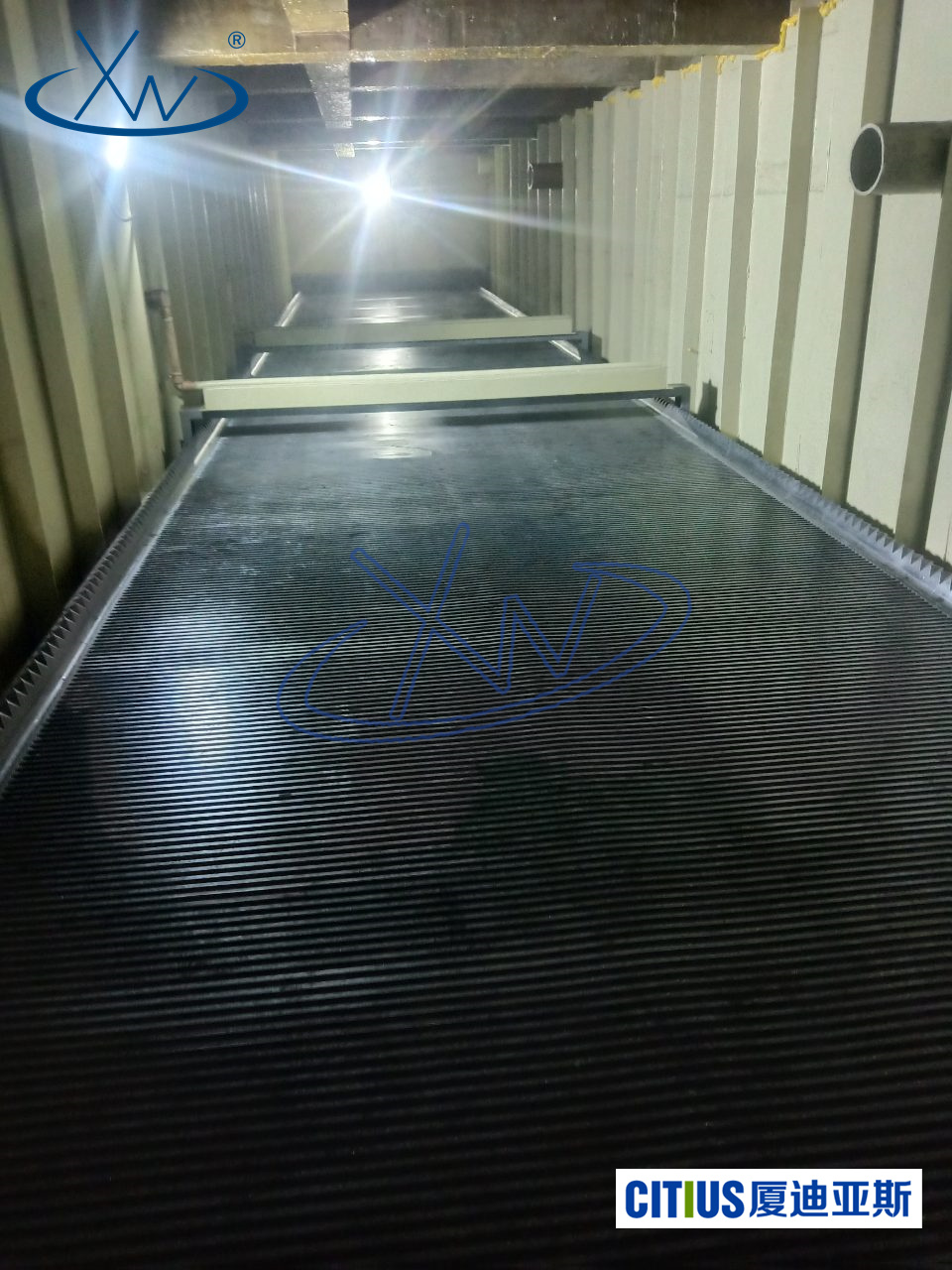

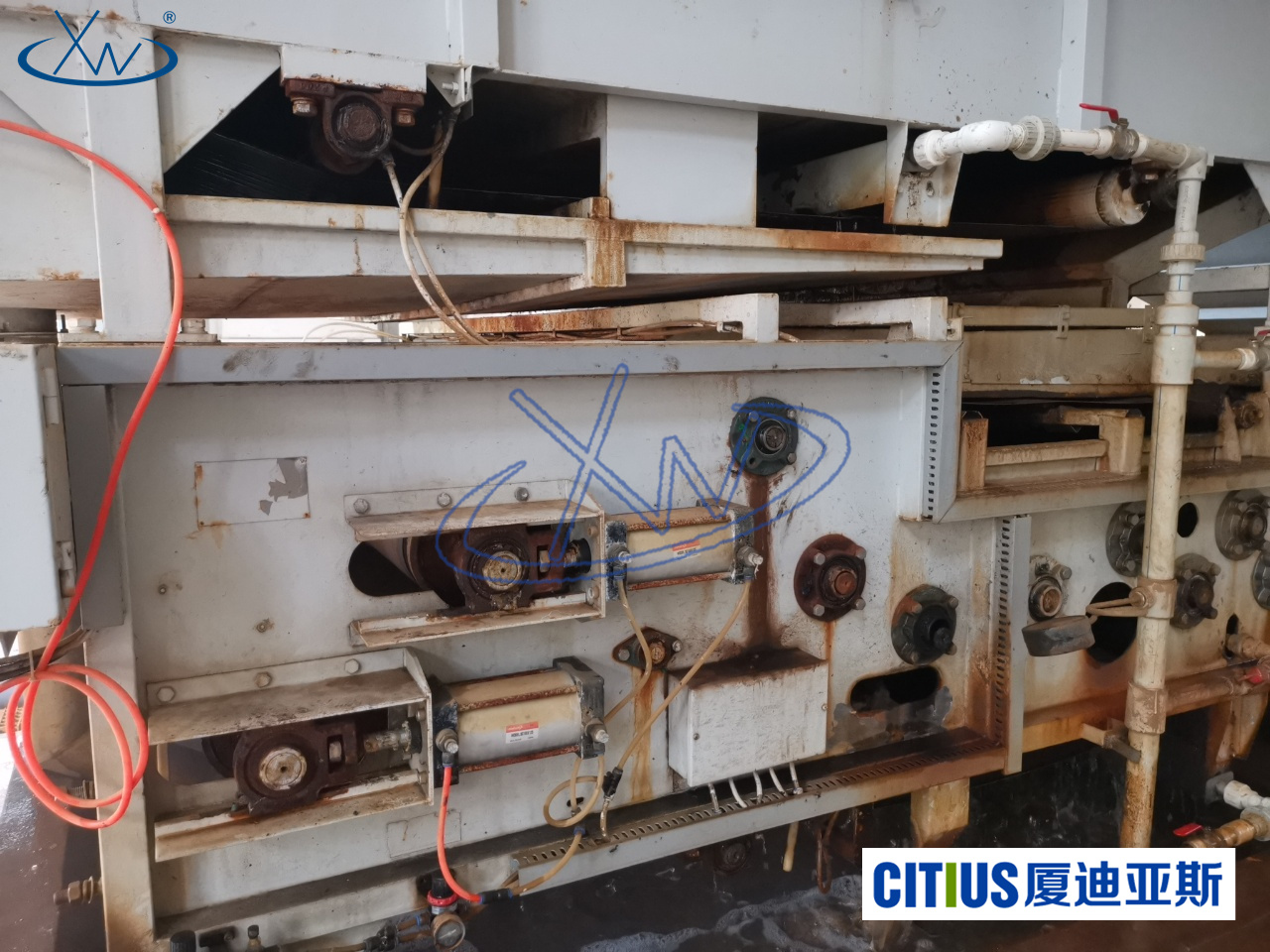

In urban wastewater treatment systems, sludge reduction and dewatering are crucial processes. Belt filter presses have become the mainstream equipment for sludge dewatering in municipal wastewater treatment plants due to their high processing capacity, continuous operation, low energy consumption, and high degree of automation. One of its core components—the industrial filter cloth—directly affects sludge dewatering efficiency, operational efficiency, and equipment lifespan.

Details

Belt press filter cloth application - industrial wastewater treatment in sewage plants

Efficient treatment of industrial wastewater is not only an environmental requirement, but also the cornerstone of a company's green development. In the entire solid-liquid separation process, the filter cloth of the belt press filter plays a bridging role between the equipment and the process as a key medium. It not only determines the moisture content of the mud cake and the quality of the filtrate, but also affects the equipment operation cycle and cost control.

Xiamen Xiadias, with years of technological accumulation and material innovation, is willing to provide safer, more professional, and more sustainable industrial filter cloth solutions for the national wastewater treatment industry, and work together with you to protect the future of the water environment.

Details

Dewatering chemical sludge is not a simple physical process, but a systematic project involving multiple complex chemical, mechanical, and material properties. Industrial filter cloth, as the most crucial "working medium" in belt press filter machines, not only affects the dewatering effect but also the equipment operation efficiency and enterprise environmental compliance.

Choosing Xiamen Dias is choosing a long-term partner with deep industry experience, rich technical accumulation, and quick service response. We are willing to work hand in hand with chemical enterprises to achieve more stable, efficient, and environmentally friendly chemical sludge dewatering with high-performance filter cloth.

Details

Industrial filter cloth, filter mesh usage - belt filter press - urban sludge treatment wastewater

Sludge Dewatering: The "Last Mile" of Urban Wastewater Treatment

With the acceleration of urbanization, the capacity of municipal wastewater treatment has been continuously enhanced, but the resulting sludge production has also increased dramatically.

Sludge contains a large amount of water, organic matter, heavy metals, and pathogenic microorganisms. Without proper treatment, it is very likely to cause secondary pollution.

Therefore, efficient dewatering and stable volume reduction have become an important part of wastewater plant operation.

Among the numerous sludge dewatering equipment, belt filter presses, due to their high processing capacity, low energy consumption, continuous operation, and low operating costs, are widely used in municipal sludge treatment projects.

In this equipment, industrial filter cloth and filter mesh, as the core separation medium, directly determine the dewatering efficiency, filter cake solid content, filtrate quality, and even the stability and operating cost of the entire system.

Details

With the continuous expansion of the ceramic industry, the issue of wastewater and sludge discharge during ceramic production has received increasing attention. In particular, the processes of ceramic body forming, polishing, and grinding generate large amounts of highly viscous sludge with high solid content. To achieve environmentally compliant discharge and resource utilization, belt press filter presses have become one of the key pieces of equipment for ceramic sludge treatment, and **industrial filter cloth (filter mesh)** plays an irreplaceable core role in this process.

Details

Vegetable dehydration, while seemingly simple, actually involves the synergistic wisdom of process efficiency, materials science, and equipment matching. For thirty years, Xiamen Xiadias has focused on filtration, providing reliable industrial filter cloth support to global food companies. Whether it's providing a mesh belt for a vegetable pre-processing line or developing a customized solution for an overseas food processing group, Xiadias always adheres to the core principles of "professionalism, efficiency, and safety" to create tangible value for customers.

From farm to table, filtration is everywhere. Xiadias is always there.

Details

Industrial filter cloth, filter mesh applications; belt press filter; xylitol industry; corn cob

In the xylitol production process, corncob is used as the main raw material and needs to go through multiple steps such as pretreatment, hydrolysis, solid-liquid separation, purification, and crystallization. Among them, the solid-liquid separation process is crucial for improving the purity of the sugar solution, reducing energy consumption, and optimizing subsequent processes. Belt press filter combined with high-performance industrial filter cloth and filter mesh has become a key equipment configuration in this process.

Details

Industrial filter cloth usage - belt press filter cloth - juice factory, apple juice pressing

In the juice production process, especially in apple juice processing, belt press filter presses are widely used due to their continuous, efficient, and low energy consumption characteristics. Industrial filter cloth, as the core filtration medium in the pressing system, directly affects the juicing efficiency, juice clarity, and the stability of equipment operation.

Details

In the modern bio-fermentation and food additive manufacturing fields, citric acid is a fundamental organic acid widely used in the food, pharmaceutical, and chemical industries. Its production process has long since achieved a development trend that balances high efficiency and green practices. The fermentation process using corn stover as a raw material is particularly typical, and the dehydration treatment of corn stover is a key step affecting the energy efficiency and environmental indicators of the production line.

In this process, belt press filter machines are widely used due to their continuous operation, strong adaptability, and high dehydration rate. However, the core consumable that truly determines its processing effect—industrial filter cloth—is the key to the stable operation of the system and the control of filter cake quality.

Details

With increasing emphasis on the recycling and environmentally friendly processing of biomass resources, the treatment of okara, a typical byproduct of bean product processing, is no longer limited to simple composting or landfilling. To achieve efficient dehydration and resource utilization, more and more companies are adopting belt press filters, with high-performance industrial filter cloths and meshes being key components of this process.

Details

With increasingly stringent environmental regulations, wastewater treatment in the liquor manufacturing process has become an important part of green production. Liquor wastewater contains a large amount of organic matter, suspended solids, yeast residue, and residual sugar. If not effectively treated, it will not only pollute the environment but also increase the operational risks of enterprises. Belt press filter, as a highly efficient sludge dewatering equipment, has been widely used in the wastewater treatment process of alcohol, spirits, and wine industries. The performance of its core components—industrial filter cloth and industrial filter mesh—directly affects the operating efficiency and treatment effect of the entire system.

Details