Industrial filter cloths and filter screens are not only important components of belt filter presses, but also key factors determining the success or failure of garment wastewater treatment. Scientific and reasonable selection and configuration of filter cloths can significantly improve filtration efficiency, reduce treatment costs, and increase the rate of environmental compliance. In the future, with the upgrading of environmental protection technologies and stricter policy regulations in the garment industry, innovation in filter cloth materials and systems will continue to provide strong support for the industry's green and sustainable development.

Details

With the papermaking industry's increasing demands for environmental standards and production efficiency, pulp dewatering technology, as a core process in pulp and papermaking, is receiving more and more attention. In this process, belt filter presses and their associated industrial filter cloths and filter meshes are gradually becoming key technical equipment combinations for efficient pulp dewatering and wastewater reduction. This article will focus on paper pulp dewatering technology and delve into the application value, selection principles, and performance in practical engineering of industrial filter cloths.

Details

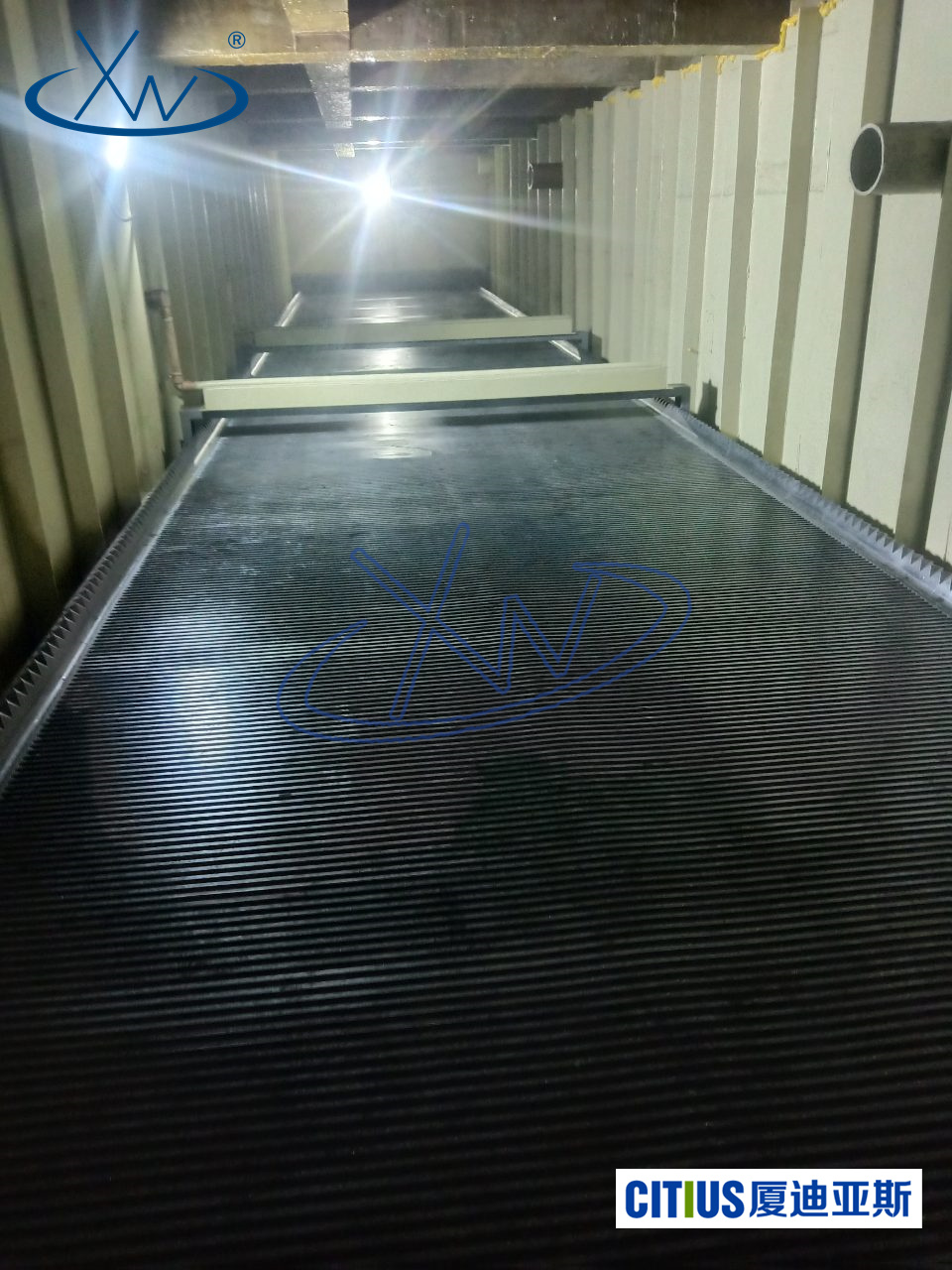

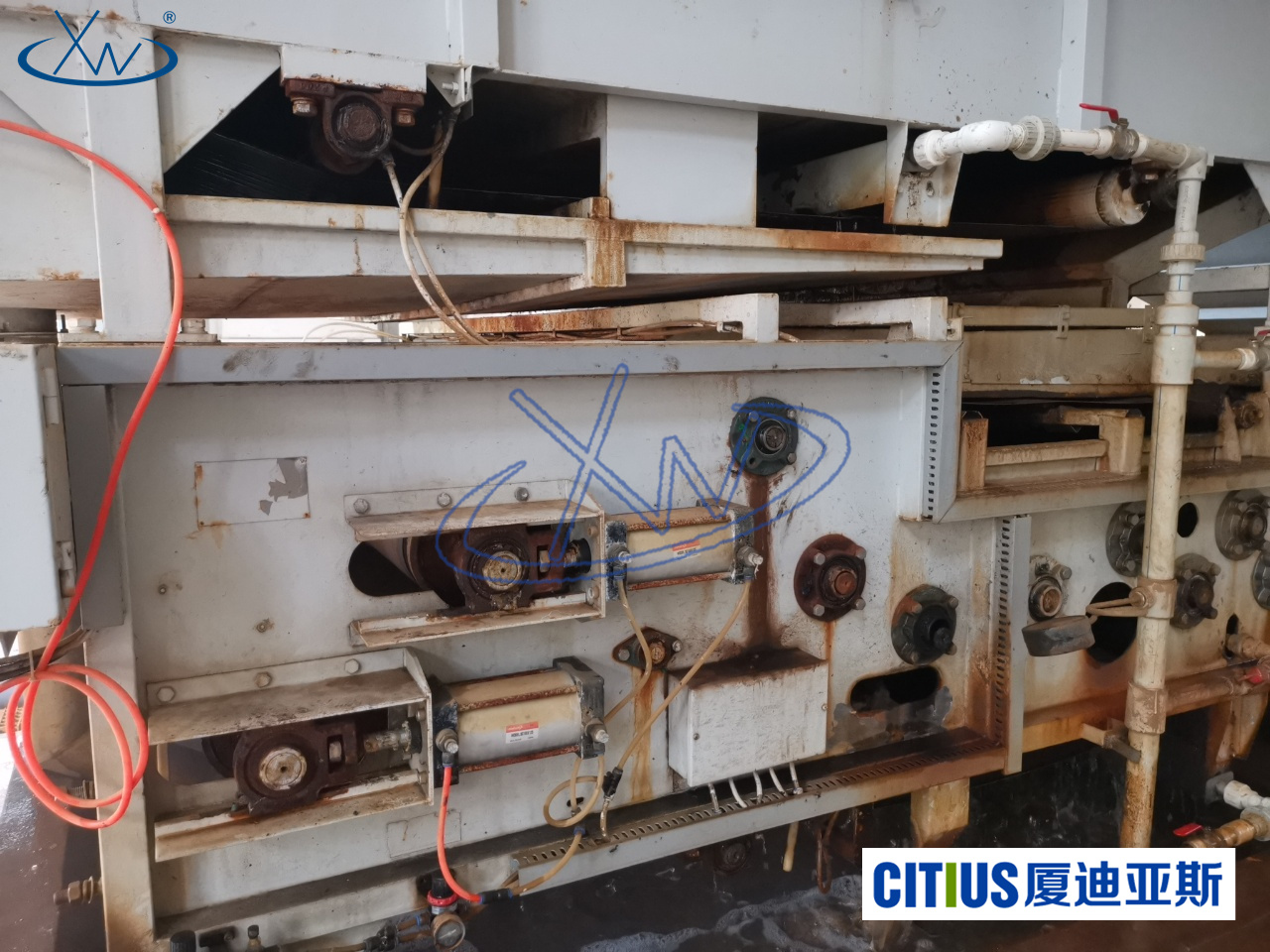

Industrial filter cloth, filter mesh usage - belt press filter cloth - paper mill sludge dewatering

The papermaking industry is a typical high water and high pollution industry. In the pulping, bleaching, and papermaking processes, a large amount of wastewater containing fiber residue, fillers, auxiliaries, and inorganic impurities is produced. After a series of physical and chemical + biological treatments, a large amount of sludge is finally formed, which needs to be dewatered by effective solid-liquid separation equipment to reduce its water content for subsequent transportation, incineration, landfill, or resource utilization.

Details

Sand and gravel are the "skeleton" of urban construction, while environmental protection is the "foundation stone" of sustainable industrial development. Xiamen Citius firmly believes that high-quality filter materials not only improve equipment performance but also play a key role in promoting environmental protection and resource recycling. Through the accumulation of technology and experience, we will continue to provide the sand and gravel industry with more efficient and reliable filtration solutions to help green sand washing take root.

Details

The development of the mechanism sand industry is no longer just a competition of output, but also a contest of environmental protection and efficiency. In this invisible "filtration competition", what Xiadias provides is not only filter cloth and conveyor belts, but also solutions that connect environmental protection and production efficiency. Every choice of filter cloth is an environmental commitment; every completion of filtration is a rebirth of resources.

Details

Against the backdrop of rapid urban construction and infrastructure development, manufactured sand, as a key substitute for natural sand and gravel, is increasingly becoming the mainstream choice in the sand and gravel industry. However, the large amount of sand washing sludge produced during the production of manufactured sand, characterized by its fine particle size, high water content, and complex composition, has become a key challenge hindering environmental compliance and resource recovery.

Details

With the acceleration of urbanization, the amount of municipal wastewater treatment is constantly increasing, and sludge treatment has become an important part of wastewater treatment plant operation. Belt press filter machines, due to their efficient and continuous solid-liquid separation capabilities, have become commonly used equipment for sludge dewatering in municipal wastewater treatment plants. Industrial filter cloth, as a key consumable, its performance directly affects the sludge dewatering effect and the stable operation of the equipment.

Details

Industrial filter cloth is the key to efficient sludge dewatering in belt filter presses. Through scientific selection and technical optimization, the filter cloth not only improves sludge dewatering efficiency but also extends equipment life, reduces operation and maintenance costs, and helps wastewater treatment plants achieve green environmental protection and resource utilization goals.

Details

As a core consumable for belt filter presses, the performance of industrial filter cloth directly determines the solid-liquid separation effect of alkaline sludge treatment in wastewater treatment plants. By using industrial filter cloth with excellent alkali resistance and good filter cake release performance, not only can the dehydration efficiency be improved and the operating cost reduced, but also the service life of the equipment can be extended, providing strong support for the stable operation of the wastewater treatment plant.

Details

In the "tug-of-war between water and solids" of sludge dewatering, industrial filter cloths and filter meshes serve as filters, carriers, and support systems for equipment operation. Selecting a high-performance, well-matched filter cloth is the crucial first step for efficient solid-liquid separation.

Details

Sewage treatment is not just about water purification, but also about the efficient management of sludge. In belt filter presses, the performance of a high-quality filter cloth directly determines the efficiency and economy of the entire sludge dewatering system. Choosing a reliable filter cloth supplier is a key step in achieving energy-efficient, high-efficiency, and environmentally friendly operation.

Details

In seemingly ordinary belt press filter machines, the roles of industrial filter cloth and filter mesh are irreplaceable. They are not only fundamental to the stable operation of the equipment, but also directly determine the level of dehydration efficiency and environmental protection indicators. Selecting the appropriate filter cloth is a crucial step towards more environmentally friendly and economical urban sludge treatment.

Details