Company News

CITIUS: The Leading China Nano-Micron Powder Filter Press Manufacturer, Certified with ISO 9001

In an increasingly competitive market, the decision to choose a supplier goes beyond just price and product features. It is a strategic choice rooted in trust and reliability. Citius’s commitment to quality, as validated by its ISO 9001 certification, is a powerful differentiator. It assures customers that every Citius product, from the core fibers to the final calendering process, is held to the highest possible standard. This relentless pursuit of excellence is what empowers Citius to build long-lasting partnerships with clients across the globe. By choosing Citius, customers are not just buying a filter cloth; they are investing in a promise of performance, consistency, and a partnership built on the unwavering foundation of quality.

21

2025

/

10

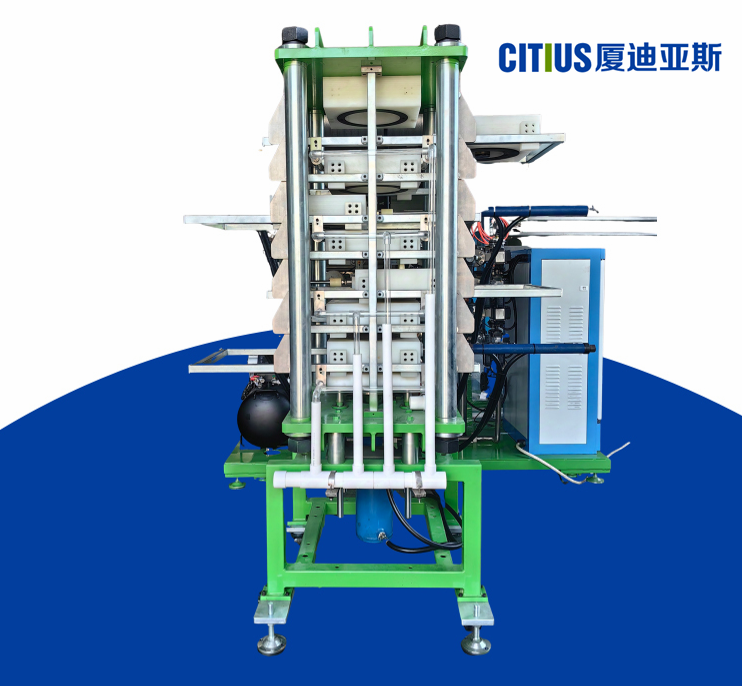

First Look: In-Depth Overview of Citius' New Nano-Micron Powder Filter Machine

The New Nano-Micron Powder Filter Machine is not just an efficient filtration unit—it represents a system-level upgrade for solid-liquid separation in industry. With outstanding performance in nano-powder handling, high-purity material preparation, and industrial wastewater purification, it offers strong technical adaptability and commercial potential.

05

2025

/

06

CITIUS's Commitment to Quality: The Mark of a Future Leading Filter Press Cloth Factory

In the intricate world of industrial filtration, where every micron matters and reliability is non-negotiable, a profound transformation is underway. Industries worldwide are increasingly demanding higher efficiency, greater sustainability, and flawless performance, making the role of a trusted supplier of technical fabrics more critical than ever. As a leading brand in China's industrial textiles-filter material (mesh belt) technical fabric research and manufacturing, Xiamen Citius Filter Media Technology Incorporated Company has consistently set itself apart through a steadfast commitment to excellence. As a national high-tech enterprise and the drafting unit of the belt filter belt industry standard, the company is well on its way to becoming a Future Leading Filter Press Cloth Factory by setting the standard for quality and innovation. Its structural and functional filter materials and process mesh belts are widely used in a diverse range of fields, including industry, agriculture, infrastructure, medical and health, and environmental protection. With products exported to countries and regions across Australia, the United States, South Africa, Brazil, Europe, and Southeast Asia, the company provides indispensable solutions to a global clientele.

20

2026

/

01

Xiadis’s new nanomicro-powder filtration equipment has been widely adopted in the fields of metal powders, nano-oxides, functional materials, and high-value-added powders. Through continuous and in-depth on-site user surveys and process validation, Xiadis has developed a comprehensive set of engineered solutions centered on the filtration, purification, washing, dehydration, and moisture reduction of nanomicro-powder materials. These solutions allow for flexible configuration of equipment and operational modes based on different material systems and process objectives.

09

2026

/

01

CITIUS: Delivering Excellence as China's Best Micron Filter Supplier

In the dynamic world of industrial textiles and filtration, where precision and reliability are critical, few names command as much respect as the company. As a leading China Best Micron Filter Supplier, Xiamen Citius Filter Media Technology Incorporated Company has built its reputation on a relentless pursuit of excellence. From its origins as a research and manufacturing powerhouse to its current status as an industry standard-setter, its journey is a compelling brand story of innovation and dedication. It’s a testament to how a national high-tech enterprise became a trusted partner for industries worldwide, including environmental protection, mining, food processing, and chemical production.

08

2026

/

01

Centrifuge vs. Filter Press vs. New Nanomicro Powder Filtration Machine

This article provides a systematic comparison of three mainstream solid-liquid separation devices—centrifuges, filter presses, and a new nanomicro-powder filtration machine. It analyzes the working principles, advantages, and limitations of each device, and delves into the technological value of the new nanomicro-powder filtration machine, its practical applications in high-end industries, and Xiadis’s overall solution capabilities as a technology supplier.

07

2026

/

01

China's Best Micron Filter Suppliers: A Guide to Finding the Right Partner

Selecting a reliable micron filter supplier is a strategic decision that directly impacts product performance, process efficiency, and long-term operational stability. This article outlines five critical criteria for evaluating a high-quality micron filter media supplier, including technical expertise, quality assurance systems, customization capability, global service network, and proven industry reputation. Through an in-depth analysis, the article highlights why Xiamen Citius Filter Media Technology Incorporated Company stands out as a trusted filtration partner for global clients. As a national high-tech enterprise and the drafting unit of China’s belt filter belt industry standard, the company demonstrates strong leadership in industrial textile and filter media innovation. Its micron-level filtration solutions are widely applied in mineral processing, environmental protection, wastewater treatment, and large-scale industrial operations worldwide. By combining advanced material research, strict quality control, application-specific customization, and an established international supply network, Xiamen Citius delivers consistent, high-performance filtration media that meet the demanding requirements of leading filtration equipment manufacturers. This article serves as a practical guide for global buyers seeking a dependable, long-term partner in micron filtration technology.

23

2025

/

12

Integrated Filter Media Solutions for Industrial Filtration Systems

From coolant filtration to mineral dewatering, from pharmaceutical fine filtration to advanced material separation, Xiamen Citius consistently designs its products around equipment compatibility, process adaptability, and long-term operational stability.

18

2025

/

12