Environmental filter cloth, belt press filter, environmental sewage sludge dewatering

Share to

Detailed Description

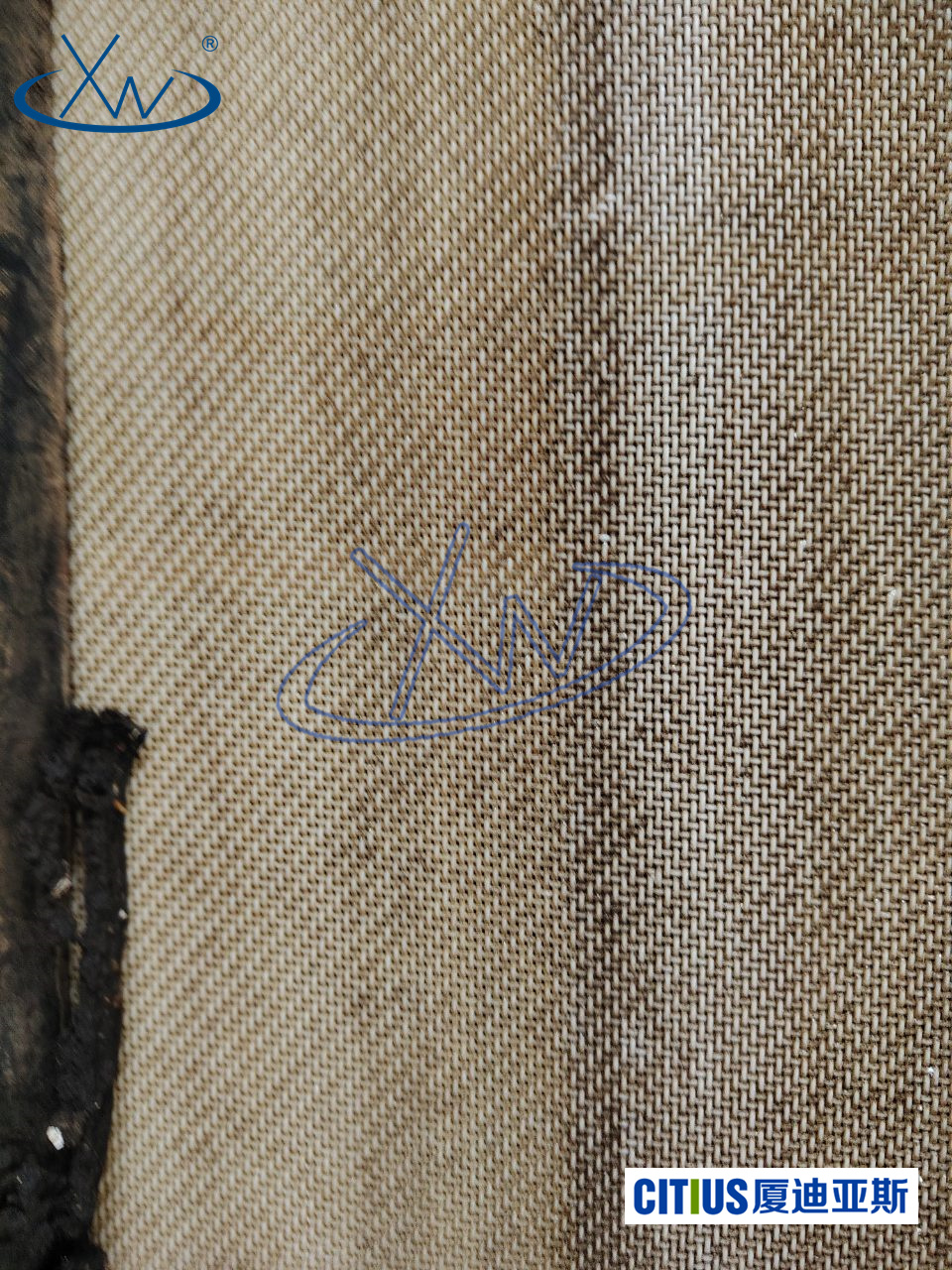

- Environmental filter cloth, belt press filter, environmental sewage sludge dewatering

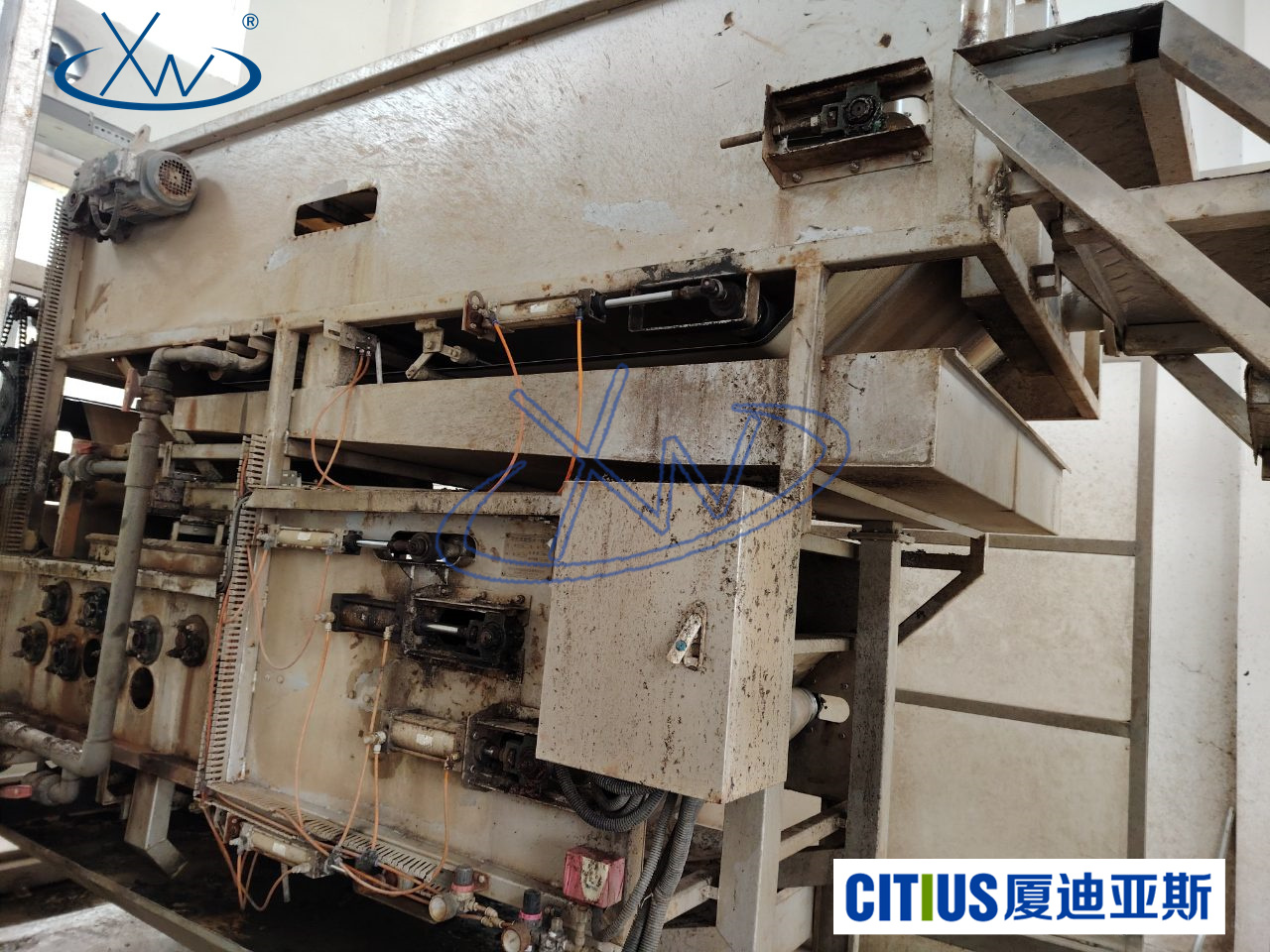

Filter type: Belt press filter

Application industry: Environmental sewage

Material description: Sludge dewatering

Filter cloth model: 055, 002A

Empowering wastewater treatment: High-efficiency dewatering application of environmentally friendly filter cloth in belt press filters

In modern urban and industrial systems, wastewater treatment is not only related to ecological protection, but also directly affects economic operation and the quality of people's livelihood. In the final stage of wastewater treatment —— Sludge dewatering process, improving efficiency and reducing costs have become the industry's continuous pursuit. In this process, Belt press filter is widely favored for its stable operation and cost-effectiveness, and its key component —— Environmental filter cloth is quietly playing an irreplaceable role.

I. Sludge treatment: From environmental challenges to resource management

With the increase in the centralized treatment rate of urban sewage, a large amount of sludge is generated. These sludges usually have a high water content, and if not effectively dewatered, the transportation and post-processing costs are high, and it also increases the environmental burden of landfill and incineration. Especially in municipal sewage plants and industrial parks, the efficiency of dewatering is directly related to the economic feasibility and sustainability of the entire environmental protection project.

Belt press filter By continuously running to press the sludge layer by layer, effectively reducing the water content, it is one of the main equipment in current sludge treatment. However, the core of equipment efficiency does not entirely depend on the mechanical structure, and the performance of the filter cloth determines the processing “ quality ” and “ efficiency ”。

II. Working logic of belt press filter and the role of filter cloth

The belt press filter uses a tensioned filter cloth system to clamp the sludge between the upper and lower layers of filter cloth. After multiple rollers press, the water is separated. The whole process seems simple, but every detail in the operation depends on the support of the filter cloth:

- The filter cloth is the carrier of the material :It needs to have sufficient tensile strength and stability;

- The filter cloth is the channel for water to drain :It determines the water permeability efficiency and filtration speed;

- The filter cloth is the interface of solid-liquid separation :It affects the dryness and peelability of the filter cake;

- The filter cloth is the basis for the operation of the entire system :Once it is blocked or worn, it will cause operation interruption or even equipment damage.

Therefore, a high-performance environmental filter cloth is not only a guarantee of equipment efficiency, but also a cost controller for environmental protection projects.

III. Environmental filter cloth: Technological innovation from principle to practice

Xiamen Xiadias Filter Materials Technology Co., Ltd. has been deeply engaged in the field of industrial filter cloth for more than 30 years. Through technological accumulation and market practice, it has created a series of environmentally friendly filter cloth products specifically for belt press filters. Its core advantages can be summarized as follows:

1. High water permeability and solid retention synergy optimization

Through a multi-layer weaving structure design, the filter cloth can effectively retain micron-level particles while allowing high-speed water permeability, making sludge dewatering faster and the filtrate cleaner.

2. Strong anti-clogging ability, maintaining high throughput for a long time

The optimized filter cloth surface structure combined with specific processing technology effectively prevents pore blockage caused by impurities such as oil, colloids, and fibers, reducing cleaning frequency and extending the service life.

3. Excellent chemical and mechanical tolerance

Can cope with PH fluctuations, high organic load, and frequent temperature changes in complex working conditions. The filter cloth is not easy to age, deform or damage, and the operation is more stable.

4. Good filter cake peelability, improving dewatering rate

After pressing, the filter cake can be easily peeled off without residue or sticking to the cloth, reducing manual operation burden and improving automation level.

IV. Project practice: Helping wastewater plants achieve efficient dewatering

In several large-scale municipal wastewater treatment plant renovation projects, the application effect of Xiadias environmental filter cloth is significant. Taking a wastewater plant in a southern city as an example, after replacing the original filter cloth, the system operating efficiency has increased by more than 25% ,the filter cake water content has decreased from 80% to about 65% ,and the transportation and landfill costs have decreased simultaneously. At the same time, the service life of the filter cloth has been extended to more than one year, greatly reducing the frequency of downtime maintenance.

Moreover, in some park projects that deal with difficult industrial sludge, the customized filter cloth solutions provided by Xiadias have shown strong adaptability in dealing with heavy metals and high COD values and other complex materials, saving enterprises a lot of processing costs and improving the environmental protection compliance rate.

V. System solutions: More than just filter cloth, but also service and support

The application of environmental filter cloth is not only a product output, but also a system project. Xiadias always adheres to “ Problem-oriented + Application-driven ” service concept, providing full-process technical support from selection design, working condition matching, customized processing to maintenance guidance to ensure the long-term stable operation of customers' equipment.

Typical service contents include:

- Filter cloth selection suggestions :According to the sludge characteristics and equipment parameters, scientifically match the most suitable filter cloth structure and specifications;

- Custom Processing Capabilities :Provides a variety of processing services, including edge binding, jointing, guide strips, and punching, compatible with various filter press equipment;

- Operation & Maintenance Assistance and Technical Training :Assists clients in mastering filter cloth installation, operation, and cleaning techniques to enhance system efficiency;

- Fault Diagnosis and Continuous Optimization :On-site analysis of filter cloth anomalies, providing upgrade and optimization suggestions to promote continuous project improvement.

VI. Conclusion: The Green Power in Details

In the systematic engineering of wastewater treatment, filter cloth may be an inconspicuous component, yet it holds immense potential for energy saving and environmental protection. It connects not only sludge and filter cake, equipment and manpower, but also the attitude and actions of enterprises towards their commitment to environmental protection.

In the future construction of green urban infrastructure, Xiamen Citius will continue to provide the environmental protection industry with more “ Invisible Power ” ,driving wastewater and sludge treatment towards a more efficient, economical, and sustainable future.

For samples, technical data, or cooperation inquiries, please contact:

- Company Name: Xiamen Citius (Xiamen Citius) Filter Materials Technology Co., Ltd.

- Official Website: www.citius-filter.com

- Email: wyl@citius-filter.com

- WhatsApp : +86-13950107241