Industrial filter cloth air permeability (air permeability) unit conversion and selection guide

Release time:

2025-03-19

Abstract:

The air permeability (air permeability rate) of industrial filter cloth is an important indicator for measuring its air permeability performance, directly affecting filtration efficiency and usage effect. Different countries and regions have different expressions for the units of air permeability. Common units include L/m²/s, L/dm²/min and cfm. This article will start from the perspective of practical application, combined with the practical experience of Xiamen Dias filtration technology, introduce the common units of air permeability and their conversion relationships, and discuss the relationship between air permeability and filtration accuracy to provide reference for the selection of filter cloth.

1. Definition and Importance of Air Permeability

2. Relationship between Air Permeability and Filtration Accuracy

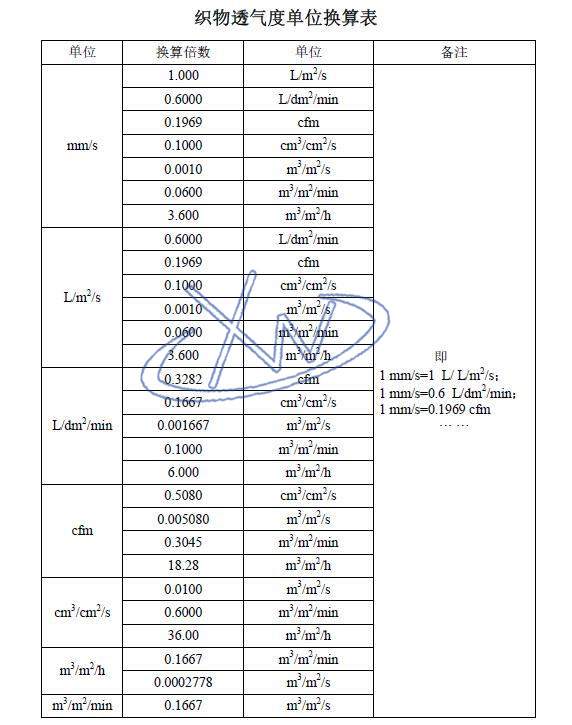

3. Common Air Permeability Units and Conversion Relationships

-

Commonly used units in China: L/m²/s @ test pressure 200Pa, test area 20cm² -

Commonly used units in Europe: L/dm²/min (or dm/min) @ test pressure 200Pa, test area 20cm² -

Commonly used units in the United States: cfm (cubic feet/minute) @ test pressure 125Pa, test area 38cm²

Unit Conversion Relationships

-

1 L/m²/s = 0.6 L/dm²/min = 0.197 cfm -

1 L/dm²/min = 1.667 mm/s -

1 cm³/cm²/s = 10 mm/s -

1 m³/m²/min = 16.667 mm/s -

1 m³/m²/h = 1000.02 mm/s

Conversion Example

-

100 L/dm²/min = 100 × 1.667 mm/s = 166.7 mm/s -

100 L/dm²/min = 100 / 0.6 L/m²/s ≈ 166.67 L/m²/s -

100 L/dm²/min = 100 / 0.197 cfm ≈ 507.61 cfm

4. Precautions for Air Permeability Selection

-

Slight difference in air permeability: There may be a slight fluctuation in air permeability in actual tests, so the actual test data should be used as a reference during selection. -

Combined with working conditions: Different working conditions have different requirements for the air permeability of filter cloth. When selecting, the properties of the filtration medium, filtration pressure, temperature and other parameters should be considered comprehensively. -

Sample experiment: Before bulk purchase, it is recommended to verify whether the air permeability and other performances of the filter cloth meet the requirements through sample experiments. -

Other parameters: In addition to air permeability, the thickness, material, weight, breaking strength, temperature resistance, acidity and alkalinity of the filter cloth should also be considered to ensure that it is suitable for specific working conditions.

5. Practical Support of Xiamen Dias Filtration Technology

6. Summary

By combining the practical experience of Xiamen Dias filtration technology, this article provides a practical reference for relevant professionals, helping them to better understand and apply this parameter of air permeability, and improve the efficiency and reliability of the filtration system.