Spiral Mesh Solutions for the Sugar Industry: Why CITIUS Is the Smart Choice for North and South America

Release time:

2025-07-09

In the global sugar industry, especially across North and South America, sugarcane processing is not just agriculture—it’s a strategic industrial operation. From juice extraction to filtration, dewatering, drying, and crystallization, efficiency in every step is crucial. And among the critical components powering this efficiency, spiral mesh belts play an unsung but indispensable role.

As production lines grow in scale and complexity, CITIUS (Xiamen Citius Filter Media Technology Co., Ltd.) emerges as one of the world’s most reliable and cost-effective suppliers of spiral mesh belts—offering unmatched square meter output, quality consistency, and product diversity. Let’s explore how CITIUS supports the sugar industry across the Americas.

1. A Demanding Industry: The Role of Spiral Mesh in Sugarcane Processing

In sugar production, spiral mesh belts are used in some of the most physically and chemically demanding sections of the line:

Bagasse dewatering after juice extraction

Clarification and sludge filtration

Filter cake (mud) transport and dewatering

Sugar crystal drying and conveying

Lime mud and sulphur sludge separation

These applications require mesh belts that are abrasion-resistant, chemically stable, heat-tolerant, and structurally durable—especially under constant exposure to high humidity, sticky materials, and corrosive substances. That’s where CITIUS excels.

2. China’s Largest Spiral Mesh Manufacturer

CITIUS is the leading spiral mesh manufacturer in China by production area, delivering consistent, high-performance belts to customers worldwide. With over 30 years of expertise in industrial filter fabrics and mesh belts, the company serves clients in mining, chemicals, wastewater, paper, and sugar industries.

Key Strengths of CITIUS Spiral Mesh Belts:

✅ Industry-Leading Capacity: The largest spiral mesh output in China, with daily production over 10,000 m², ensuring on-time delivery for large-scale OEM or urgent replacements.

✅ Lowest Factory Pricing in China: Thanks to complete in-house weaving and finishing capabilities, CITIUS offers the most cost-effective solutions without compromising on quality.

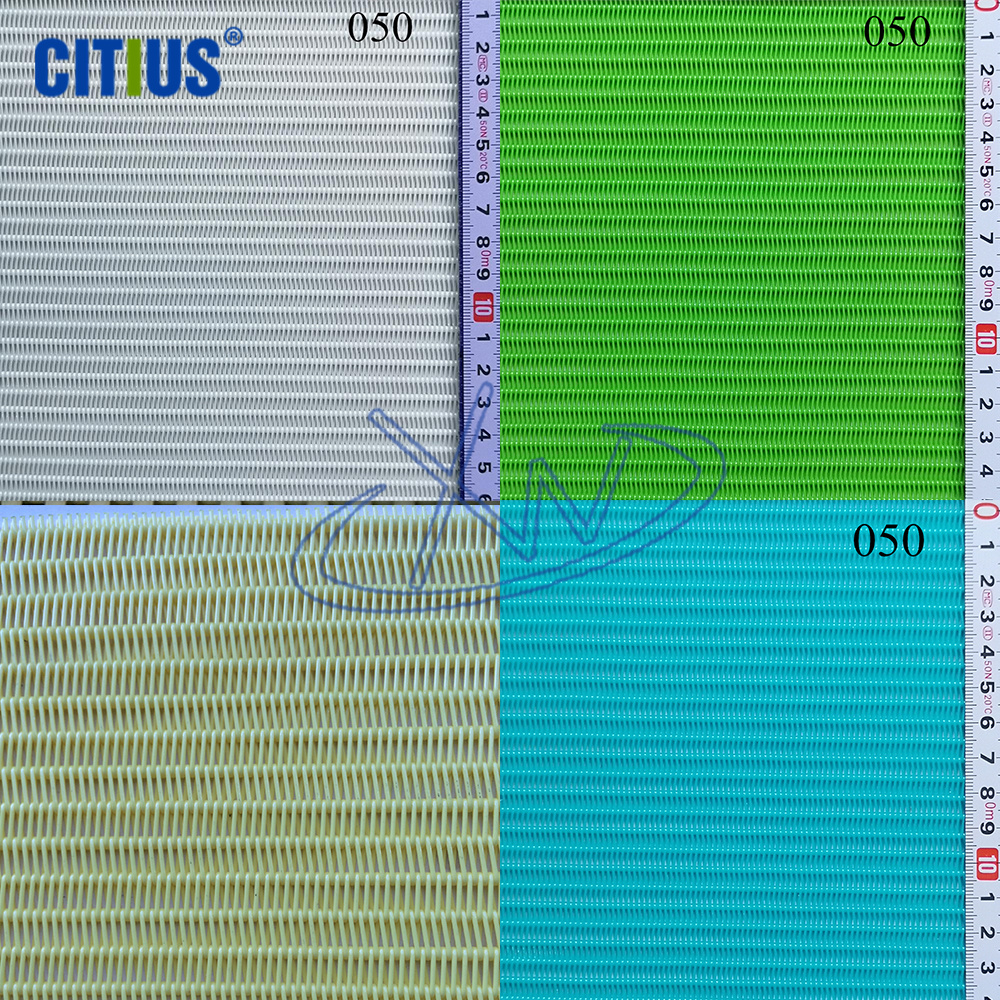

✅ Color & Performance Options: White, blue, green, orange, and gray mesh colors—ideal for section-based identification in large factories.

✅ Tailored Engineering: Customizable mesh density, air permeability, seam types (clipper, pin, endless), thickness, and chemical resistance to match local equipment.

✅ Strong Global Shipping: Active shipments to sugar plants in Brazil, Mexico, Colombia, the U.S., and more—with growing logistics infrastructure.

3. Product Variants Designed for Sugar Factories

CITIUS spiral mesh belts come in various technical specifications to meet diverse filtration and transport needs:

| Product Type | Common Colors | Key Features | Application Area |

|---|---|---|---|

| High-Permeability Mesh | White / Blue | Fast drainage, open structure | Bagasse dewatering |

| Abrasion-Resistant Mesh | Orange / Gray | Long service life in harsh settings | Filter mud belt conveyors |

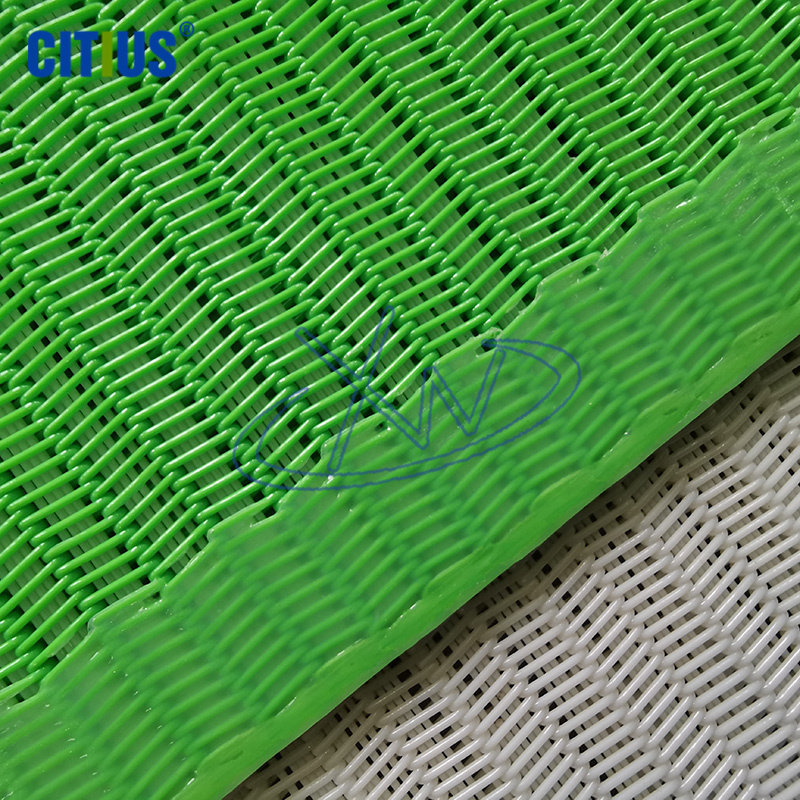

| Anti-Stick Mesh | Green | Reduced sugar adhesion | Crystallized sugar handling |

| High-Temperature Mesh | Gray / White | Heat resistance up to 120°C | Drying and cooling zones |

| Clogging-Resistant Mesh | Blue | Works well with fine sludge | Lime sludge or sulphur sludge separation |

Multiple seam options (clipper joints, spiral pin, endless welding) are available for both old and modern machines, ensuring smooth installation and stable long-term operation.

4. Field-Proven Results: CITIUS in Action

CITIUS spiral belts are currently running successfully in large sugar plants across Latin and North America:

🔹 São Paulo, Brazil: A major sugar refinery switched to CITIUS high-permeability mesh, increasing dewatering efficiency by 12% and reducing belt replacement costs by 18%.

🔹 Yucatán, Mexico: Upgraded to high-temp anti-stick mesh for crystallized sugar conveying, solving long-standing adhesion issues on the production line.

🔹 Louisiana, USA: After 120 hours of continuous operation, CITIUS anti-stick green mesh showed excellent tensile strength and low residue buildup, outperforming legacy brands.

5. Why CITIUS?

Manufacturing Expertise: Decades of experience, complete vertical integration, and full control over yarn weaving, heat setting, and finishing.

Quick Response: Sample dispatch within 72 hours, remote inspection via video, and live engineering support across time zones.

Global-Ready Compliance: ISO9001, REACH, and RoHS certified—compliant with environmental and safety standards in the U.S. and EU.

Technical Support: Belt tension settings, installation guides, and usage optimization tailored to your plant’s equipment.

Strategic Expansion: Actively seeking local partners and distributors in South and North America to build regional stock and service hubs.

6. From China to the Americas: A Belt You Can Trust

For sugar producers across the Americas, balancing cost, durability, and operational efficiency is more critical than ever. A poor-quality belt can cause downtime, contamination, and rising maintenance costs.

CITIUS spiral mesh belts provide a stable, proven solution for sugarcane processing—designed to withstand tough plant environments while delivering long service life and superior drainage performance.

Whether you're upgrading your existing system, reducing operational costs, or building a new line, CITIUS is your trusted partner for high-performance spiral mesh belts.

Previous article: