Industrial filter cloth air permeability, pore size, and mesh conversion table and its applications!

Release time:

2025-03-19

In the field of industrial filtration, the performance of filter cloth is directly related to filtration efficiency, filter cake quality, and the stable operation of equipment.Air permeability, aperture, and meshare important technical parameters for evaluating the performance of filter cloth. The three are closely related and are crucial for applications in different process scenarios. This article will deeply analyze the conversion relationship between air permeability, aperture, and mesh, and by expanding to fine filtration technology data above 900 mesh, 1500 mesh, and 3000 mesh, provide professional guidance for high-end filtration applications.

I. Definition and Relationship of Mesh, Aperture, and Air Permeability

1. Mesh

Mesh refers to the number of holes per square inch (2.54 cm × 2.54 cm). The calculation formula is:

The larger the mesh, the smaller the aperture, and the higher the filtration accuracy.

The relationship between mesh and aperture follows the empirical formula:

Mesh × Aperture (microns) ≈ 15000

For example:

A 400-mesh screen has an aperture of approximately 38 microns.

An 800-mesh screen has an aperture of approximately 18 microns.

2. Aperture

Aperture is the diameter of the pores in the filter cloth, determining the filter cloth's ability to intercept solid particles. The thickness of different fibers, weaving methods, and porosity all affect the aperture.

3. Air Permeability

Air permeability refers to the amount of air passing through the filter cloth per unit time, usually expressed inL/m²/s(liters/square meter/second) orm³/m²/min(cubic meters/square meter/minute). Air permeability is directly proportional to the aperture and inversely proportional to fiber density:

II. Technical Analysis of the Conversion of Air Permeability, Aperture, and Mesh

1. Conversion Rules

Larger mesh → Smaller aperture → Lower air permeability

Smaller mesh → Larger aperture → Higher air permeability

High-mesh filter cloths are suitable for filtering fine particles, while filter cloths with large apertures and low mesh numbers are more suitable for coarse particles or high-throughput material filtration.

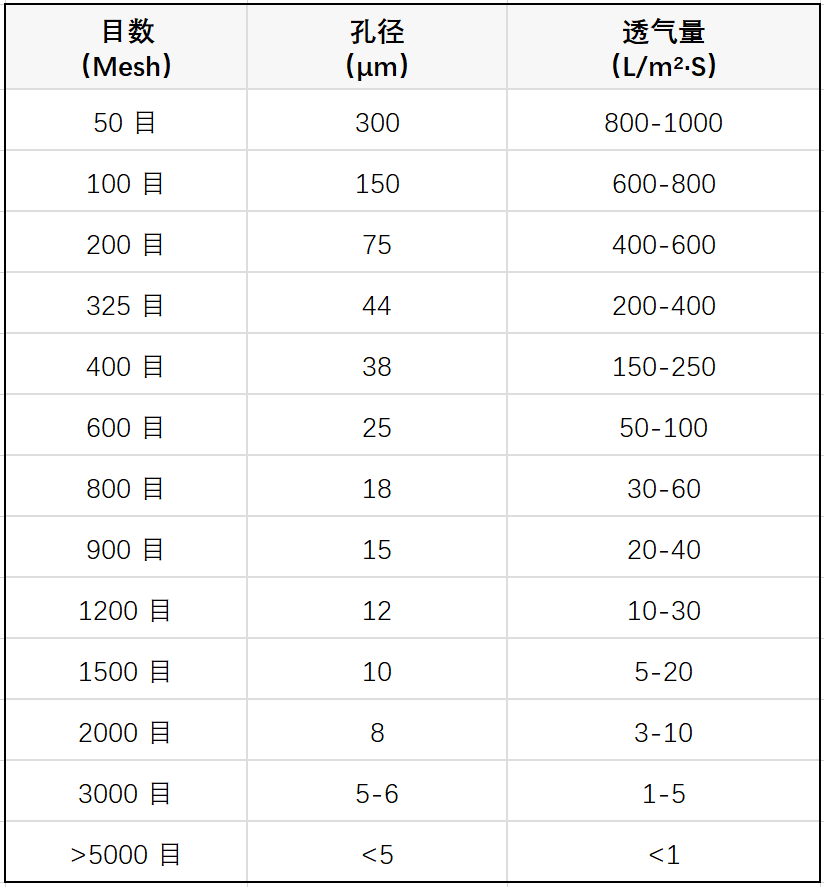

2. Extended Mesh, Aperture, and Air Permeability Conversion Table (For Reference Only)

Note: For industrial filter cloths and needle-punched nonwovens, air permeability is mainly used as one of the standards.

III. Application Scenarios of Air Permeability and Mesh for Different Industrial Filter Cloths

1. Mineral Dewatering and Concentration

In the dewatering treatment of minerals such as feldspar and lepidolite, filter cloths with larger apertures and lower mesh numbers are usually used to achieve high air permeability and rapid dewatering.

Recommended Filter Cloth: 50-100 mesh, aperture 150-300 microns, air permeability can reach 800 L/m²/s or more.

Equipment Application: Horizontal belt vacuum filter, which can quickly complete the solid-liquid separation of minerals.

2. Catalyst and Fine Powder Filtration

For the filtration of catalysts or fine powders, high-mesh, low-aperture filter cloths are needed to ensure efficient interception of fine particles.

Recommended Filter Cloth: 325-500 mesh, aperture 30-44 microns, air permeability controlled below 150 L/m²/s.

Equipment Application: Vertical filter press or horizontal rotary vacuum filter, which can meet the needs of high-precision solid-liquid separation.

3. Nanoparticles and Ultra-Fine Filtration

In the filtration of nano-scale powders and high-precision chemical products, ultra-high mesh filter cloths of 600 to 1000 mesh are required, with an aperture of less than 25 microns, to ensure that tiny particles are effectively intercepted.

Recommended Filter Cloth: 600-1000 mesh, aperture 15-25 microns, air permeability maintained below 50 L/m²/s.

Equipment Application: New micro-nano powder filter, especially suitable for high-precision, ultra-fine particle filtration.

4. Municipal Sludge and Sand Washing Sludge Treatment

For the treatment of municipal sludge dewatering or the sludge from mechanical sand washing, filter cloths with medium mesh numbers are usually selected, balancing air permeability and solid capture capacity.

Recommended Filter Cloth: 100-200 mesh, aperture between 75-150 microns, air permeability maintained at 600-800 L/m²/s.

Equipment Application: Belt press filter, which can stably handle high-water-content sludge.

IV. Key Factors in the Selection of Industrial Filter Cloths

1. Filtration Accuracy Requirements

Select the appropriate mesh number according to the particle size of the solid particles to ensure filtration efficiency while avoiding excessively low air permeability that affects production capacity.

2. Air Permeability and Filtration Speed

Air permeability determines the filtration speed. High air permeability helps to increase the filtration speed, but the air permeability and accuracy need to be balanced according to the process requirements.

3. Chemical Resistance and Mechanical Strength

Select filter cloths with excellent acid and alkali resistance and tensile strength according to the operating environment to improve service life and reduce replacement frequency.

V. Xiamen Xiadias's Solutions

Xiamen Xiadias Filtration Materials Technology Co., Ltd.With 30 years of industry experience, we provide tailor-made filter cloth solutions for various industrial filtration needs. Xiadias has a significant technical advantage in matching air permeability, mesh, and aperture, and can provide efficient and stable filtration materials for different industries.

Professional R&D: Offers over 400 types of industrial filter media, customizable to precise client needs.

Powered by Provides comprehensive services ranging from selection and testing to technical optimization.

Industry Coverage: Covers metallurgy, mining, chemical, and environmental protection industries, earning widespread customer trust.

VI. Conclusion

In industrial filter cloth applications, the scientific matching of air permeability, pore size, and mesh count is key to improving filtration efficiency and extending equipment lifespan. As industrial demands move towards higher precision and efficiency, high-mesh filter cloths will play a significant role in ultra-fine filtration. By thoroughly understanding these technical parameters and combining them with specific process requirements for rational selection, companies can achieve more efficient production and stable operation. Xiamen Xiadias will continue to dedicate itself to technological innovation, providing superior filtration solutions to global clients.