First Look: In-Depth Overview of Citius' New Nano-Micron Powder Filter Machine

Release time:

2025-06-05

Q1: What is the New Nano-Micron Powder Filter Machine? What industry pain points does it address?

A1:

The New Nano-Micron Powder Filter Machine is a high-efficiency solid-liquid separation device specifically designed for processing micro and nano-sized particles—marking a major breakthrough in current filtration technology.

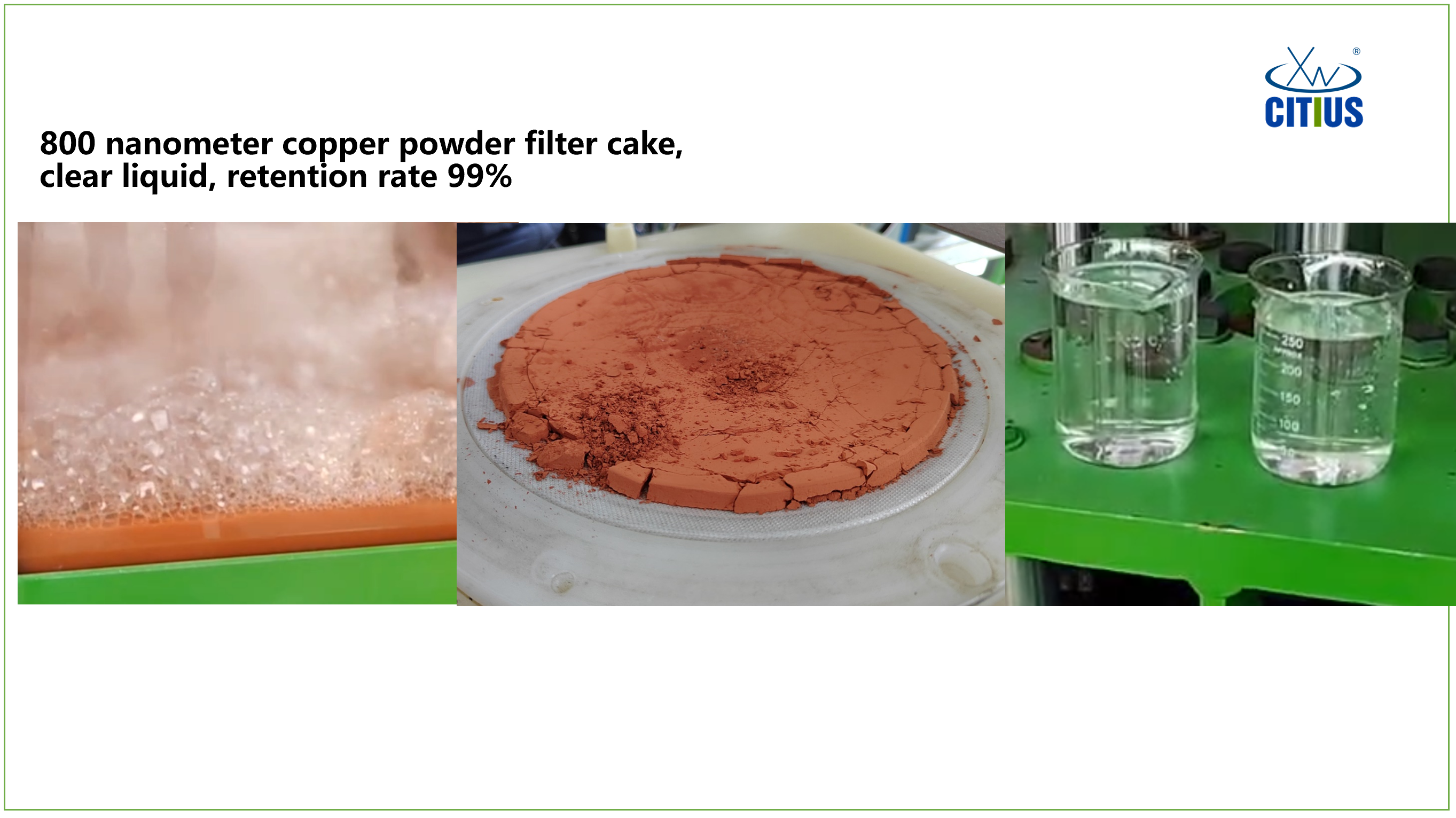

It can directly separate ultra-fine solid particles, achieving a retention rate of up to 99.9%, with a high-precision, low-energy, fully enclosed physical filtration process. This means:

- No chemical additives or filtration aids are required;

- The filtrate is clear and transparent, and the filter cake has a low moisture content;

- It integrates filtration, washing, and drying, simplifying the process significantly;

- It effectively addresses traditional filtration issues such as the difficulty of retaining fine powders and managing sticky filter cakes.

The machine is widely used in the preparation and processing of industrial powder materials and nano-powder materials, and is especially suitable for wastewater treatment involving nano pigment particles and other high-demand fields.

Q2: What types of materials can the equipment filter?

A2:

The filter is suitable for a wide range of powder raw materials and functional nano-powders, including but not limited to:

- Industrial powder materials:

Talc, quartz, heavy calcium carbonate, wollastonite, kaolin, graphite, mica, and other non-metallic mineral powders;

Silicon carbide, fumed silica, fused alumina, silicon nitride, titanium dioxide, synthetic diamond, etc. - Micro and nano powder materials:

Nano-sized nickel, silver, zinc, aluminum, zinc oxide, nickel oxide, alumina, calcium carbonate, silicon oxide, silicon carbide, and more.

Additionally, it’s highly applicable in new energy, electronic materials, fine chemicals, and environmental wastewater treatment industries.

Q3: What are the key components of the equipment? Is installation complex?

A3:

The machine is composed of two main modules:

Component | Dimensions (L × W × H) | Weight |

|---|---|---|

Filtration Main Unit | 1.6m × 1.3m × 2.2m | 1.5 tons |

Auxiliary Unit | 2.2m × 1.2m × 2.3m | 1.0 tons |

It operates using compressed air (≥1.0 MPa, 2–3 m³/h) and features:

- Small footprint

- Low energy consumption

- High degree of automation

It supports custom development and scalable production, adapting to various customer needs.

Q4: What is the performance of the equipment? What is its actual processing capacity?

A4:

Based on testing data:

- The pilot unit processes up to 840 liters per square meter per hour.

- Theoretical maximum throughput can exceed 1200 L/m²·h.

- Each filter plate has an area of 0.6 m², allowing flexible equipment scaling.

- Conductivity rise during filtration is virtually zero, with minimal electrolyte leakage or ion transfer—ideal for high-purity material processing.

- Excellent filter cake release, facilitating material recovery and downstream processing.

It performs exceptionally well in high-demand settings like high-purity electronic materials, specialty powder recovery, and new energy material production.

Q5: How does the machine work? How is it different from traditional filtration equipment?

A5:

Working process:

Feeding → Filtration → Air Compression Holding → Washing → Plate Opening & Discharge

Key differentiators include:

- Filtration media:

Proprietary technology (Patent No. ZL 202211217869.2) with retention precision up to 25nm. - Filtration process:

Slurry is pumped via diaphragm pumps into the filtration chamber. Under air pressure, liquid passes through the filter medium, and solids are retained as filter cake. The entire process is sealed, ensuring no contamination or secondary exposure. - Washing:

A dedicated washing pipeline delivers cleaning liquid (customizable per process) through the system using diaphragm pumps and air pressure. Fully sealed, recyclable washing, resulting in cleaner, drier products. - Material flow channel opening:

Through media surface modification and advanced techniques, the flow path opens periodically during both filtration and washing, ensuring continuous operation, no dead angles, and thorough washing.

Q6: Who are some of the typical customers using this equipment?

A6:

The filter has been successfully deployed by leading companies across multiple industries. Some representative clients and use cases include:

- New energy sector:

A lithium battery materials company filters nano-alumina and Li-Ni-Co precursor materials. - Semiconductor material manufacturers:

Deployed in silver paste and nano-copper powder refining processes. - Fine chemical companies:

Applied to filter waste liquids containing nano-pigments, achieving wastewater reuse. - Non-metallic mineral powder enterprises:

Used in fine purification and classification of heavy calcium, wollastonite, kaolin, etc.

Customers consistently report outstanding performance in efficiency, energy savings, safety, and operational simplicity.

Q7: Is the equipment customizable?

A7:

Yes, the machine supports customizable configurations in terms of models and process parameters.

Designs can be tailored to suit:

- Material types

- Processing capacity

- Washing requirements

- Site limitations

Summary:

The New Nano-Micron Powder Filter Machine is not just an efficient filtration unit—it represents a system-level upgrade for solid-liquid separation in industry.

With outstanding performance in nano-powder handling, high-purity material preparation, and industrial wastewater purification, it offers strong technical adaptability and commercial potential.

If your process requires high-precision filtration, material recovery, or wastewater treatment,

this machine could be the key to optimizing your operations and controlling costs.

- Our goal is to find together the right industrial filtration solution for your application.

CONTACT US

Ms. Molly Wu

Xiamen Citius Filter Media Technology Co., Ltd.

Email: wyl@citius-filter.com

WhatsApp: 86-13950107241