Company News

Xiadis fully understands that the application of nano-metal powders and slurries is not only an emerging market but also a strategic cornerstone for driving the advancement of advanced manufacturing. Looking ahead, the company will continue to ramp up R&D investments, focusing on three key areas: high-efficiency filtration, intelligent control, and industrial-scale adaptability, to propel technological innovation and market adoption of next-generation nanomicro-powder filtration systems. At the same time, Xiadis will collaborate closely with upstream and downstream partners to jointly explore additional application opportunities for nano-powders in fields such as electronics, photovoltaics, semiconductors, new energy, and biopharmaceuticals, helping industries achieve a transformative leap—from breakthroughs in materials to upgrades across entire industries.

28

2025

/

09

The combination of industrial filter cloth and horizontal vacuum belt filters has become a backbone technology for handling fine powders such as titanium powder, quartz sand powder, and other mineral-based materials. By ensuring precise separation, chemical resistance, and continuous operation, this system not only enhances powder purity but also drives efficiency across industries from aerospace and semiconductors to glass and metallurgy. For companies seeking reliable solutions in mineral processing and powder purification, investing in advanced filter cloth technologies is not just a cost decision—it is a strategic step toward higher product value, lower operational risks, and future-ready industrial performance.

17

2025

/

09

At this conference, Xidiya will showcase high-performance filter cloth and filter belts along with typical application cases on-site, and engage in face-to-face discussions with industry experts about the latest trends in solid-liquid separation technology. We sincerely look forward to exploring innovations and practices in the sludge treatment industry with you, jointly promoting efficient and green development in the sector.

01

2025

/

09

Application and Development Prospects of New Nano-Micron Powder Filter Machines

The new nano-micron powder filter machine, based on independently developed filter media preparation technology (Patent No.: ZL 202211217869.2), achieves a maximum retention accuracy of 25nm, enabling high-precision, fully sealed solid-liquid separation. The equipment uses a diaphragm pump + compressed air drive method, completing filtration within a sealed chamber to avoid material contact with the external environment, effectively preventing secondary contamination. Its independent cleaning pipeline and compressed air drying system allow recycling of cleaning liquid, ensuring the material is clean and dry. Through the unique "material flow channel opening technology," the equipment maintains unobstructed flow channels during both filtration and cleaning stages, avoiding blockages and cleaning dead zones, achieving continuous and stable operation. This equipment is widely used in fields such as battery materials, non-metallic minerals, fine chemicals, ceramic building materials, metal powders, pharmaceuticals and food, superhard materials, and high-tech materials. With its high precision, environmental friendliness, and stability, it is gradually becoming an important device for upgrading the powder industry, promoting the sector towards greener, smarter, and higher-end development.

22

2025

/

08

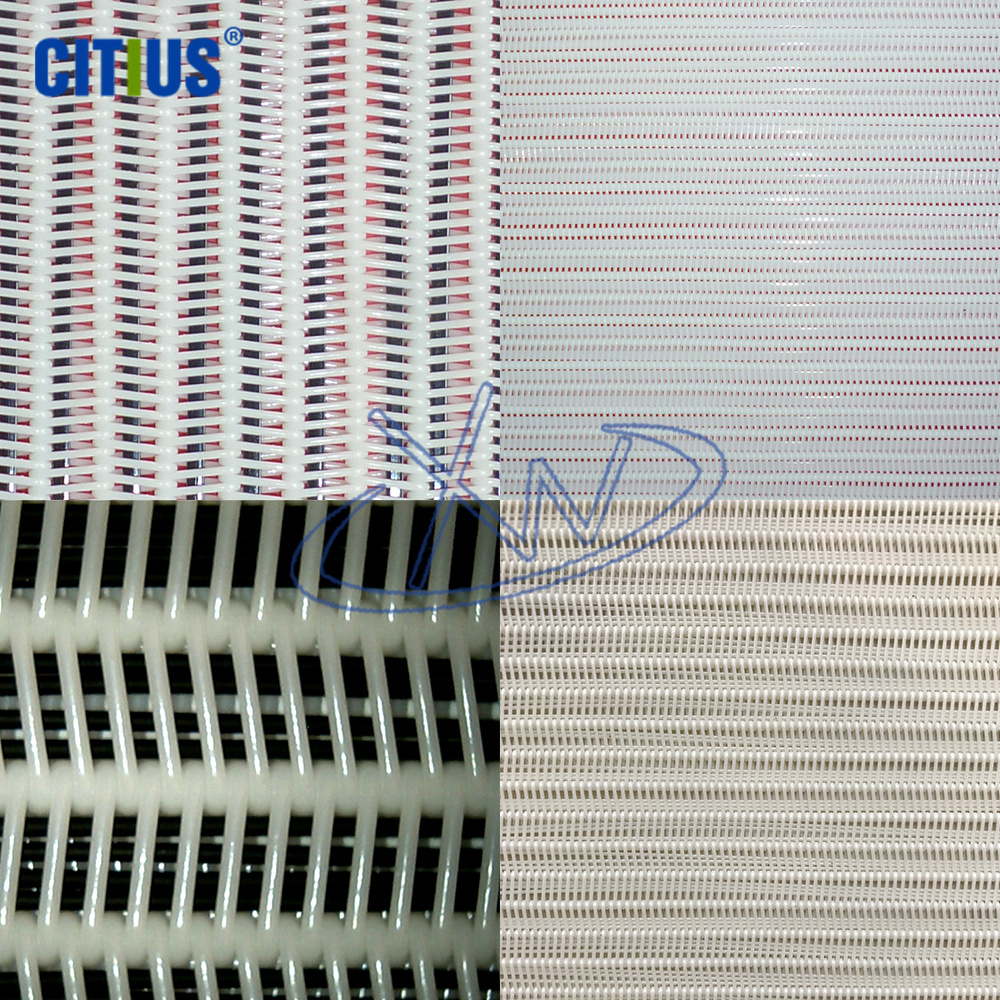

Exhibition Review: Citius Filter at IPB 2025, Showcasing Nano & Micro Filtration Technology!

2025 marks a pivotal year for the global powder industry’s acceleration toward high purity, sustainability, and intelligent manufacturing. As industries such as new materials, electronics, biopharmaceuticals, and fine chemicals demand higher cleanliness, lower energy use, and finer separation precision, filtration — the “last mile” of the process — is taking on an increasingly strategic role.

14

2025

/

08

CITIUS at IPB 2025 | Shaping the Future of Powder Tech

With the continuous upgrading of powder processing technology, industrial filtration systems have gradually become an important force in promoting material purification, efficient separation, and clean manufacturing. From August 6th to 8th, 2025, Xiamen Xiadias Filtration Materials Technology Co., Ltd. will showcase its cutting-edge equipment and core technologies at the 22nd International Powder, Bulk Solids, and Fluid Processing Exhibition (IPB 2025), exploring new paths for high-quality development with industry colleagues.

25

2025

/

07

For sugar producers across the Americas, balancing cost, durability, and operational efficiency is more critical than ever. A poor-quality belt can cause downtime, contamination, and rising maintenance costs. CITIUS spiral mesh belts provide a stable, proven solution for sugarcane processing—designed to withstand tough plant environments while delivering long service life and superior drainage performance. Whether you're upgrading your existing system, reducing operational costs, or building a new line, CITIUS is your trusted partner for high-performance spiral mesh belts.

09

2025

/

07

Rise of 10,000-Mesh Graphite & CITIUS Filter Cloth's New Mission

Graphite is not only a cornerstone of the materials industry, but also a symbol of new productivity. In the ultra-fine processing stage, which magnifies its value a hundredfold, industrial filter cloth plays the role of an "invisible craftsman" that determines purity and efficiency. With the market demand for graphite products of 10,000 meshes or even higher grades continuously climbing, Xiamen Xiadias is using cutting-edge technology and high-performance filter cloth solutions to help the Chinese graphite industry reach the peak of the global value chain.

09

2025

/

07