Exhibition Review: Citius Filter at IPB 2025, Showcasing Nano & Micro Filtration Technology!

Release time:

2025-08-14

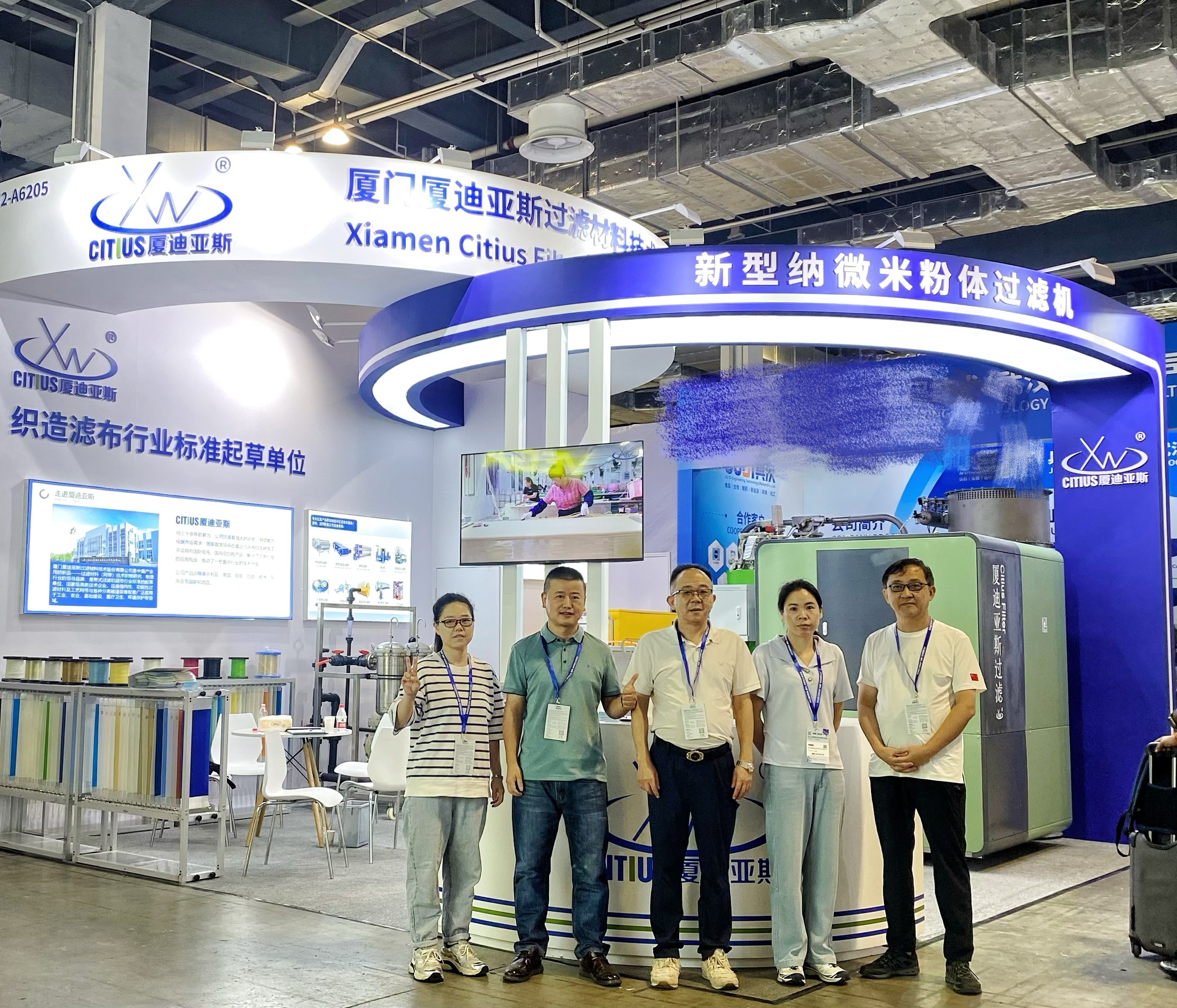

Citius Filter Shines at the 22nd International Powder Exhibition, Focusing on Nano-Micron Filtration Technology with a Thrilling On-Site Showcase!

In August 2025, the 22nd International Powder, Bulk Solids, and Fluid Processing Exhibition (IPB 2025) successfully concluded at the Shanghai World Expo Exhibition & Convention Center. As one of the most influential annual events in China’s powder industry, IPB brought together professional audiences and enterprise representatives from dozens of high-end manufacturing sectors such as materials science, fine chemicals, electronic ceramics, biopharmaceuticals, and new energy, to discuss cutting-edge technologies and explore future industry development.

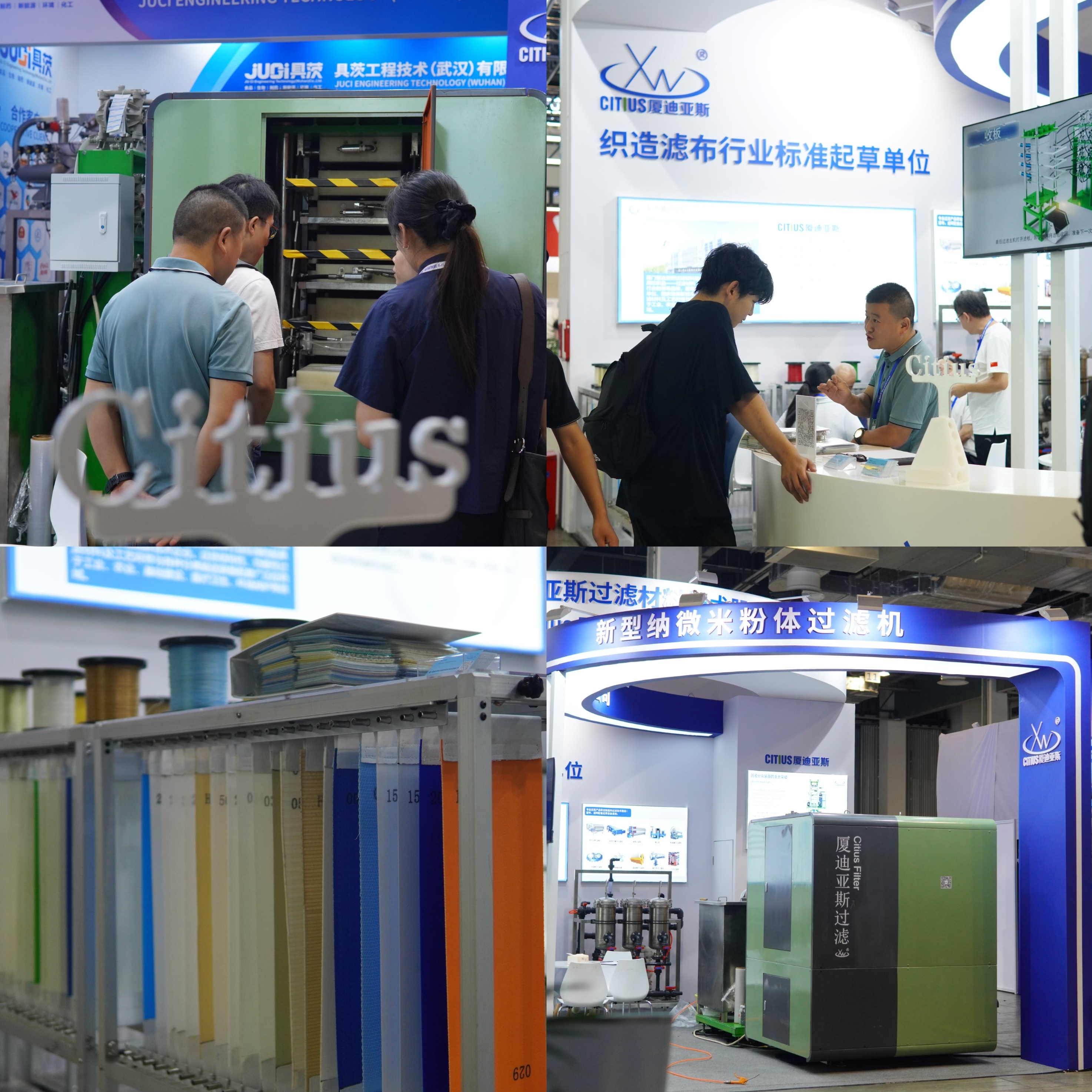

Xiamen Citius Filter Media Technology Co., Ltd. (Citius Filter), one of China’s leading brands in filtration system R&D and manufacturing, made a high-profile appearance with its flagship innovation — the “New Nano-Micron Powder Filter” — along with a series of high-performance filtration material solutions. With its breakthrough integration of nano-scale particle separation + washing + drying, Citius demonstrated innovative exploration and practical applications in the field of nanomaterials and advanced processes, becoming one of the most popular and technically compelling booths at the show. The atmosphere was electric, and the highlights kept coming!

Exhibition Highlights: High Popularity, Precise Match Between “Technology + Needs”

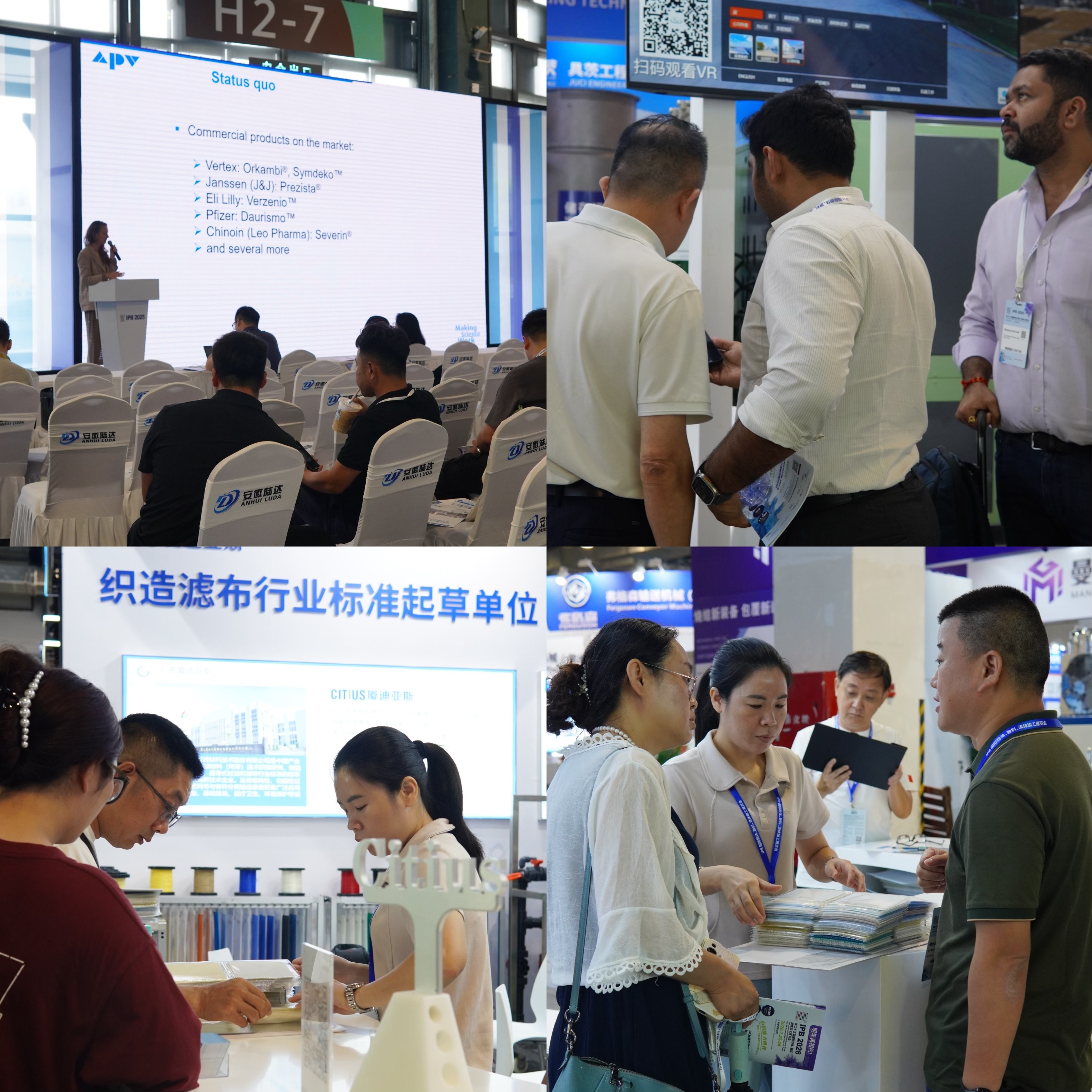

During the three-day exhibition, the Citius booth was constantly bustling. Representatives from domestic and overseas new materials R&D companies, powder producers, universities, and research institutes stopped by to learn more, showing great interest in our products, technologies, and industry applications.

We specially designed Dynamic Process Demonstration Zones, Equipment Structure Display Areas, and Typical Application Case Sharing Sections. Through physical components, filter media samples, and visualized process diagrams, visitors gained a clearer understanding of our capabilities in nano-filtration, high-viscosity high-purity slurry separation, and integrated powder washing processes.

“Your equipment can achieve 25nm separation precision and includes washing functions. Our lab is currently stuck at the slurry purification stage — could we learn more in detail?”

“We produce electronic conductive pastes. Most equipment on the market is inefficient for fine particle handling, but your design looks very interesting — can we arrange a test?”

Representatives from semiconductor materials, bioengineering, electronic slurry, and new energy battery precursor industries raised highly technical questions, to which our team responded in depth, establishing follow-up communication channels.

Many professional visitors commented that this equipment matches their requirements for high purity, high efficiency, and low energy consumption, making it a strong solution to their current process bottlenecks.

Star Product: New Nano-Micron Powder Filter — Leading Future Trends

Our main showcase was the self-developed New Nano-Micron Powder Filter, with multiple industry-leading performance indicators, especially suitable for liquid-solid separation of sub-micron to tens-of-nanometer particles.

Key Features:

High Filtration Precision — Achieves effective separation at 25nm, meeting strict particle size control demands in high-end industries such as high-purity materials, electronic pastes, and specialty ceramics.

Integrated Process Design — Filtration, washing, and drying completed continuously, greatly improving efficiency while reducing energy consumption.

Compact & Automation-Friendly — Modular design supports continuous feeding and easy integration into large-scale industrial production lines.

Versatile Material Handling — Suitable for challenging slurries with high viscosity, high density, easy settling, or low solid content.

Customizable Filter Media — Paired with Citius’s proprietary high-performance filter media, enabling precise grading for different material characteristics.

Since its launch, this equipment has been tested and piloted in lithium battery materials, nano-metal powders, electronic pastes, bio-enzyme carriers, and functional pigments, delivering stable performance and positive customer feedback. During the exhibition, we also presented real client case data and test curves, boosting confidence and partnership interest.

Market Response: 600+ On-Site Discussions, Cooperation Intentions Worldwide

Over the three days, the Citius booth welcomed more than 600 professional clients and technical experts, including representatives from Germany, Japan, South Korea, India, Turkey, Mexico, Brazil, and beyond, who expressed strong interest in our high-end separation solutions.

In nanomaterial preparation, seed crystal filtration, and specialty powder refinement, many visitors requested on-the-spot testing and held in-depth process discussions with our engineering team.

Experts from academic laboratories and material incubation platforms also expressed interest in establishing technical partnerships with Citius to accelerate the industrial application of powder purification in cutting-edge scenarios.

Customer-Centric Approach: From Filter Cloth to Full Filtration Systems

Founded in 2009, with over 30 years of industry experience, Citius Filter is a dual-driven enterprise combining filter media technical fabrics with filtration system solutions. We offer over 400 filter cloth structures and dozens of high-performance composite materials, along with full-service capabilities from filter cloth → components → complete systems → on-site customization.

We firmly believe that filtration technology is not just about equipment — it’s about implementing solutions after truly understanding the customer’s process logic.

From early-stage consultation and pilot testing to after-sales maintenance, we stay closely aligned with customer needs, constantly iterating and upgrading to integrate high-end manufacturing with advanced separation processes.

Looking Ahead: Filtration for a Cleaner Industry

2025 marks a pivotal year for the global powder industry’s acceleration toward high purity, sustainability, and intelligent manufacturing. As industries such as new materials, electronics, biopharmaceuticals, and fine chemicals demand higher cleanliness, lower energy use, and finer separation precision, filtration — the “last mile” of the process — is taking on an increasingly strategic role.

Citius Filter will continue to focus on niche markets, driven by innovation, targeting micro- and nano-particles, complex process conditions, and green energy efficiency to deliver reliable filtration equipment and solutions for customers worldwide, helping industries achieve higher-quality development.

📍 Thank you to every client, friend, and partner who visited our booth — your support fuels our progress!

📞 For more technical information and sample support:

🌐 Website: www.citius-filter.com

📍 Address: No. 16-22, Chunfeng East Road, Xiang’an Torch Hi-Tech Zone, Xiamen, Fujian, China

✨ Xiamen Citius Filter Media Technology Co., Ltd.

Providing the world with cleaner, more precise filtration solutions — Filtration: the bridge between the microscopic world and clean industry.