Company News

From silver to silicon-carbon materials, our nano- and micro-scale filtration systems are supporting the development of next-generation high-performance materials.

12

2025

/

11

Advancing the LiFePO₄ Industry with Filtration Technology

On the production line for new energy materials, the purity of every particle of iron phosphate directly determines the energy density of the battery. Xadias industrial filter cloths, with their exceptional retention capabilities, strong anti-clogging performance, and excellent regenerative properties, provide a highly efficient and reliable solution for iron phosphate purification, helping the industry move toward greater sophistication and智能化 (smartification).

11

2025

/

11

In the modern, highly efficient pulp and paper production system, filter mesh belts are no longer merely consumables—they have become a critical technological component that directly influences energy consumption, product quality, and environmental performance. Through continuous technological innovation and industry-driven practices, Citius Filter has successfully upgraded traditional filtration fabrics into high-performance, intelligent process carriers, unlocking the full potential of twin-wire press machines.

16

2025

/

10

The critical role of industrial filter cloths in the filtration of lead-zinc concentrates. Throughout the entire system, the filter cloth serves as the most important "separation medium," and its performance directly determines the efficiency of the vacuum belt filter and the quality of the filter cake. The unique characteristics of lead-zinc ores demand that the filter cloth possess not only high mechanical strength and excellent air permeability but also outstanding anti-clogging properties.

16

2025

/

10

The Key to Dewatering Municipal Sludge—A Guide to Selecting Filter Cloth for Belt Presses

Xiamen Citius is leveraging its technological expertise in filtration materials and system equipment to continuously drive the upgrade and innovation of sludge treatment systems, helping urban wastewater treatment move toward a higher-standard, environmentally friendly green development.

16

2025

/

10

The Application of Xadias Spiral Mesh Conveyor Belt in Pastoral Regeneration

Xiamen Xiadias, guided by the philosophy of "high-quality filtration media to build a clean production system," is dedicated to providing comprehensive solutions for livestock farming, environmental protection projects, and solid-liquid separation in agriculture. The innovative application of spiral mesh belts not only helps farms achieve efficient, energy-saving manure management but also paves the way for a new model of agricultural circular economy and sustainable green development.

13

2025

/

10

Application Case | Xadias Spiral Mesh Belt in Municipal Sludge Belt Press Filter Systems

The spiral mesh belt, as the core filtration medium of belt press filter machines, plays a critical role in dewatering municipal sludge. Xiamen Xiadias has significantly enhanced filtration efficiency and durability by utilizing high-strength monofilament materials, precise weaving techniques, and specialized surface treatment technologies. Their independently developed ultra-high-pressure belt filter machine belts effectively reduce sludge moisture content, promoting sludge volume reduction and energy-saving applications, thereby supporting the green and efficient development of the municipal wastewater treatment industry.

11

2025

/

10

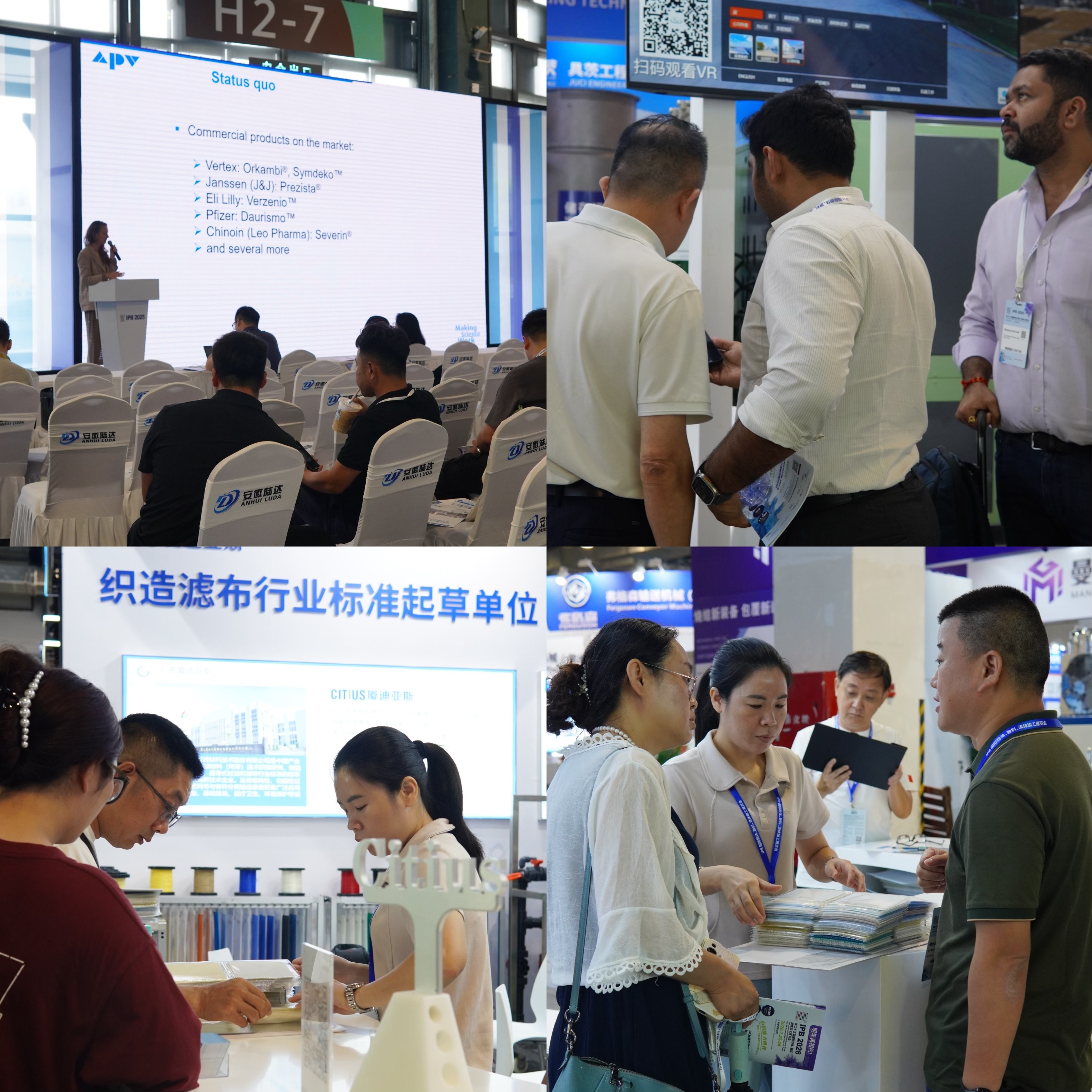

China's Nano-Micron Powder Filter Press Technology to Be Showcased at IPB 2025

The future of industrial filtration is focused on precision and sustainability, two areas where CITIUS is a clear leader. As a national high-tech enterprise and an industry standard-drafting unit, CITIUS is dedicated to continuous research and development. The company’s presence at IPB 2025 underscores its commitment to collaborating with global partners to address the most complex filtration challenges.

10

2025

/

10