Xiamen Xiadias has been invited to attend the 2025 National Forum on Innovation and Development of Nanometer Metal Powder/Slurry Preparation and Applications.

Release time:

2025-09-28

——New-generation nanomicro-powder filtration machine sets a new trend in solid-liquid separation

On September 25–26, 2025, the "National Forum on Innovation and Development of Nanomaterial Metal Powders/Slurries: Preparation and Applications" officially kicked off at the Holiday Inn Suzhou Huirong Plaza. The forum brought together industry leaders from across China—companies specializing in the production and downstream applications of nanomaterial metal powders/slurries, suppliers of nanomaterial production equipment, providers of testing and safety protection devices, as well as renowned experts and scholars from research institutions and universities—to jointly explore the promising future applications and groundbreaking technological advancements of nanomaterial metals in emerging industries.

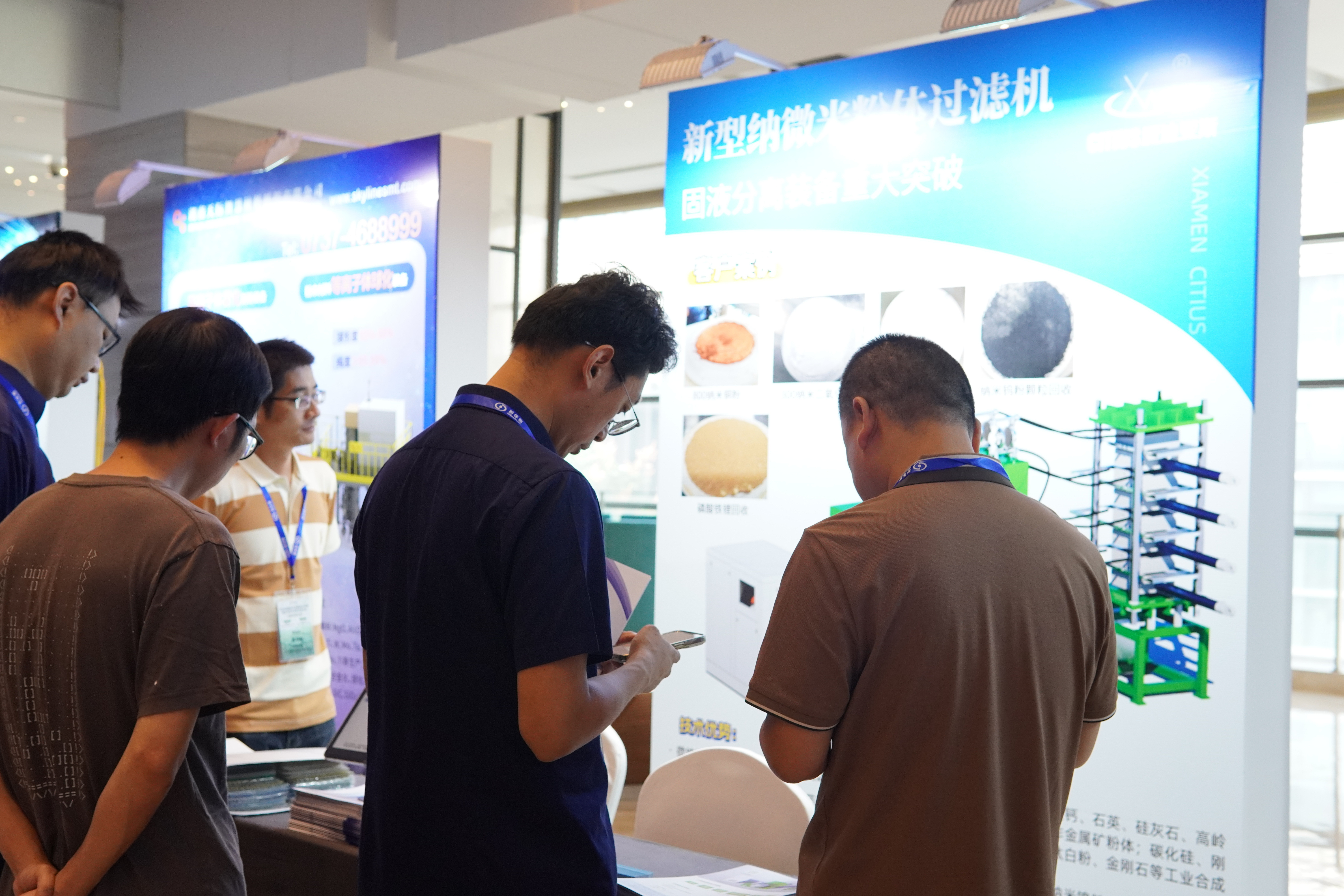

Photos from the conference venue

As a national-level high-tech enterprise that has been deeply rooted in the fields of industrial filtration materials and solid-liquid separation equipment for more than three decades, Xiamen Xedia Filter Materials Technology Co., Ltd. Invited to attend the conference, we highlighted the latest R&D developments. New-Type Nanometer-Micrometer Powder Filtration Machine , bringing a cutting-edge exploration into the industry on "efficient and pure filtration."

Industry Background: The Era of Opportunities for Nanometal Powders and Pastes

In recent years, with the rapid development of industries such as new energy, semiconductors, electronic ceramics, and aerospace, the demand for nanometal powders and slurries has experienced explosive growth. Their unique High specific surface area and high reactivity , endowing the material with tremendous potential in catalytic, conductive, thermal, magnetic, and optical properties.

However, the preparation of High sphericity, excellent dispersibility, high purity, and low oxygen content Nanopowders and slurries, however, represent one of the biggest challenges facing the entire industry chain. Particularly in the scale-up production phase, issues such as insufficient slurry purity, particle agglomeration, and substandard filtration retention rates often become critical bottlenecks that hinder industrial upgrading.

Against this backdrop, how can we achieve Stable and Controllable Nanometer- to Micrometer-Scale Filtration and Separation , becoming a core issue that urgently needs to be addressed within the industry.

|

|

|

|

Photos from the conference venue

Pain Point Analysis: Limitations of Traditional Filtration Processes

Currently, the filtration methods commonly used in the industry include traditional pressure filters, bag-type centrifugal filters, membrane filtration, and more—but these approaches clearly fall short when handling nanoscale slurries.

Insufficient precision : Conventional filtration precision often fails to capture particles as small as tens of nanometers or even sub-micron levels.

Low retention rate : Some key powder particles are difficult to completely separate, leading to a decrease in slurry purity.

Flux and efficiency are limited. : High precision often means slower filtration speeds, making it difficult to ensure production efficiency.

Easily clogged, difficult to clean : During prolonged operation, the equipment frequently clogs, leading to high maintenance costs.

For high-end application scenarios such as electronic pastes and semiconductor pastes, these pain points directly affect material performance and the effectiveness of downstream applications.

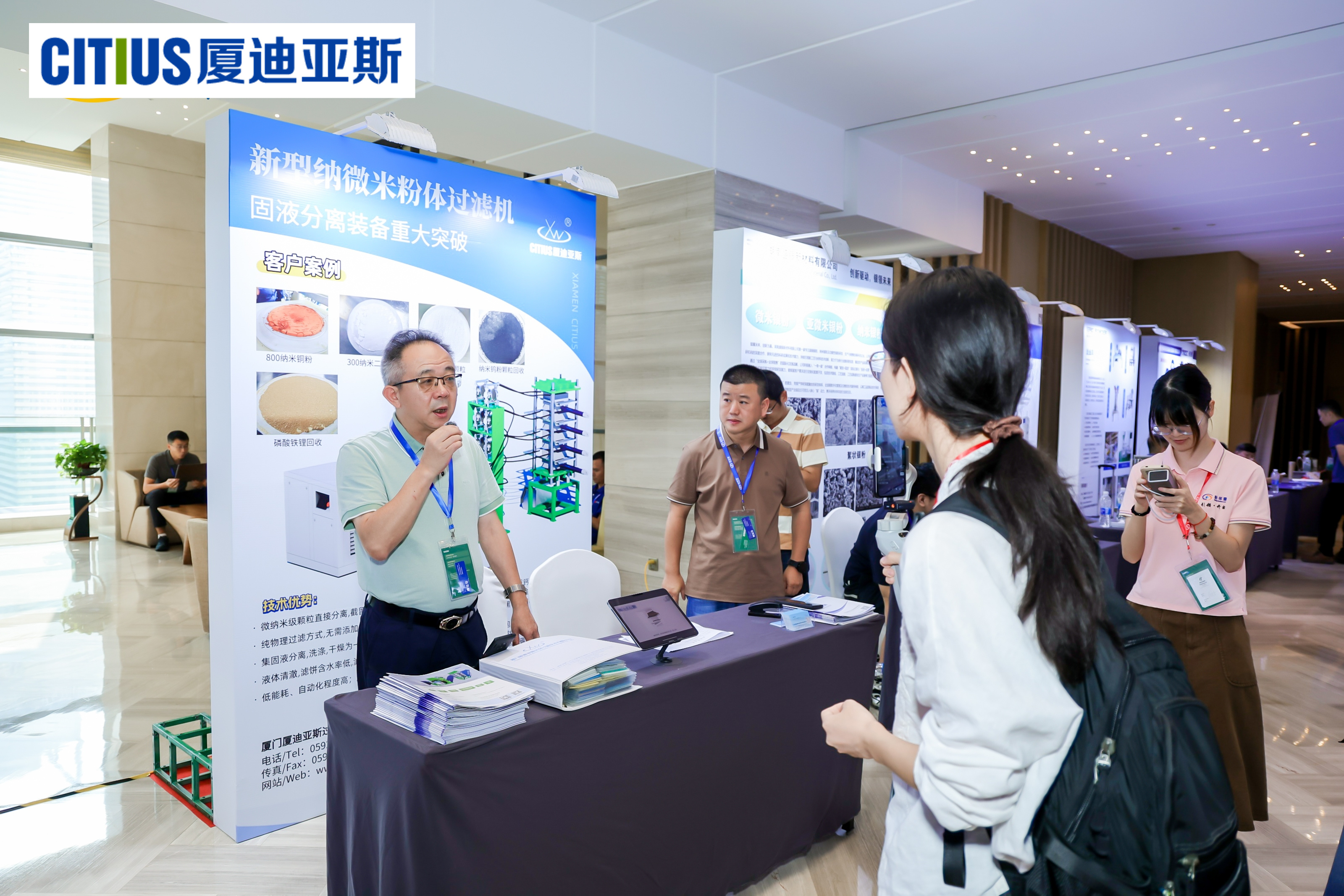

Mr. Guan Taiping, Chairman of Xadias, Accepts Media Interview

Xadia Solution: A New Nano-Micro Powder Filtration Machine

Addressing industry pain points, Xadias has launched New-Type Nanometer-Micrometer Powder Filtration Machine This is an innovative piece of equipment developed specifically to address the challenging task of nano- and micro-particle slurry separation. With its focus on high precision, stability, and industry compatibility, it empowers companies to achieve truly efficient and pure separation processes.

Core Advantages

1. Direct separation of nanometer- and micrometer-sized particles

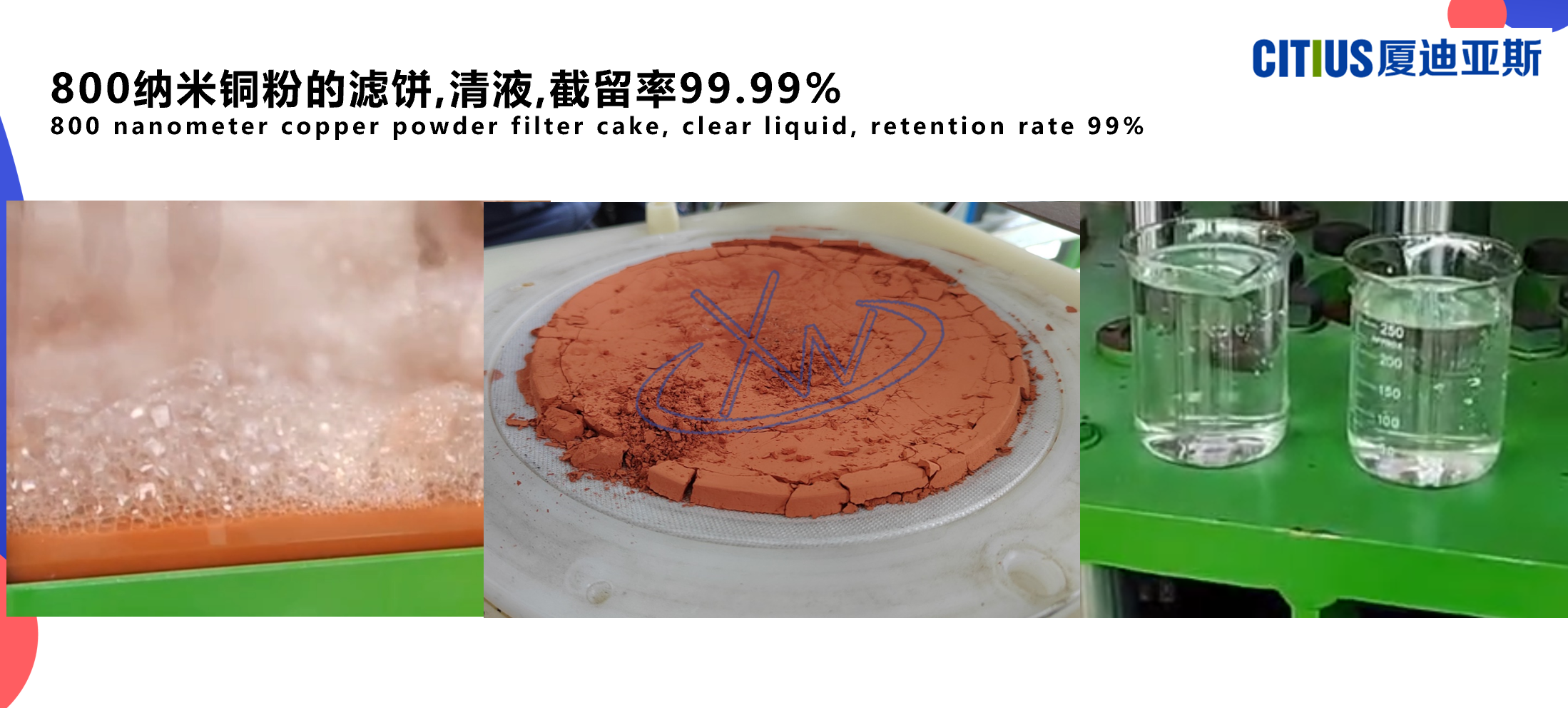

It can achieve high-precision separation of particles 25 nanometers and larger. The retention rate is as high as 99.99%. , meeting the stringent purity requirements for electronic pastes, semiconductor powders, and more.

2. Purely physical filtration method

Utilizing purely physical filtration, it eliminates the need for adding any additional chemicals or additives, thereby preventing secondary pollution while ensuring that the properties of the pulp remain unchanged.

3. Compatible with Multiple Types of Nanopowders/Slurries

This is the device's biggest highlight. Whether it's metal-based powders (such as silver powder, copper powder, nickel powder, zinc powder, aluminum powder, iron powder, zirconium powder, titanium powder, and more) or oxide powders (including nickel oxide, zinc oxide, alumina, iron oxide, titanium oxide, silicon oxide, calcium carbonate, silicon carbide, and others), it even encompasses materials commonly used in the semiconductor industry. Silver paste, conductive paste , the equipment ensures stable compatibility. Not only does it maintain the stability of the separation process, but it also enhances the electrical conductivity of the metal powder, resulting in a product with even superior performance.

4. Integrates multiple functions into one

Achieve Solid-liquid separation, washing, drying The three major processes are integrated, ultimately yielding Liquid clarification, low moisture content in the filter cake, and easy cake detachment The ideal effect.

5. Low Energy Consumption and Automation

The equipment features low energy consumption, a high degree of automation, and supports continuous operation, significantly reducing operational costs while boosting the overall efficiency of the production line.

Customer Application Cases

Application Areas

Nanomicro Powder Material Nanometer-sized copper powder, nickel powder, silver powder, zinc powder, aluminum powder, iron powder, zirconium powder, titanium powder, and other metallic powders, as well as inorganic powders such as nickel oxide, zinc oxide, alumina, iron oxide, titanium oxide, silicon oxide, calcium carbonate, and silicon carbide.

Industrial Powder Raw Materials Non-metallic mineral powders such as talc, heavy calcium carbonate, quartz, wollastonite, kaolin, mica, and graphite, as well as industrially synthesized powders including silicon carbide, corundum, silicon nitride, precipitated silica, titanium dioxide, and diamond.

Wastewater Treatment : For industrial wastewater containing nanometer-scale pigments, it can achieve efficient filtration and purification, fulfilling the dual objectives of environmental protection and resource recovery.

Customer Application Cases

On-site Response: Industry’s Attention and Expectations

At the forum exhibition site, Xadias' newly launched nanomicro-powder filtration machine drew attention from companies in fields such as electronic pastes, next-generation energy batteries, and semiconductors.

Many representatives from participating companies stated that they are currently facing challenges in the process of nanomaterial powder preparation. Slurry impurities are difficult to remove, and batch-to-batch stability is insufficient. The issue, while Xadias' solution is expected to help it significantly improve product quality and enhance its competitiveness.

An industry expert remarked during the discussion: "In the next 5 to 10 years, nano-metal pastes will become a critical strategic material for both the electronics and energy industries, and breakthroughs in the filtration process will directly determine the success or failure of upstream preparation and downstream applications."

|

|

|

|

Photos from the conference venue

Future Outlook: Empowering the Upgrade of the Nanopowder Industry

Xiadis deeply understands that the application of nano-metal powders and slurries is not only an emerging market but also a strategic cornerstone for driving the advancement of advanced manufacturing. Moving forward, the company will continue to ramp up its R&D investments, focusing on High-efficiency filtration, intelligent control, and industrial-scale adaptability Three key directions will drive the technological iteration and market implementation of the new nanomicro-powder filtration system.

Meanwhile, Xadias will collaborate with upstream and downstream partners to jointly explore more application scenarios for nanomaterial powders in fields such as electronics, photovoltaics, semiconductors, new energy, and biomedicine, helping the industry make a leap from "material breakthroughs" to "industrial upgrades."

Group photo from the conference

Conclusion

In Suzhou's golden autumn month of September, the forum venue was not only a deep dialogue between technology and industry, but also a forward-thinking exploration of future materials innovation.

Xiamen Xadias With 30 years of expertise in solid-liquid separation and a commitment to continuous innovation through R&D, we are driving the next generation of filtration equipment to the forefront of industry. The new nanometer-scale micronized powder filter machine is not just a piece of equipment—it is the key engine propelling high-quality development for nano-metal powders and slurries.

📌 About Xiamen Xiadias

Xiamen Xedia Filter Materials Technology Co., Ltd., established in 2009, is a national-level high-tech enterprise and the drafting unit of industry standards for filter belts used in belt filter machines. The company specializes in the research, development, and manufacturing of filtration materials and solid-liquid separation equipment, with its products exported worldwide. It provides comprehensive filtration solutions tailored to industries such as chemical engineering, metallurgy, mining, new materials, and environmental protection.