Nano-Micron Powder Filter for Battery Cathode Nano SrCO₃ Production

Release time:

2025-07-11

Application of a new type of nano-micrometer powder filter in the production of nano-strontium carbonate particles for battery cathode materials

With the continuous breakthroughs in new energy battery material technology today, each refinement of material particle size is an ultimate challenge to the precision and stability of manufacturing equipment. Especially in the field of lithium-ion batteries and new solid-state batteries, the microstructure of the cathode material directly determines its capacity, rate performance, and cycle life.

Strontium carbonate ( SrCO ₃ ), a cathode material additive that has gradually emerged in recent years, plays a key role in improving ion migration efficiency and structural stability in high-nickel ternary and lithium-rich manganese-based cathode materials due to its excellent thermal stability and conductivity control capabilities. As the material particle size advances from the micrometer level to the nanometer level and even sub-nanometer level, the fine filtration and classification process of nano-strontium carbonate particles has become an indispensable part of the manufacturing of high-performance battery materials.

Xiamen Xiadias Filtration Materials Technology Co., Ltd., relying on 30 years of experience in the field of filtration and separation, has launched a new type of nano-micrometer powder filter, which is specifically designed to address this industry-level problem. In this article, we will systematically analyze the application characteristics and preparation challenges of nano-strontium carbonate particles, and in-depth discuss the unique value and technical solutions of Xiadias nano-micrometer powder filter in this process.

I. Industrial Value and Application Trend of Nano-Strontium Carbonate Particles

Strontium carbonate has traditionally been used in optoelectronic glass, magnetic materials, and the ceramics industry. In recent years, with the evolution of battery cathode material systems, its application in high-performance lithium batteries has gradually expanded, especially showing significant value in the following aspects:

- Crystal structure stabilizer Introducing strontium carbonate into high-voltage ternary materials can improve the oxygen stability of the material, delay phase transition, and enhance cycle stability.

- Conductivity regulator Nano-strontium carbonate particles can be uniformly coated or doped on the surface of cathode particles to improve the overall electron conduction network of the electrode.

- Enhanced high-temperature safety Strontium carbonate has a good absorption and conduction effect on thermal stress, which helps to improve the thermal stability and safety factor of the battery.

Currently, many domestic and foreign power and energy storage battery manufacturers have tried using nano SrCO ₃ for doping or coating, and its particle size requirements are concentrated in 50~300 nanometers , and extremely high standards are set for the uniformity of particle size distribution, agglomeration control, and purity.

II. Filtration Challenges in the Preparation of Nano-Strontium Carbonate Particles

In the preparation process of nano-powders, filtration is one of the most challenging processes. For nano-strontium carbonate, coprecipitation or high-temperature liquid-phase reaction synthesis is usually used, and the post-treatment process involves the separation of a large amount of mother liquor, the recovery of particles, and the classification process. There are several difficulties in this process:

- Severe particle agglomeration

Nanoparticles have high surface energy and are very easy to form agglomerates in a wet state. Traditional filtration processes cannot effectively disperse and separate them. - Extremely high filtration accuracy requirements

The target particle size is in the hundreds of nanometers or even smaller, and traditional bag filtration or filter presses are difficult to achieve a stable cut point. - Low particle recovery rate

Nanoparticles are easily lost with the filtrate, resulting in large product loss, low yield, and seriously affecting economic efficiency. - Easy to clog filter cloth / filter membrane

Particles that are too small are very easy to cause filter layer clogging. Traditional equipment has short filtration cycles and frequent cleaning, affecting the continuity of the production line.

Therefore, equipment that truly adapts to the nano-strontium carbonate filtration process must not only have submicron filtration accuracy , but also achieve control of agglomerated particle separation and high-efficiency recycling 。

III. 25 Nanometer Separation Capability: Core Technical Advantages of Xiadias Nano-Micrometer Powder Filter

Faced with the dual challenges of high-precision separation and green manufacturing, the new nano-micrometer powder filter developed by Xiadias has 25 nanometer filtration capability , which can be stably applied to the classification, purification, and clear liquid treatment of various key processes of nanometer powder materials. It is one of the first advanced equipment in China to achieve industrial and continuous operation.

Its core technical advantages are as follows:

1. Direct interception of micro-nano particles, filtration accuracy breaks through the technical ceiling

Through a high-precision nano-level filter belt system and independent fluid channel control technology, the equipment can effectively classify powders in the range of 25~500 nanometer particle size , with a retention rate as high as 99.9% or more 。

2. Pure physical filtration, no need to add any auxiliaries or chemical precipitants

The equipment uses a pure physical filtration mechanism , which does not rely on chemical agents, flocculants, or additives during the entire process, avoiding secondary pollution and ensuring the purity and structural integrity of the powder.

3. Three effects in one machine: integrating solid-liquid separation, washing, and drying

Achievable Online cleaning liquid — Filter cake washing — Filter cake pre-drying Integrated process. High washing efficiency, filtrate clarity superior to 99% ,low filter cake moisture content, good stripping properties, beneficial for subsequent processing.

4. Energy saving and consumption reduction, strong economic operation

Using Low vacuum negative pressure system and Intelligent variable frequency control system ,energy consumption is reduced by about 30% ,supports 24 hours of automatic operation, low maintenance cost.

IV. Typical applicable materials: Widely covers industrial powders and micro-nano materials

Xiadiya Sna Micrometer Powder Filter has strong adaptability and is widely used in industrial powder raw materials, micro-nano functional materials, and particulate waste liquids.

1. Industrial powder raw materials

- Non-metallic mineral powders :Talc, heavy calcium, quartz, wollastonite, kaolin, mica, graphite, etc.;

- Industrial synthetic powders :Silicon carbide, brown corundum, silicon nitride, fumed silica, titanium dioxide, diamond, etc.

Application industries cover coatings, ceramics, plastics, rubber, batteries, flame retardants, precision casting, etc.

2. Micro-nano powder materials

- Metal powders :Nano nickel powder, silver powder, zinc powder, aluminum powder, iron powder, zirconium powder, titanium powder;

- Oxide powders :Nickel oxide, zinc oxide, aluminum oxide, iron oxide, calcium carbonate, titanium dioxide, silicon dioxide;

- Non-oxide type :Silicon carbide, aluminum nitride, silicon nitride, tungsten carbide, etc.

Suitable for electronic materials, functional ceramics, energy materials, catalysts and other high-end manufacturing.

3. Micro-nano pigment and functional waste liquid treatment

- Containing in the battery manufacturing process Li 、 Ni 、 Co Nano oxide waste liquid;

- Recovery of color paste pigment intermediate liquid, such as iron oxide red, zinc oxide blue;

- Intermediate liquid filtration for high-end cosmetics and coating additives;

- Efficient recovery of precious metal particles in waste liquid in the precision electronics industry.

Equipment support Closed-loop reuse of high-concentration waste liquid ,to help enterprises achieve green and low-carbon development.

V. Case studies: A win-win path to improve efficiency and quality

In the strontium carbonate nanoparticle project of a certain new energy material manufacturing enterprise, Xiadiya Sna micrometer filter is used as a key process equipment, achieving the following results:

- The original process used a traditional plate-and-frame filter press, with a particle loss rate of 15% ,poor washing effect;

- After replacing Xiadiya equipment, the particle recovery rate increased to 99.2% ,the filter cake moisture content decreased to 17% 以下 ;

- Achieve Automatic operation and remote monitoring functions ,significantly reducing labor costs and equipment downtime;

- Product particle size control standard deviation reduced 30% ,the qualified rate of finished products exceeds 98.8% 。

This project verified the adaptability of the new filtration equipment to High-end nanomaterial refining process ,providing a replicable process template for subsequent nanomaterial enterprises.

VI. Conclusion: Future materials, future equipment

Micro-nano powder filtration technology is moving from traditional chemical industry to the core of cutting-edge industries such as new energy, new materials, and biomedicine. The equipment technology behind it is no longer a simple “ Filter cloth + Structure ” ,but a complex system integrating physical field control, nano-interface regulation and automation system.

Xiamen Xiadiya, with “ Specialized and new ” as the development goal, based on 30 years of experience in the manufacturing of filter materials and equipment, is becoming a leader in micro-nano separation technology.

In the future, we will continue to focus on the following areas:

- Research and development of nano-scale multifunctional filter materials;

- High-throughput intelligent module integration;

- Customer-customized solutions and process optimization services;

- Green manufacturing and circular economy support system.

In this “ Material is king ” In this new era, only equipment providers who truly understand materials and separation can stand at the high end of the industrial chain. Xiadias is committed to contributing professional strength to the clean preparation and efficient separation of global high-performance materials.

Slurry and filtrate of nano strontium carbonate particles used as raw materials for battery cathode materials

Filter cake of nano strontium carbonate particles used as raw materials for battery cathode materials

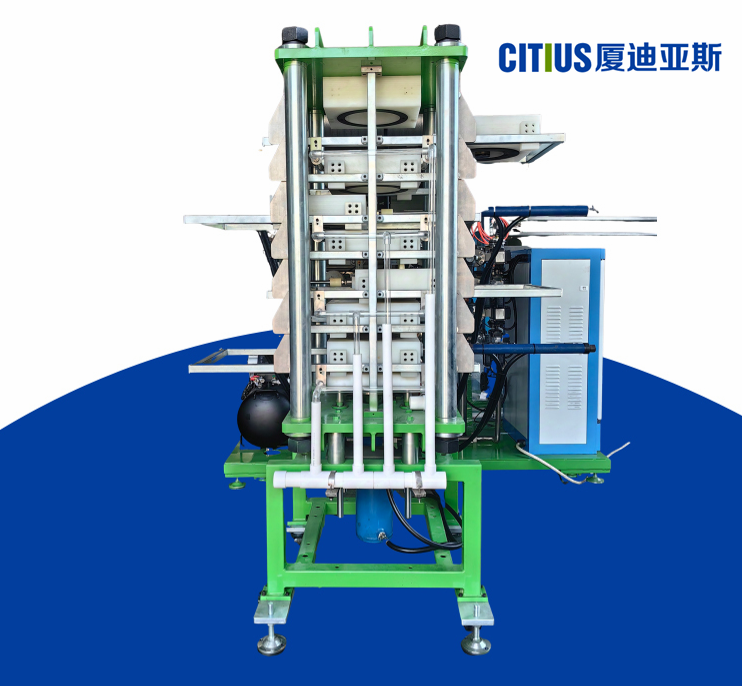

New type of nano/micro powder filter

Previous article: