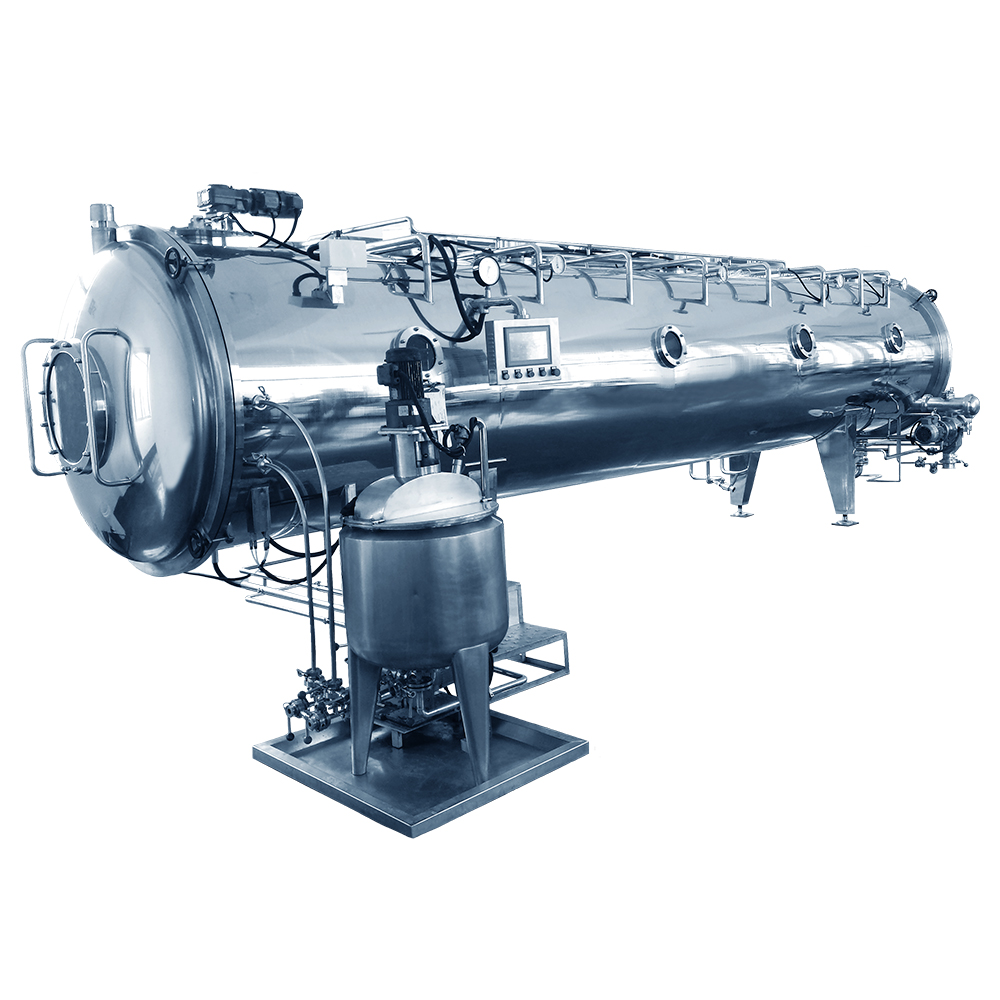

Vacuum Belt Dryer for Continuous Solid Drying

Release time:

2025-06-30

In today’s fast-evolving industrial landscape, efficient, reliable, and scalable drying technologies are essential across numerous sectors — from pharmaceuticals and chemicals to food processing and battery materials. One standout solution meeting the demands of continuous, low-temperature drying for heat-sensitive solids is the vacuum belt dryer (VBD). When combined with high-temperature drying mesh belts, this technology offers unmatched performance in preserving product quality while maximizing throughput.

What Is a Vacuum Belt Dryer?

A vacuum belt dryer is an advanced drying system designed for continuous, low-temperature drying of pastes, suspensions, slurries, and fine solids. Unlike conventional hot-air drying equipment, a vacuum belt dryer operates under a vacuum environment, significantly lowering the boiling point of moisture. This allows materials to dry gently at lower temperatures — often below 80°C — preserving heat-sensitive components such as active pharmaceutical ingredients, enzymes, food nutrients, and specialty chemicals.

Key components of a vacuum belt dryer system include:

- Vacuum chamber: Maintains negative pressure to enable low-temperature evaporation.

- Conveyor mesh belt: Transports the material steadily through drying zones.

- Heating zones: Typically equipped with hot water, steam, or electric heaters for precise thermal control.

- Condensation unit: Captures evaporated moisture, ensuring closed-loop drying.

- Discharge system: Collects dried product, often in flake or powder form.

The Role of Drying Mesh Belts in Vacuum Belt Dryers

The mesh belt — often made from high-strength, heat-resistant materials — is the backbone of a vacuum belt dryer. It determines how the product moves, dries, and separates from the system. Depending on the drying application, the mesh belt must offer:

- Thermal stability: Resistance to constant exposure to heat.

- Chemical resistance: Compatibility with acidic, alkaline, or solvent-based materials.

- Air permeability: Proper open area for vapor release and efficient drying.

- Mechanical strength: Durability under load and tension.

High-Performance Mesh Belts: PET, PPS, and PTFE Options

Citius and other leading manufacturers offer a variety of drying mesh belts engineered for vacuum and thermal drying systems. Materials commonly used include:

- PET (Polyester): Suitable for temperatures up to 150°C. Good mechanical strength and affordable, often used in food and wastewater applications.

- PPS (Polyphenylene sulfide): Withstands temperatures up to 190°C and offers excellent chemical resistance. Ideal for drying high-performance materials and specialty chemicals.

- PTFE (Polytetrafluoroethylene): Also known as Teflon mesh, this material offers exceptional temperature resistance (up to 260°C), non-stick surface, and chemical inertness — a top choice for lithium battery slurries, biotech drying, and sticky materials.

Each of these belts can be tailored in terms of:

- Weaving structure (plain, twill, leno)

- Mesh size and open area

- Surface treatment (coating, calendaring)

- Edge reinforcements and sealing

Advantages of Vacuum Belt Drying

1. Low-Temperature Drying

Vacuum environments allow evaporation to occur at much lower temperatures than atmospheric drying. This is essential for:

- Pharmaceuticals

- Biological materials

- Fine chemicals

- Battery-grade powders

2. Continuous Operation

Unlike batch dryers, VBDs are fully continuous, allowing for scalable, automated production lines. This reduces labor, increases throughput, and improves consistency.

3. Gentle Material Handling

The belt gently carries material through drying zones without vigorous agitation. This ensures:

- Low dust generation

- Uniform product structure

- Minimal attrition or particle damage

4. Energy Efficiency

By recycling latent heat and operating in closed-loop systems, VBDs consume less energy per kilogram of dried material compared to traditional dryers.

5. Adaptability Across Industries

Industry | Application Example |

|---|---|

Food | Drying of fruit pastes, extracts, enzymes |

Pharmaceutical | Herbal medicine extracts, probiotics |

Battery | Drying of lithium iron phosphate (LFP) slurries |

Chemical | Pigments, dyes, polymers, resins |

Biotech | Protein solutions, bio-based materials |

Extra-Wide Configurations for High-Capacity Needs

Industrial-scale applications often demand extra-wide dryer configurations, ranging from 1.5 meters to over 3 meters in belt width. These systems are engineered to:

- Handle high-viscosity pastes and slurries

- Achieve high drying capacity (up to several tons/day)

- Integrate with upstream mixing and downstream milling or packaging lines

With modular zones and multi-stage drying capabilities, large-scale vacuum belt dryers offer a compact footprint with high drying efficiency.

Mesh Belt Design Considerations for Performance

When choosing a drying mesh belt for your vacuum dryer, consider:

- Open area: More open area = better vapor flow, but too much can cause product loss.

- Tension resistance: For long belts, tension must be uniform to prevent slippage.

- Anti-stick properties: Teflon coatings or PTFE belts reduce product buildup.

- Cleanability: Belts should support in-place cleaning (CIP) to prevent contamination.

Why Choose Vacuum Belt Drying Over Other Methods?

Technology | Vacuum Belt Dryer | Spray Dryer | Tray Dryer | Rotary Dryer |

|---|---|---|---|---|

Temp Control | Excellent | Moderate | Poor | Poor |

Continuous Process | Yes | Yes | No | Yes |

Product Recovery | High | Medium | High | Low |

Energy Efficiency | High | Low | Medium | Low |

Ideal For | Heat-sensitive | Fine liquids | Powders | Bulk solids |

For operations seeking high-value product yield, minimal thermal degradation, and streamlined automation, vacuum belt drying is often the best-fit solution.

Conclusion

Vacuum belt dryers, when paired with the right high-temperature drying mesh belts, offer a powerful combination of efficiency, gentleness, and industrial scalability. Whether you're drying delicate herbal extracts, advanced chemical slurries, or moisture-sensitive food pastes, this technology provides a flexible, continuous, and clean drying solution.

If your process demands precise temperature control, consistent drying quality, and low energy consumption, it’s time to invest in next-generation vacuum belt drying technology — supported by engineered mesh belts built to endure heat, stress, and time.

For more details on customized drying belts or industrial vacuum dryer configurations, contact us today. Let us help you build a smarter, cleaner, and more efficient drying system.