Application Research of Nanometer Filtration Technology in the Precision Preparation of Electronic Slurries and Semiconductor Materials

Release time:

2025-05-23

Application Research of Nanometer Filtration Technology in the Precision Preparation of Electronic Slurries and Semiconductor Materials

—— Taking Silver Paste Filter and New Type of Nano-Micro Powder Filter as Examples

Introduction

With the continuous upgrading of the electronic information industry and the evolution of semiconductor manufacturing technology, electronic slurries (such as silver paste, copper paste, and aluminum paste) play a crucial role in integrated circuit packaging, photovoltaic cells, touch screens, LTCC (Low Temperature Co-fired Ceramic) and other fields. The requirements for the uniformity, purity, stability, and dispersibility of these high-end slurries are constantly increasing. Especially in the context of the miniaturization and high-density development of devices, the complete removal of micron-level and submicron-level impurities in the slurry has become a key step in ensuring product yield.

Against this backdrop, filtration equipment, especially new nano-micro powder filters for nano-scale powder separation, is gradually becoming an important part of the core process. This article focuses on key equipment in electronic slurries —— Silver paste filters and new nano-micro powder filtration technology, combined with process pain points, in-depth discussion of their working principles, structural design, technological evolution and their profound impact on the industry chain.

I. Filtration Challenges in Electronic Slurry Preparation

Electronic slurry is a complex dispersion system composed of metal powders (such as Ag 、 Cu 、 Ni ), dispersants, organic solvents, and additives. In practical applications, slurry filtration faces the following challenges:

- Wide particle size distribution, making it difficult to effectively remove submicron impurities without losing effective components ;

- High-viscosity slurries are prone to clogging traditional membrane filters, easily causing a sharp increase in pressure difference and a decrease in filtration efficiency ;

- Some slurries are highly active and easily oxidized, requiring extremely high sealing and material compatibility during filtration ;

- Metal powders are expensive, excessive retention causes waste, and loss and material retention should be minimized 。

Therefore, traditional methods such as gravity sedimentation, bag filters, and ceramic filter plates cannot meet the increasingly stringent purification requirements of modern electronic slurries. New filtration equipment must achieve efficient removal of nano-micro impurities while preserving the activity and dispersibility of the slurry.

II. Challenges and Technological Breakthrough Directions in Silver Paste Filtration

Silver paste, as one of the most core and widely used functional materials in electronic slurries, its quality directly affects the conductivity, printing accuracy, and device life. However, in its preparation and dispersion process, filtration, as a key link, faces a series of challenges:

1. High purity requirements and the difficulty of separating nanoparticles

Currently, high-performance silver pastes mostly use submicron or nano-scale silver powder, which has a narrower particle size distribution and more regular morphology, but this also puts extremely high demands on filtration accuracy. Traditional filter cloths or membranes are difficult to balance high retention rate and high throughput, easily causing particle loss, blockage, or low filtration efficiency.

2. Influence of viscosity and dispersant system on the filtration process

Silver paste usually contains various surface modifiers, dispersants, and viscosity control agents. These organic additives are easily form stable flocculation structures under high shear conditions, increasing the filtration resistance. At the same time, the viscous slurry seriously pollutes the filtration medium, reducing its service life and increasing the maintenance frequency.

3. Filtrate recovery quality and slurry loss control

High-end silver paste is extremely valuable, and any filter cake residue or particle loss will cause direct raw material loss. Existing filtration methods often cannot achieve the dual guarantee of filtrate clarity and filter cake integrity, resulting in the need for secondary purification of the recycled liquid, increasing process complexity and operating costs.

4. Difficult to integrate washing and drying, reducing efficiency

Some high-end applications (such as crystalline silicon solar cell silver paste, conductive adhesive paste, etc.) are highly sensitive to silver powder surface residues, and additional washing or drying steps are required after filtration. However, conventional filtration processes are dispersed in multiple stages, resulting in a long process chain, low production efficiency, and hindering automation integration.

III. New Nano-Micro Powder Filter: A Major Breakthrough in Solid-Liquid Separation Equipment

In the precision preparation of electronic slurries and semiconductor slurries, separation equipment needs to not only achieve ultra-high precision, but also have multi-functional integration, low energy consumption, high efficiency and other modern industrial standards. The new nano-micro powder filter is a typical representative to meet this challenge, and its performance in micro-nano scale particle separation shows revolutionary performance:

- Direct separation of micro-nano particles, retention rate up to 99.9% : Electronic grade silver powder, nano copper powder, zinc oxide and other fine particles can be efficiently retained to avoid product scrap due to exceeding impurity particle size;

- Pure physical filtration method, no need to add any chemicals or auxiliaries : Avoid chemical interference, do not change the physical properties of the slurry system, and maximize the retention of the intrinsic properties of the powder;

- Conductivity rises to zero, material intrinsic properties perfectly preserved : No metal ions, conductive contaminants or leaching residues are released during the entire filtration cycle, ensuring the electronic purity and electrical continuity 。

- Integrates solid-liquid separation, washing, and drying, high overall efficiency : The treated liquid is clear and transparent, the filter cake has a low water content, and the stripping performance is good, effectively reducing slurry retention and waste;

- Low energy consumption, high degree of automation, extremely low operating cost : Especially suitable for large-scale, high-frequency production needs, it can be stably embedded in automated slurry production lines.

Based on the above advantages, this equipment has been widely regarded as an ideal solution for the processing of industrial powder raw materials, micro-nano powder materials, and wastewater containing micro-nano particles, and is applicable to the following material categories:

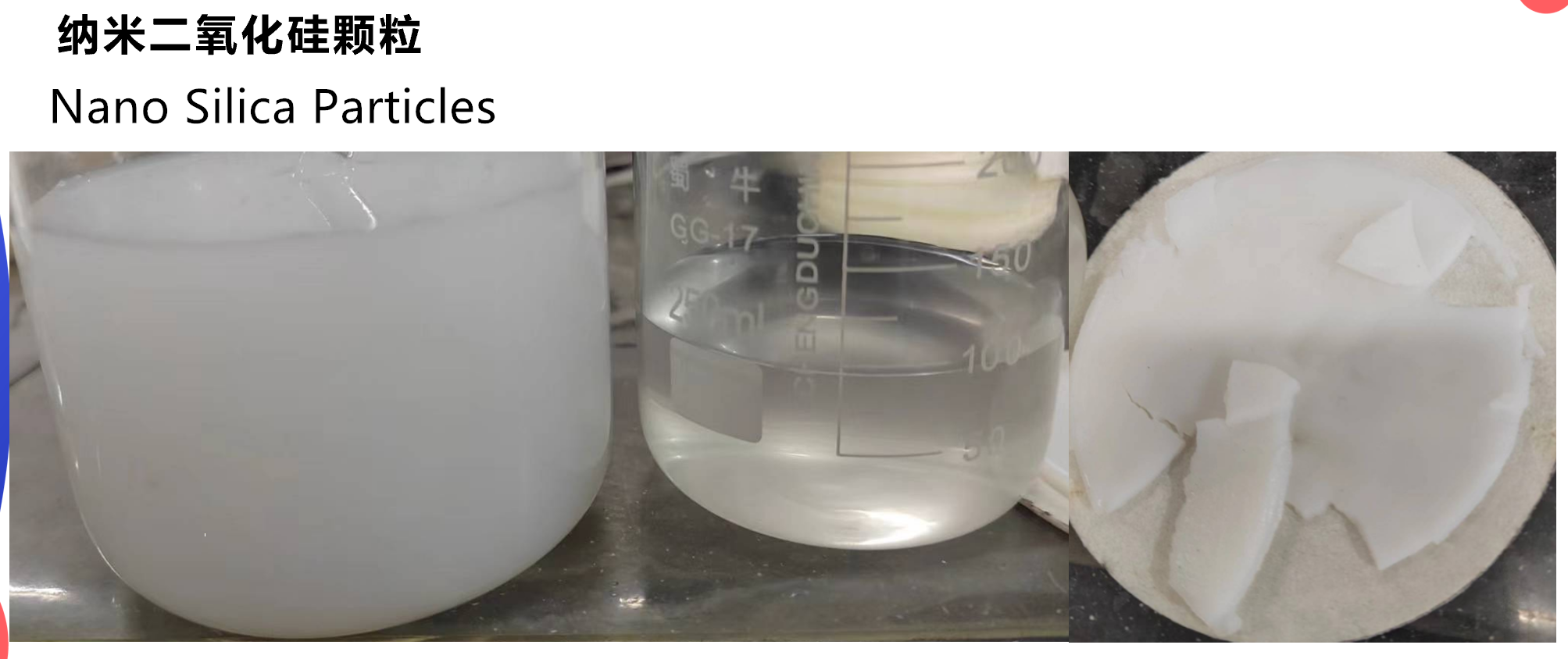

- Industrial powder raw materials :Talc, heavy calcium, quartz, wollastonite, kaolin, mica, graphite and other non-metallic mineral powders; silicon carbide, corundum, silicon nitride, fumed silica, titanium dioxide, diamond and other synthetic powders;

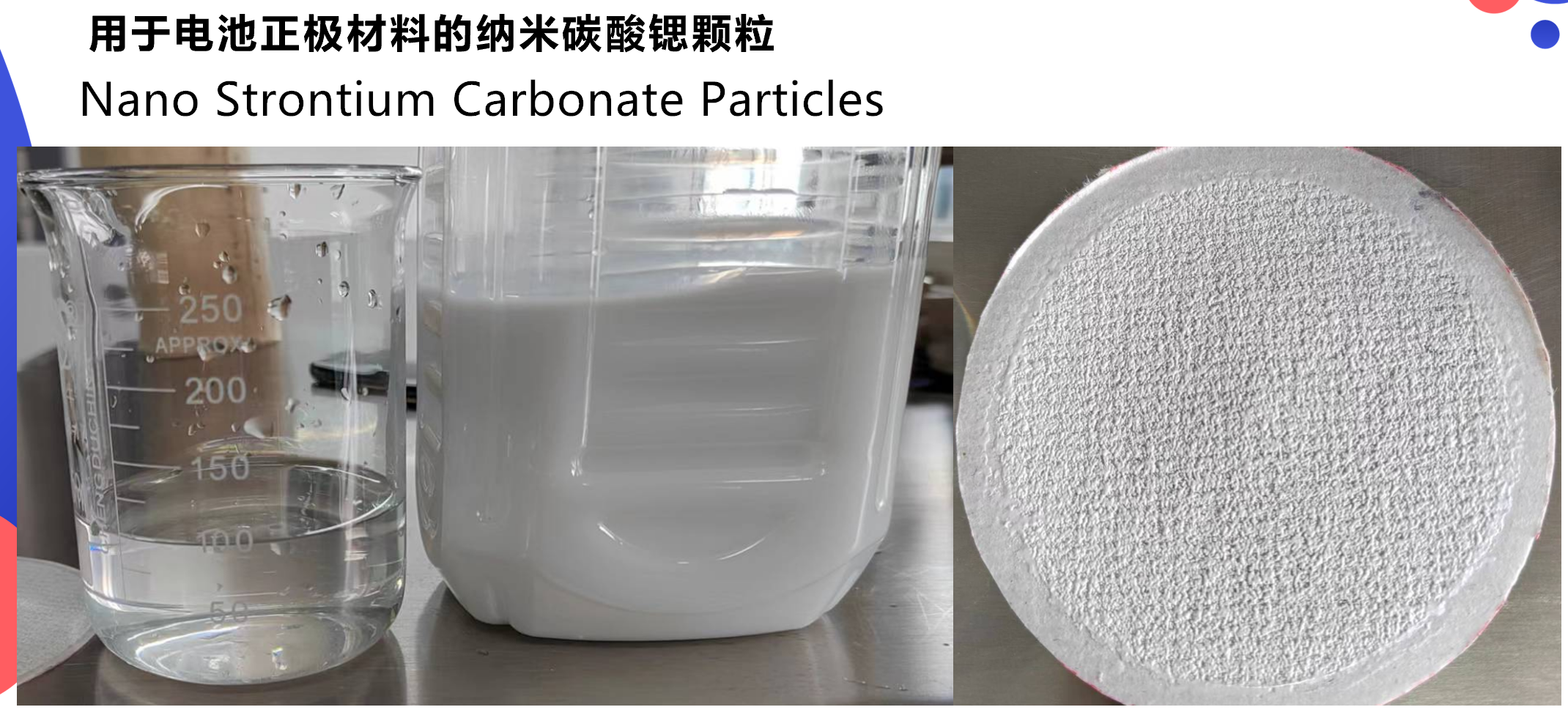

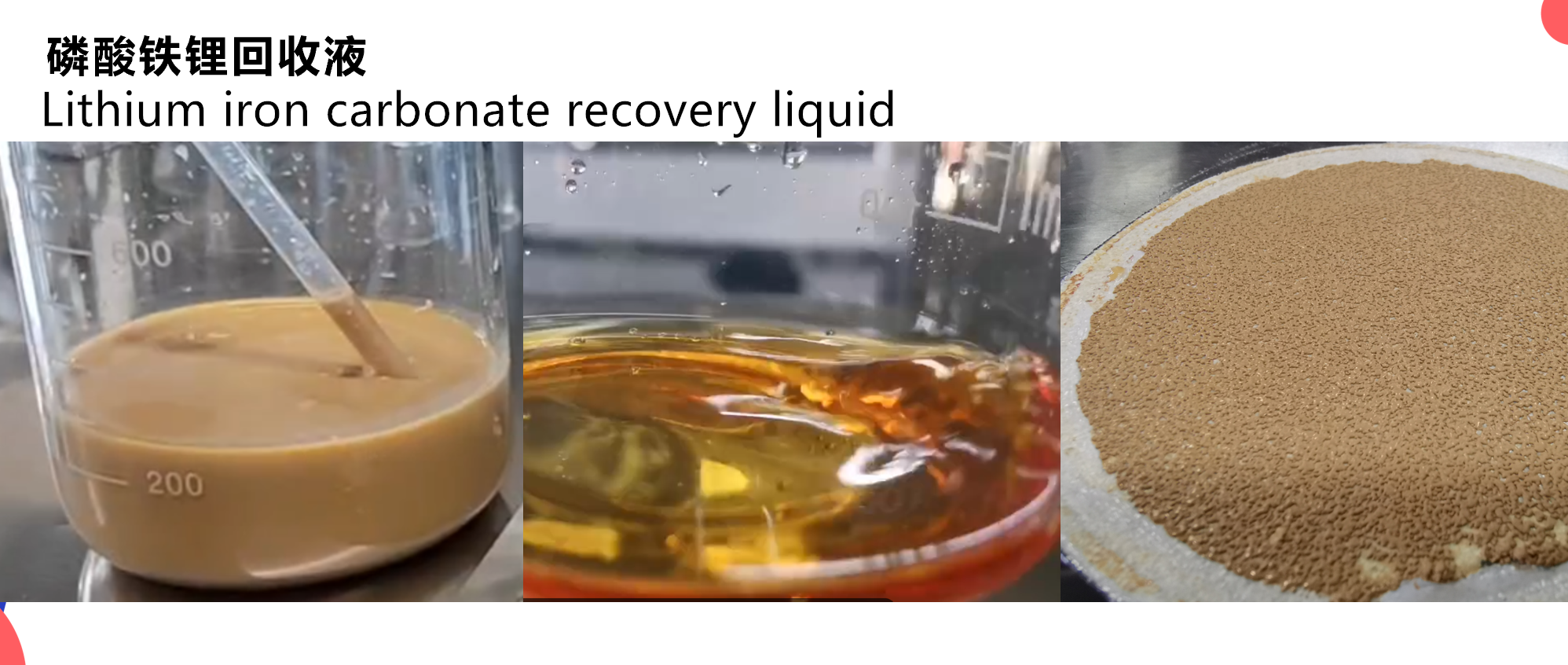

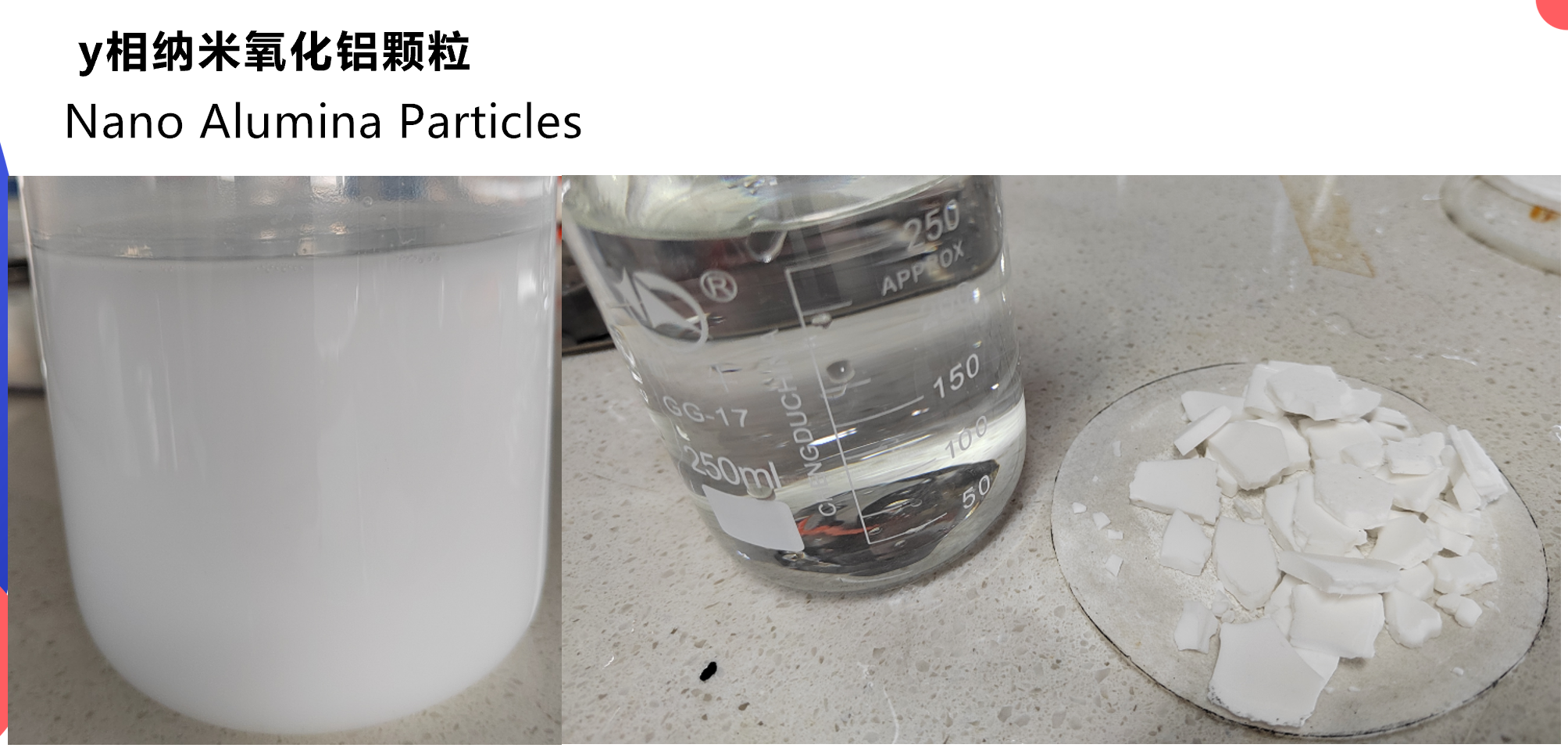

- Micro-nano powder materials :Nano silver powder, nickel powder, zinc powder, aluminum powder, iron powder, zirconium powder, titanium powder and their oxides such as nickel oxide, zinc oxide, aluminum oxide, iron oxide, titanium oxide, silicon oxide, silicon carbide, calcium carbonate, etc.;

- Electronic industrial wastewater treatment :It is particularly outstanding in high-precision purification processes for complex pollution systems containing pigments, organic impurities, and micro-nano particles.

Its technological concept has represented the development direction of high-end slurry filtration equipment, becoming one of the key process nodes in new material preparation lines.

IV. Conclusion

Electronic and semiconductor slurry “ High purity + High uniformity + High activity ” era, has presented unprecedented challenges and opportunities for filtration equipment. As the most representative high-end precision filtration equipment currently available, the new type of micro-nano powder filter has demonstrated excellent performance in the control of micron to submicron particles. In the future, as functional materials become increasingly complex and process boundaries continue to expand, filtration technology will continue to evolve towards intelligence, modularization, and system integration, helping the next generation of electronic materials achieve higher quality standards.

As a technological leader in the solid-liquid separation industry, Xiamen Xiadias Filtration Materials Technology Co., Ltd. has long been deeply involved in the field of industrial filter materials and filtration equipment. It not only participates in the formulation of national industry standards, but is also a system integrator of electronic slurry and semiconductor slurry filtration systems. Xiadias' new micro-nano powder filter has been implemented in key processes such as silver paste, copper paste, conductive oxides, and nano-powder purification, helping many domestic and foreign customers significantly improve product yield and production efficiency.