Filter belt solution in vacuum belt drying of traditional Chinese medicine extracts

Release time:

2025-09-10

1. Industry Background: Challenges in Modernizing Traditional Chinese Medicine and Solid-Liquid Separation

The traditional Chinese medicine (TCM) industry is at a critical stage of transformation and upgrading. From traditional decoction, concentration, and drying to modern extraction, concentration, and drying processes, the quality standards and production requirements of TCM preparations are continuously improving. TCM extracts, as the core intermediates of many Chinese patent medicines, directly affect the content, solubility, and stability of the active ingredients in the final preparations.

In the production of TCM extracts, the drying stage is crucial. Although traditional spray drying and vacuum drying are widely used, for TCM extracts with high sugar content and high viscosity, problems such as loss of heat-sensitive components, material sticking to walls, low drying efficiency, and high energy consumption often occur.

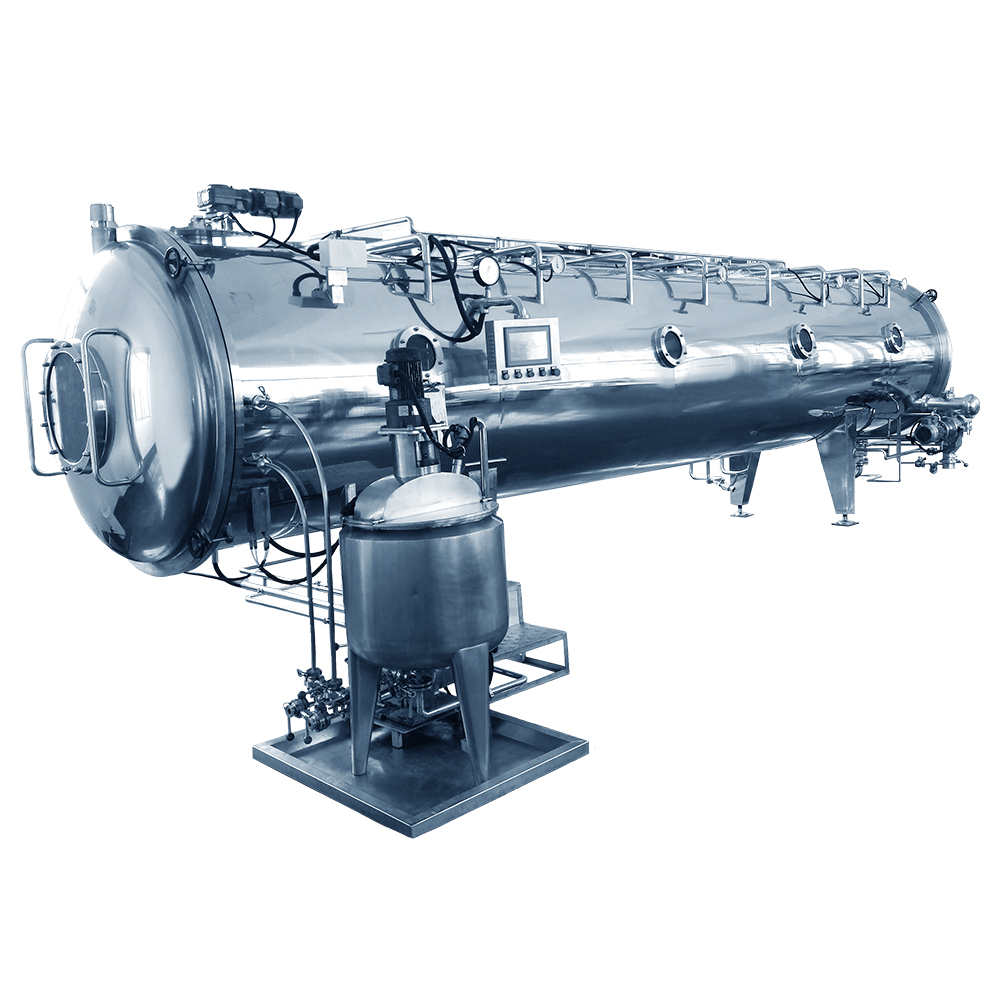

In recent years, vacuum belt dryers have gradually been recognized and promoted by the industry. Their core advantages include:

- drying under low-temperature vacuum conditions to effectively protect heat-sensitive components;

- continuous operation with high production efficiency;

- stable filter belt operation enabling automation from feeding, distribution, drying, cooling to discharging.

However, the stability of vacuum belt drying and the final product quality largely depend on a core component that is often overlooked — the filter belt. 。

2. The Role of the Filter Belt in Drying TCM Extracts

In vacuum belt dryers, the filter belt is not only the carrier for the material but also a key link in solid-liquid separation and transmission. It runs through the entire drying process and plays a decisive role in the quality of the TCM extract product.

The main functions of the filter belt are:

- Carrying function —to support fluid or semi-fluid TCM extracts, maintain uniform material distribution, and prevent material spillage and leakage.

- Filtering function —to block insufficiently dissolved or oversized particles during the initial material distribution stage, ensuring uniform drying.

- Transmission function —to move the material continuously within the vacuum chamber, achieving automated drying.

- Peeling function —to allow dried and formed extract blocks or sheets to detach smoothly, reducing sticking to the belt.

- Cleaning function —to maintain flatness, breathability, and cleanability during repeated operation, avoiding cross-contamination.

In other words, an excellent filter belt is an important guarantee for stable drying process operation and product consistency. 。

3. Common Pain Points in Drying TCM Extracts

In actual production, many companies encounter typical challenges when using vacuum belt dryers:

- Severe material adhesion

—extracts often have high sugar content and viscosity, making them prone to sticking to the belt surface after drying, causing peeling difficulties and even affecting subsequent material movement. - Filter belt breathability degradation

—after long-term operation, fine particles in the extract clog the filter belt micropores, reducing breathability, affecting vacuum stability and drying rate. - Filter belt deviation and unstable tension

—the filter belt runs a long distance inside the vacuum chamber; if tension control is poor, deviation easily occurs, affecting material uniformity and capacity. - Difficult cleaning and maintenance

—TCM extracts are mostly viscous substances with strong adhesion; inadequate cleaning leaves residues that affect the purity of the next batch. - Difficulty balancing capacity and energy efficiency

—an unsuitable filter belt results in either slow drying and low output or excessive energy consumption, making it hard to balance quality and cost.

These pain points determine that companies must have systematic solutions when selecting and optimizing filter belts.

4. Solutions: Optimization Ideas for Filter Belts in Vacuum Belt Drying

Considering the particularity of TCM extracts, solutions can be developed from the following aspects:

1. Anti-adhesion and easy peeling design

—special surface treatments on the filter belt can effectively reduce adhesion after drying, making the filter cake easy to detach, avoiding secondary breakage and yield loss.

2. Stable breathability and vacuum compatibility

—the filter belt must maintain uniform breathability to ensure balanced airflow distribution during drying, avoiding local incomplete drying or component degradation.

3. Precise tension and automatic deviation correction

—matching equipment and filter belt ensures uniform tension during long-term operation, preventing deviation or edge damage, improving overall machine stability.

4. Efficient cleaning and durability

—inside the vacuum chamber, the filter belt needs to adapt to CIP (clean-in-place) online cleaning or offline rinsing processes, facilitating quick production batch switching and ensuring pharmaceutical-grade cleanliness.

5. Customization and process synergy

Different types, concentrations, and viscosities of traditional Chinese medicine extracts require personalized filter belt designs. For example, highly concentrated extracts may opt for solutions focusing more on peelability, while extracts with more residue need enhanced filtration and breathability.

5. Application Cases: Typical Scenarios of Traditional Chinese Medicine Extracts

- Danshen and Astragalus Extracts

High sugar content and high viscosity, prone to adhesion after drying. Using filter belts with strong anti-adhesion and excellent peelability can significantly improve yield. - Licorice Extract

Contains a large amount of polysaccharides, and the material tends to foam under vacuum. Filter belts with uniform breathability help quickly release air, avoiding uneven drying. - Compound Traditional Chinese Medicine Extracts

Complex components and uneven particle distribution. Choosing filter belt solutions that balance filtration and transmission can improve batch-to-batch stability.

These cases demonstrate that the process requirements of different traditional Chinese medicines determine that filter belts need highly customized solutions. 。

6. Advantages and Practices of CITIUS

As a leading domestic company in filtration materials and solid-liquid separation equipment, Xiamen CITIUS Filtration Materials Technology Co., Ltd. CITIUS has accumulated rich experience in filter belt solutions for drying traditional Chinese medicine extracts.

Our advantages:

- Industry Experience :30 Years of research and manufacturing experience in industrial filtration materials, deeply understanding the pain points of solid-liquid separation in traditional Chinese medicine.

- R&D Strength Possesses an independent R&D center, capable of providing customized filter belt solutions tailored to different pharmaceutical process needs.

- Standard Setter As a drafting unit of industry standards for belt filter machine filter belts, product performance highly aligns with industry standards.

- Equipment Collaboration Not only provides filter belts but also develops supporting solid-liquid separation equipment to ensure overall system compatibility.

- Service Model Offers trial verification, process optimization, and online technical support to help customers reduce operational risks.

In practical applications, CITIUS's filter belts have been successfully applied in many traditional Chinese medicine companies, helping customers achieve:

- Improved peelability of filter cakes after drying 30% Above;

- dual optimization of increased output and reduced energy consumption;

- extended filter belt lifespan and reduced maintenance costs.

7. Future Trends: Green, Efficient, and Intelligent

The future development direction of the traditional Chinese medicine industry will inevitably combine green environmental protection and intelligent manufacturing. For vacuum belt drying, innovations in filter belts will also evolve in the following directions:

- Green and Environmentally Friendly More recycling and energy-saving designs to reduce energy consumption and waste.

- Intelligent Monitoring Using sensor technology to monitor filter belt tension, breathability, and lifespan to achieve predictive maintenance.

- Multifunctional Integration On the basis of filtration and transmission, integrating multiple functions such as anti-adhesion, cleanliness, and corrosion resistance.

This is not only a demand for equipment upgrades but also an inevitable requirement of modern pharmaceutical quality standards for traditional Chinese medicine.

8. Conclusion

Vacuum belt drying of traditional Chinese medicine extracts may seem like just " a step in the drying process, but in fact, it involves multiple considerations including efficacy preservation, capacity improvement, energy control, and quality stability. The filter belt, as a core component, plays a comprehensive role in bearing, filtering, transmitting, peeling, and cleaning. ” CITIUS

With over thirty years of industry accumulation and innovative R&D, provides systematic filter belt solutions for traditional Chinese medicine companies, enabling a stable, efficient, and green " drying process to truly take root. In the future, as the industry continuously raises requirements for drug quality and production efficiency, technological innovation in filter belts will continue to be an important driving force for the modernization of traditional Chinese medicine. ”In the future, as the industry's requirements for drug quality and production efficiency continue to increase, filter belt technology innovation will continue to be an important engine driving the modernization of traditional Chinese medicine.

Previous article:

The next one: