Building a Green Engine for Steel: Intelligent Application of Industrial Filter Cloth in the Treatment of Vanadium Iron Primary Slag Pulp

Release time:

2025-04-15

In “ dual carbon ” Against the backdrop of the continuously deepening "dual carbon" strategy and green manufacturing, the steel industry is accelerating the promotion of comprehensive resource utilization and environmental protection upgrades. In particular, the large amount of primary slag slurry generated during vanadium iron production, if not properly handled, will not only cause resource waste but may also lead to environmental hazards. Therefore, how to achieve efficient, environmentally friendly, and continuous solid-liquid separation of slag slurry has become a focus of attention within the industry.

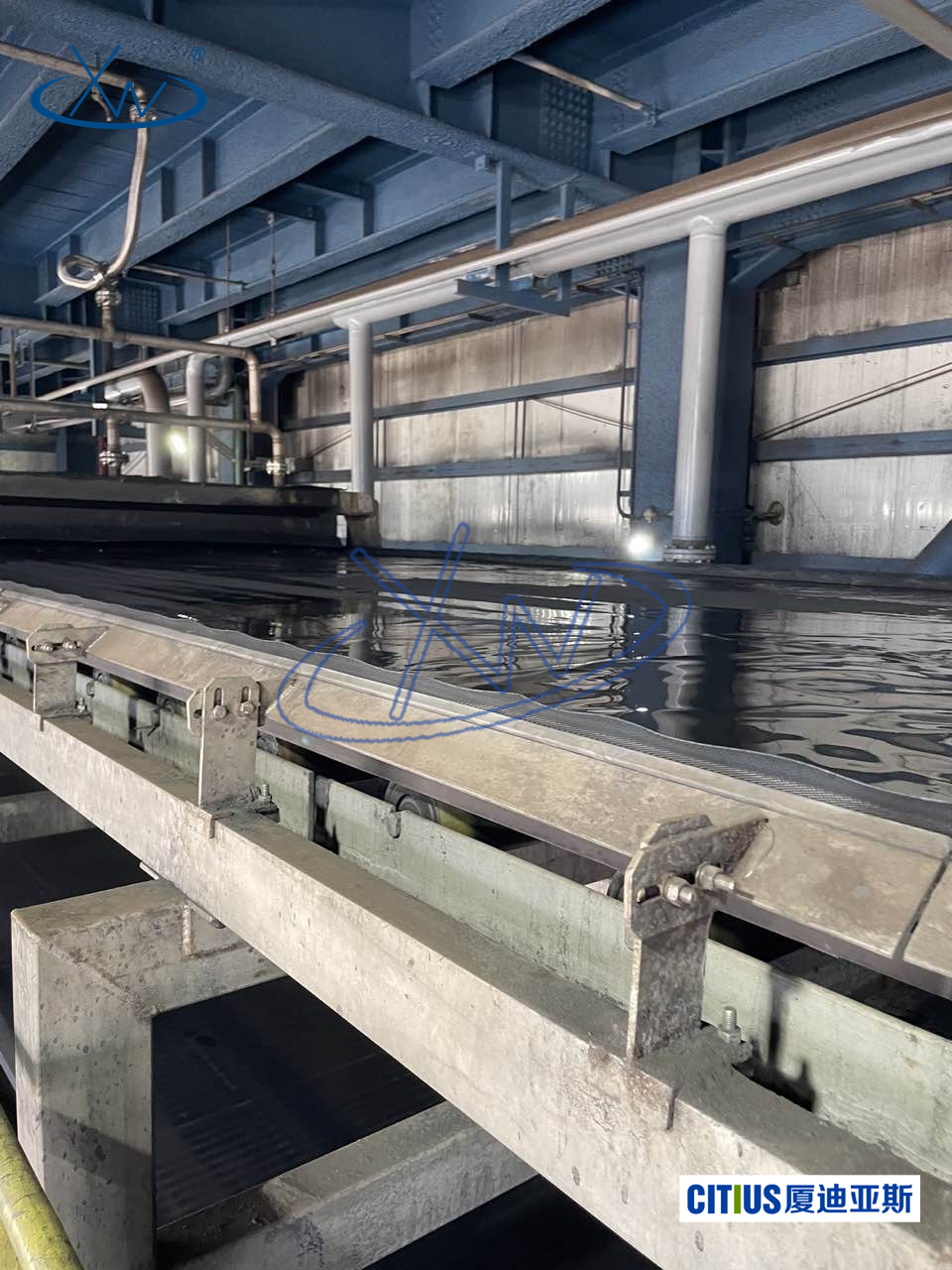

In this crucial link, a traditional yet continuously evolving technology —— the synergistic application of industrial filter cloth and horizontal vacuum belt filter press is being re-recognized and redefined by more and more steel enterprises. Among them, (Xiamen Citius) provided by monofilament filter cloth and non-woven fabric composite structure scheme has become an ideal choice for assisting in the treatment of vanadium iron slag slurry due to its efficient and stable performance.

Vanadium iron primary slag slurry “ Challenges ”

As an important alloy material, vanadium iron produces primary vanadium iron slag slurry during smelting and extraction. This material usually has the following characteristics:

- Complex particle structure :A mixture of large and small particles, with many irregular shapes;

- High specific gravity, poor fluidity :Contains a lot of fine mud and metal oxides;

- High water content :Without effective dehydration measures, it will seriously affect subsequent processing or transportation;

- Strong corrosiveness :Some materials pH is acidic or alkaline, testing the chemical resistance of equipment and materials.

If traditional processing methods are still used, not only will the efficiency be low and the energy consumption high, but it may also lead to secondary pollution, seriously restricting the enterprise's environmental compliance and green development.

Horizontal vacuum belt filter press “ Solution cornerstone ”

Faced with such complex slurry characteristics, Horizontal vacuum belt filter press is gradually emerging as one of the main equipment for industrial solid-liquid separation. This equipment has the following core advantages:

- Continuous operation, strong processing capacity :Especially suitable for continuous large-capacity operations in steel and chemical industries;

- Integrated automation of filtration, washing, and slag discharging :Reduce manual intervention and improve operating efficiency;

- Strong adaptability, adjustable process flow :Flexibly cope with different slurry characteristics.

But the powerful equipment does not mean everything is ready, its real “ soul ” is often hidden in a seemingly ordinary but actually decisive filter cloth —— Filter cloth 。

Industrial filter cloth: A key variable determining efficiency

In horizontal vacuum belt filter presses, filter cloth not only acts as a filtering medium but also affects the operation of the entire production line. For primary vanadium iron slag slurry, filter cloth needs to have the following properties simultaneously:

- High strength and high wear resistance :Adapt to continuous high-speed operation;

- Good filtration accuracy and air permeability :Ensure efficient solid-liquid separation;

- Excellent filter cake release :Reduce clogging and residue, improve regeneration capacity;

- Acid and alkali resistance and corrosion resistance :Adapt to complex chemical environments.

Traditional filter cloths often find it difficult to balance these properties, while Xiamen Citius (Xiamen Citius) through composite technology of monofilament filter cloth and non-woven fabric has provided a breakthrough for this problem.

Monofilament filter cloth + Non-woven fabric: An innovative solution for strong synergy

Monofilament filter cloth: Stable structure, good release

Xiamen Citius (Xiamen Citius) The monofilament filter cloth used by Xiamen Citius is woven from high-strength synthetic fiber monofilaments and has the following advantages:

- Smooth surface, particles are not easily attached;

- Regular pore structure, strong air permeability;

- Fast filtration and filter cake formation can be achieved;

- It has good tensile strength and wear resistance, suitable for long-term operation of belt filter presses.

Non-woven fabric: The invisible assistant for precision filtration “ Helper ”

Non-woven fabric, as an auxiliary layer material, plays an important role when used in combination with monofilament filter cloth:

- Capture fine particles, improve filtrate cleanliness;

- Enhance initial filtration speed;

- Has good flexibility, can buffer mechanical stress;

- Different thicknesses and structures (needle-punched, melt-blown, etc.) can be selected according to actual needs.

Actual performance of double-layer combination

Xiamen Citius (Xiamen Citius) Developed by Composite filter cloth solution After field verification by several steel companies, the following effects have been demonstrated in the treatment of vanadium iron primary slag pulp:

- Improved filtrate clarity 30% Above ;

- Significantly improved filter cake dryness facilitating transportation and reuse;

- Extended filter cloth replacement cycle reducing maintenance costs;

- More stable equipment operation, reducing downtime 。

This composite structure is not just “1+1=2” a simple addition, but a deep technical integration, allowing traditional filter cloths to be revitalized under new operating conditions.

Professional customization and engineering support: Xiamen Xadia (Xiamen Citius) Unique advantages

The excellent performance of the filter cloth is inseparable from the technical research and development and application support behind it. As a Provider of industrial filtration materials and equipment system solutions Xiamen Xadia (Xiamen Citius) has the following industry competitiveness:

- 30 Years of experience in the industrial filtration field serving the steel, mining, chemical and other industries;

- Participation in the formulation of national industry standards reliable technology and a complete system;

- 400+ types of industrial filtration media reserves adapting to the needs of various complex materials;

- Providing one-stop service from selection, trial cloth, optimization to after-sales ;

- Support for co-design of equipment and filter cloth guaranteeing system-level stability and maximum efficiency.

Especially in vanadium iron industry applications, Xiamen Xadia (Xiamen Citius) is not just a filter cloth supplier, but also a “ think tank team for filtration system engineering ”。

Conclusion: Details determine efficiency, professionalism creates green steel

In this slag pulp processing “ seemingly traditional but crucial ” link, industrial filter cloth is no longer just a consumable, but a key node connecting process and environmental protection, efficiency and cost.

Xiamen Xadia (Xiamen Citius) always adheres to “ the concept of serving industry with performance and driving progress with innovation ” by continuously polishing the process and optimizing the structure, providing customized filtration solutions for steel enterprises. The synergistic application of monofilament filter cloth and non-woven fabric is a professional achievement tempered in actual operating conditions.

On the journey of green transformation in the steel industry, every piece of filter cloth may become a force that changes efficiency, and Xiamen Xadia (Xiamen Citius) is willing to be that silent but reliable “ green engine ”。

Previous article: