[Citius] Filtration technology in alumina refining: Innovative application of horizontal vacuum belt filters and filter cloths

Release time:

2024-11-14

Aluminum oxide (Al₂O₃), also known as bauxite, is the main raw material for aluminum extraction. It is an intermediate product extracted from bauxite after chemical treatment, possessing significant industrial value and widely used in aluminum smelting, power generation, chemical industry, and ceramics. The refining process of aluminum oxide includes multiple stages, among which solid-liquid separation is one of the key steps. In this process, the application of horizontal vacuum belt filters and industrial filter cloths plays a crucial role. This article will explore the application of industrial filter cloths in horizontal vacuum belt filters and how they optimize the aluminum oxide refining process in the chemical industry.

1. Definition and Refining Process of Aluminum Oxide

Aluminum oxide (Al₂O₃) is the oxide of aluminum found in bauxite, usually appearing as a white crystalline powder. The refining process of aluminum oxide mainly includes steps such as crushing, grinding, dissolving, precipitating, and filtering of bauxite. The common refining method is the Bayer Process, which converts aluminum in bauxite into a soluble sodium aluminate solution under high temperature and pressure conditions, followed by precipitation and filtration to extract aluminum oxide.

In the refining process of aluminum oxide, the separation between liquid and solid is very critical. After dissolving bauxite, it often forms a slurry containing a large amount of solid impurities that need to be removed using efficient solid-liquid separation equipment. The horizontal vacuum belt filter is one of the most common devices in this process.

2. Working Principle of Horizontal Vacuum Belt Filter

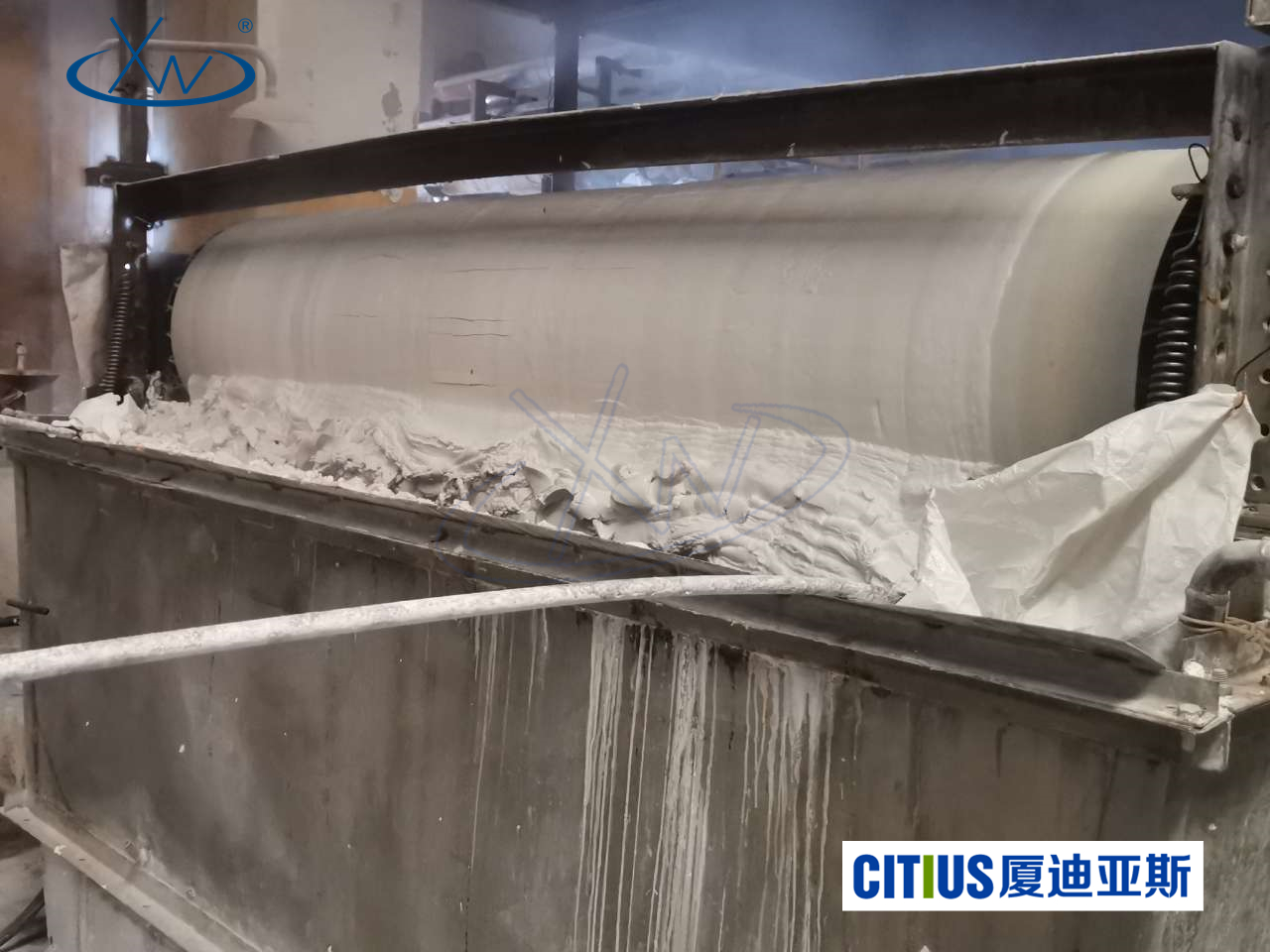

The horizontal vacuum belt filter (Horizontal Vacuum Belt Filter) is a continuous and automated solid-liquid separation device widely used in chemical, mining, metallurgy, and other industries. Its working principle involves using vacuum suction to adsorb solid particles from the slurry onto a belt filter mesh (filter cloth), followed by a series of mechanized operations such as washing, squeezing, and discharging the filter cake to ultimately achieve separation of solids from liquids.

Specifically, the horizontal vacuum belt filter consists of a horizontally arranged belt filter cloth, a vacuum suction box, a filtering tank, a filter cake washing device, and a filter cake discharging device. During the filtering process, the slurry passes through the filter cloth for filtration; liquids are sucked into the vacuum box while solid particles are retained on the surface of the filter cloth to form a filter cake. The filter cake is then washed and squeezed to remove residual liquid impurities before being discharged.

3. Role of Industrial Filter Cloths in Horizontal Vacuum Belt Filters

In horizontal vacuum belt filters, industrial filter cloths are key filtering media that directly affect filtration efficiency and equipment operational efficiency. The refining process of aluminum oxide requires efficient solid-liquid separation; thus, the material, structure, and performance of the filter cloth are crucial to this process.

1. Selection of Filter Cloth Material

The filtering liquid in the aluminum oxide refining process is usually strongly alkaline or in high-temperature environments; therefore, the filter cloth must possess excellent chemical corrosion resistance and high-temperature performance. Common filter cloth materials include polyester, polypropylene, polyvinyl chloride (PVC), and special synthetic fibers; these materials can withstand strong alkaline solutions' erosion while maintaining good filtration performance at high temperatures.

Additionally, the filter cloth needs to have certain wear resistance because solid particles cause significant wear on the cloth during filtration processes, especially when dealing with high-concentration slurries. Therefore, selecting filter cloths with strong wear resistance can extend their service life and reduce equipment maintenance frequency.

2. Porosity and Structural Design of Filter Cloths

The porosity and structural design of filter cloths directly affect their filtration efficiency and drying effect of the filter cake. In the refining process of aluminum oxide, the filter cloth needs to effectively capture small particle impurities to prevent them from entering the liquid. At the same time, the pore size of the filter cloth must be designed according to the required filtration precision to avoid clogging due to overly small pores or poor filtration results due to overly large pores.

When selecting filter cloths, it is also necessary to consider their air permeability and liquid passage speed to ensure that liquids can quickly pass through while solid particles are efficiently retained. The design of the filter cloth should balance filtration efficiency with flow rate to ensure production efficiency and filtration effectiveness.

3. Cleaning and Maintenance of Filter Cloths

In the refining process of aluminum oxide, due to a large number of solid particles in the slurry, filter cloths are prone to clogging; thus regular cleaning is crucial. Horizontal vacuum belt filters are typically equipped with automatic cleaning systems that use high-pressure water or chemical cleaning solutions to remove solid materials from the filter cloth. A good cleaning system can effectively prevent clogging and improve equipment operational efficiency.

Moreover, regular inspection and replacement of filter cloths are also important for ensuring normal equipment operation. Regularly checking for wear on filter cloths and promptly replacing damaged ones can reduce downtime and improve production efficiency.

4. Advantages of Horizontal Vacuum Belt Filters in Aluminum Oxide Refining

Horizontal vacuum belt filters have significant advantages in aluminum oxide refining due to their unique design and working principle:

1. Efficient Solid-Liquid Separation

Horizontal vacuum belt filters can achieve efficient solid-liquid separation through large-area filter cloths and vacuum suction. In aluminum oxide refining processes where solid impurity particles are relatively fine, traditional filtering methods may not achieve ideal results. However, horizontal vacuum belt filters can fully utilize their large filtering area and vacuum suction advantages to ensure effective removal of solid impurities and obtain high-purity aluminum oxide.

2. Continuous and Automated Operation

Horizontal vacuum belt filters are continuous automated devices capable of running non-stop for 24 hours to meet large-scale production demands. In aluminum oxide refining processes, stable and continuous filtering is crucial. This equipment can flexibly adjust filtering speed and pressure through an automatic control system to ensure efficient stable operation.

3. Energy Saving and Environmental Protection

Compared with traditional filtering equipment, horizontal vacuum belt filters have lower energy consumption. Their efficient use of vacuum suction allows for completion of filtering processes at lower energy costs. Additionally, automatic cleaning systems and efficient use of filtering media also reduce wastewater and waste liquid emissions, meeting modern environmental protection requirements.

5. Conclusion

The refining process of alumina involves complex solid-liquid separation operations. Horizontal vacuum belt filters, with their efficient filtration performance, low energy consumption, and advantages of automated control, have been widely used in alumina refining. Industrial filter cloths, as filtering media, play a crucial role in improving filtration efficiency, extending equipment lifespan, and ensuring product quality. With continuous technological advancements, filter cloth materials and designs will become more adaptable to different process requirements, promoting the alumina refining process towards a more efficient and environmentally friendly direction.