Application and Performance Analysis of Citius High-Precision Filter Cloth in the Preparation of Caffeine Derivatives

Release time:

2025-03-06

1. Challenges in Filtration during the Production of Caffeine Sodium (Caffeine Synthesis)

Caffeine Sodium (Caffeine Sodium Benzoate) is a derivative of caffeine, widely used in the pharmaceutical and food industries as a stimulant or food additive. During its production process, solid-liquid separation technology is crucial, directly affecting the purity, quality, and yield of the final product. However, due to the involvement of fine particles, colloidal substances, and complex chemical media during the synthesis process, the filtration system must possess the following characteristics:

- Ultra-high precision retention, ensuring effective removal of impurities and improving product purity.

- High permeability, ensuring efficient liquid passage and enhancing production efficiency.

- Chemical corrosion resistance, adapting to various chemical solvents during the synthesis process, extending the lifespan of the filter cloth.

- Anti-blocking capability, reducing surface fouling and pore blockage of the filter cloth, lowering maintenance frequency.

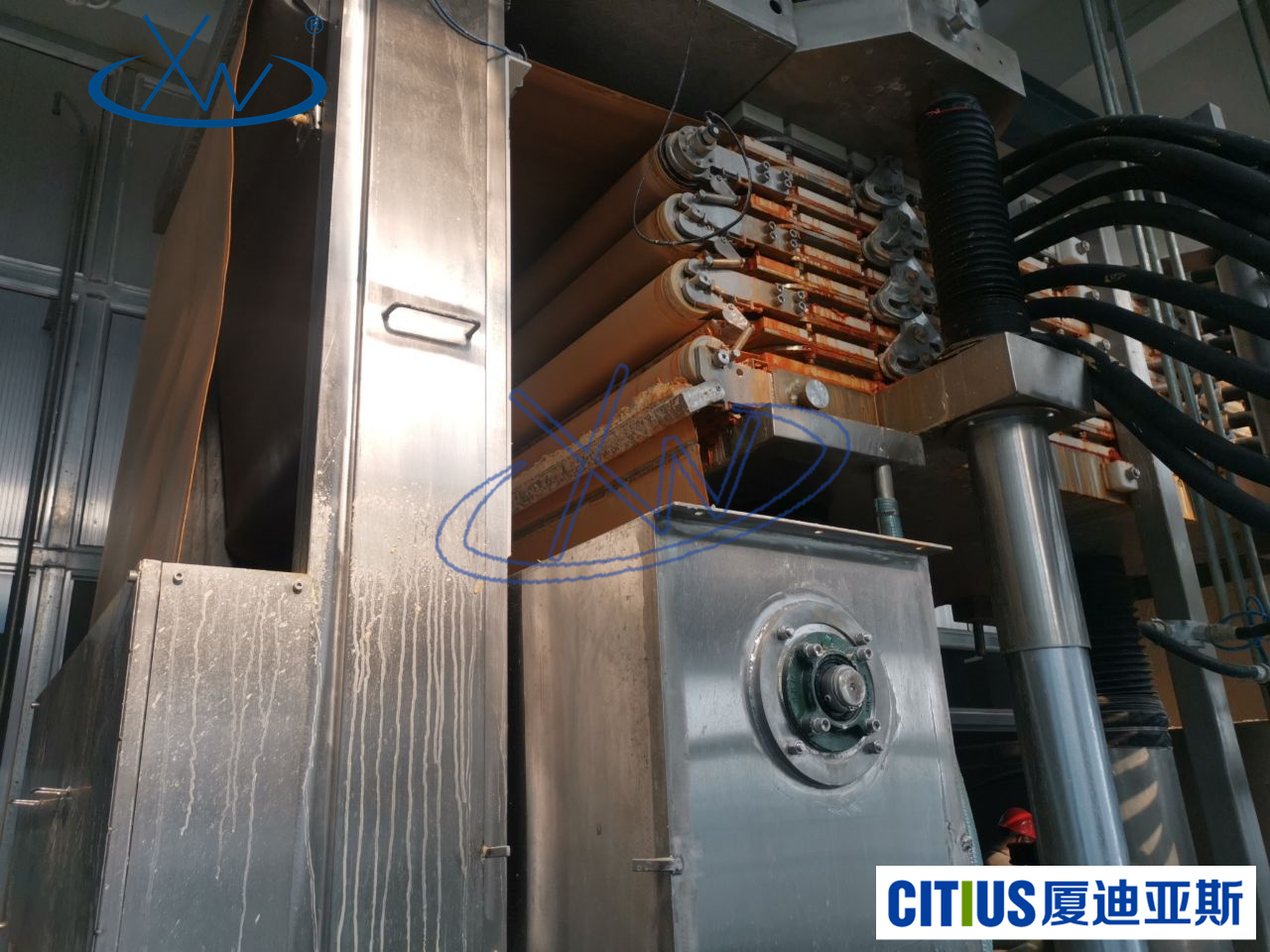

2. The Role of Vertical Filter Press in Caffeine Sodium Production

The vertical filter press is an efficient solid-liquid separation device, widely used in industries such as pharmaceuticals, chemicals, and food. Its main roles in the production of caffeine sodium (caffeine synthesis) include:

- High-pressure filtration, improving dehydration efficiency——Under high pressure, the filter cloth can efficiently separate solids from liquids, allowing for full recovery of the target material.

- Small footprint, large filtration area——Compared to traditional plate and frame filter presses, vertical filter presses occupy less space and are suitable for large-scale production.

- High degree of automation, easy operation——Reducing manual intervention, improving production stability and efficiency.

In this process, the choice of filter cloth directly affects filtration quality and equipment operating efficiency. Xiamen Citius(Xiamen Citius)Developed a filter cloth with ultra-high retention precision suitable for vertical filter presses to meet the special needs of caffeine synthesis,providing better solid-liquid separation solutions for production enterprises.3. Technical Advantages of Xiamen Citius Ultra-high Retention Precision Filter Cloth

Xiamen Citius(Xiamen Citius)Ultra-high retention precision filter cloth possesses the following core technical advantages to meet the high standard requirements of solid-liquid separation during caffeine synthesis:

Ultra-high precision retention, ensuring product purity(Xiamen Citius)Using special weaving technology, precisely controlling pore size to achieve sub-micron level solid particle retention, effectively removing impurities and improving the purity of caffeine sodium products.

- Suitable for the separation of fine particles and colloidal substances, ensuring that the final product meets pharmaceutical industry standards.

- High permeability, enhancing filtration efficiency

- Optimized fiber arrangement structure allows for rapid liquid phase passage, increasing filtration rate and reducing production cycle.

- High permeability, enhancing filtration efficiency

- Reducing filtration resistance, improving production efficiency, and lowering energy consumption.

- Excellent anti-pollution performance, reducing cleaning frequency

- The smooth surface of the filter cloth and strong sludge stripping ability reduce solid residue, prevent blockage, and improve regeneration capability.

- Excellent anti-pollution performance, reducing cleaning frequency

- Adapting to complex chemical environments, effectively resisting chemical erosion during the synthesis of pharmaceutical caffeine sodium, maintaining long-term stable operation.

- Strong durability, reducing operating costs

- Using high-strength, wear-resistant fiber materials to improve tensile strength, adapting to high-pressure filtration environments, and extending the lifespan of the filter cloth.

- Strong durability, reducing operating costs

- Special chemical treatment enhances acid and alkali resistance, reducing filter cloth replacement frequency and lowering long-term usage costs.

- Customized design to meet different process requirements

- Xiamen Citius

- Customized design to meet different process requirements

- provides various specifications of ultra-high retention precision filter cloth, which can be optimized in weaving methods, pore sizes, edge reinforcement treatments, etc., according to customer needs, to adapt to different types of vertical filter presses.

- Optional anti-static and anti-pollution coatings to enhance applicability in special environments.(Xiamen Citius)4. Practical Application of Xiamen Citius Filter Cloth in Caffeine Synthesis Filtration

- In a well-known pharmaceutical company's caffeine synthesis production line, the existing filtration system faced issues of unstable filtration precision, easy clogging of the filter cloth, and high solid loss rates, resulting in the final product's purity not meeting expected standards. After replacing it with Xiamen Citius

- Optional anti-static and anti-pollution coatings to enhance applicability in special environments.(Xiamen Citius)4. Practical Application of Xiamen Citius Filter Cloth in Caffeine Synthesis Filtration

ultra-high retention precision filter cloth, the following significant results were achieved:(Xiamen Citius)Increased product purity

: The precise filtration capability of the filter cloth ensured the efficient removal of fine impurities, with the final caffeine sodium product purity reaching pharmacopoeia standards.(Xiamen Citius)Improved filtration efficiency

- : The optimized permeability design accelerated the solid-liquid separation process, increasing the processing volume per unit time by approximately.

- Reduced maintenance costs: The high durability material and excellent anti-pollution capability reduced cleaning frequency and replacement times, lowering long-term operating costs.30%User feedback indicates that the application of Xiamen Citius

- filter cloth significantly enhanced production stability, making equipment operation smoother and reducing downtime caused by filter cloth replacement or cleaning during the production process.5. Conclusion

Feedback from users indicates that Xiamen Citius Filter Media significantly improved production stability, making equipment operation smoother and reducing downtime caused by filter cloth replacement or cleaning during the production process.

In the production process of pharmaceutical tea sodium (caffeine synthesis), the solid-liquid separation stage is crucial, placing extremely high demands on the retention accuracy, chemical corrosion resistance, and filtration efficiency of the filter cloth. Shadia.(Xiamen Citius)With years of experience in industrial filtration technology, the specially developed filter cloth with ultra-high retention accuracy has successfully assisted pharmaceutical companies in optimizing production processes, improving product quality, and reducing operating costs.

In the future, Shadia.(Xiamen Citius)will continue to deepen its efforts in the field of filtration technology, providing more efficient and durable filtration solutions for high-end manufacturing industries such as pharmaceuticals and fine chemicals, supporting industry development, and achieving higher economic benefits and environmental protection goals.