30 years of technical expertise, Xiamen Xadiyas vertical filter press cloth solutions in the pesticide industry!

Release time:

2025-09-01

1. Introduction

In modern industrial production, solid-liquid separation technology has become an indispensable part of multiple industries. Whether in metallurgy, chemical engineering, pharmaceuticals, food, or environmental protection, the performance of filtration equipment and filter materials directly affects production efficiency, product quality, and environmental protection. In the pesticide manufacturing industry, especially in the production process of glyphosate, the solid-liquid separation stage is critical. As one of the most widely used herbicides globally, glyphosate is produced on a large scale, and its separation and filtration tasks mainly rely on filter presses and their matching industrial filter cloths.

This article will focus on Xiamen Xiadias Vertical Filter Cloth for Filter Presses in the Pesticide Industry to discuss its functions and advantages in glyphosate production, combined with the market development trends in the pesticide industry, analyzing the application characteristics and future prospects of Xiamen Xiadias filter cloth products.

Processed material: pesticide glyphosate

2. Market Background of the Pesticide Industry

1. Overview of the Pesticide Industry

Pesticides are essential materials to ensure agricultural production and play a core role in global food security and stable crop yields. With global population growth and limited arable land resources, the overall demand for pesticides is on the rise. China, as a major global producer and consumer of pesticides, holds strong market advantages in subfields such as herbicides, insecticides, and fungicides.

2. Market Position of Glyphosate

Glyphosate is a broad-spectrum, systemic herbicide whose high efficiency and low residue characteristics make it one of the most widely used herbicides worldwide. Especially after the promotion of genetically modified crop planting, the market demand for glyphosate has continued to expand. According to relevant statistics, the global annual demand for glyphosate exceeds 700,000 tons, with China dominating in production capacity and exports.

However, the production process of glyphosate is complex, generating large amounts of by-products, wastewater, and waste residue, which impose higher requirements on separation and environmental protection. This is precisely where the filter cloth of the filter press plays a key role.

Filter press type: vertical filter press

3. Glyphosate Production Process and Filtration Stage

The main production routes for glyphosate are the glycine method and the double glyphosate method . Both processes involve steps such as reaction, extraction, crystallization, and separation, with solid-liquid separation being an indispensable key stage.

- Filtration of reaction slurry

During synthesis, a large amount of solid by-products are produced, which need to be separated by filter press. The filter cloth must be resistant to strong alkali, high temperature, and have high filtration precision.

- Mother liquor recovery and crystallization

The crystallization step of glyphosate requires repeated separation and washing. The filter cloth at this stage must ensure high water permeability and retention capacity while preventing loss of crystallized particles.

- Wastewater and waste residue treatment

The waste liquid from glyphosate production contains a large amount of organic substances and salts, and direct discharge causes serious pollution. After treatment by filter press, the chemical oxygen demand (COD) and suspended solids in the waste liquid can be effectively reduced, with the filter cloth playing a core role in this process.

Filter cloth model used: vertical filter press filter cloth

4. Characteristics and Application Requirements of Filter Cloth for Filter Presses

1. Chemical corrosion resistance

The glyphosate production process uses many chemicals such as strong alkalis and strong oxidants. The filter cloth needs to have excellent acid and alkali resistance.

2. High strength and wear resistance

During operation, the filter press undergoes frequent mechanical pressing and repeated washing. The filter cloth must have strong tensile strength and tear resistance to ensure service life.

3. Balance between filtration precision and permeability

The filter cloth must effectively retain solid particles while allowing filtrate to pass quickly, improving filter press processing efficiency. This places higher demands on weaving technology and pore size design.

4. Anti-clogging performance

The particle size distribution of glyphosate reactants is uneven and easily clogs the filter cloth pores. High-performance filter cloth can improve slag discharge efficiency and reduce clogging.

5. Cleaning and regeneration performance

In continuous production, the filter cloth easily accumulates organic matter or inorganic salt crystals. High-quality filter cloth must have good adaptability to water washing and chemical cleaning for repeated use, reducing operational costs.

Filter cloth model used: vertical filter press machine filter cloth

5. Combined Advantages of Vertical Filter Press and Specialized Filter Cloth

In recent years, vertical filter presses have been increasingly adopted by glyphosate production enterprises due to their high automation, small footprint, and high filtration efficiency. Compared with traditional plate and frame filter presses, vertical filter presses are more efficient in filtrate discharge and filter cake removal. These advantages need to be fully realized through high-performance filter cloth:

Automatic cake discharge The filter cloth must ensure uniform filter cake formation, easy detachment, and reduce manual intervention.

Adaptation to high concentration slurry During glyphosate production, the solid content is high, so the filter cloth must have strong load-bearing capacity.

Long-cycle stable operation High-strength filter cloth can maintain stable performance during long-term operation of the vertical filter press, avoiding frequent replacements.

6. Application Characteristics of Industrial Filter Cloth in the Pesticide Industry

Strong specificity The slurry properties vary greatly in different pesticide production processes, and the filter cloth needs to be customized according to process parameters such as pore size, material, and weave.

Environmental drive The pesticide industry faces significant environmental pressure, and filter cloth plays a decisive role in reducing wastewater and waste residue emissions.

Cost sensitivity The pesticide industry is highly competitive; filter cloth must ensure performance while also considering economy and durability.

Clear upgrade trend With the popularization of intelligent and automated equipment, filter cloth is developing towards high efficiency, long service life, and low energy consumption.

Filter press type: vertical filter press

7. Core advantages of Xiamen Xiadias in the industrial filter cloth field

1. Industry status and R&D strength

Industry standard setter : Xiamen Xiadias is the drafting unit of the industry standard for belt filter machine filter belts and holds industry discourse power.

National high-tech enterprise has 9 invention patents and 11 utility model patents and continues to innovate.

Strong R&D resources Cooperates with research institutions such as Donghua University to develop core technologies including nano-scale filter media, high retention precision filter materials, and high-temperature resistant conveyor belts.

2. Material innovation and application breakthroughs

Xiamen Xiadias can develop and produce various special monofilament materials:

PET series: standard and high hydrolysis resistance types, suitable for acidic or humid environments.

PA series: PA6, PA66, PA610, etc., featuring high strength and wear resistance.

PP series: including high-temperature resistant PP, combining acid and alkali resistance with lightweight advantages.

PPS, PEEK, PTFE series: suitable for extreme high temperature and highly corrosive environments, meeting the demanding conditions of the pesticide industry.

These functional fibers break the limitations of traditional filter cloth materials, enabling Xiadias to provide specialized solutions for glyphosate slurry characterized by high alkalinity, high salinity, and uneven particles.

3. Precision weaving and process treatment

Xiadias masters the full production process from slice adhesion, drawing, warping to weaving, setting, cutting, and edge sealing .

4. Full-process quality control

ISO9001 quality management system certification ;

Weaving breathability, tensile strength, and acid-alkali resistance are strictly tested;

each batch of filter cloth undergoes full inspection to ensure consistency and stability.

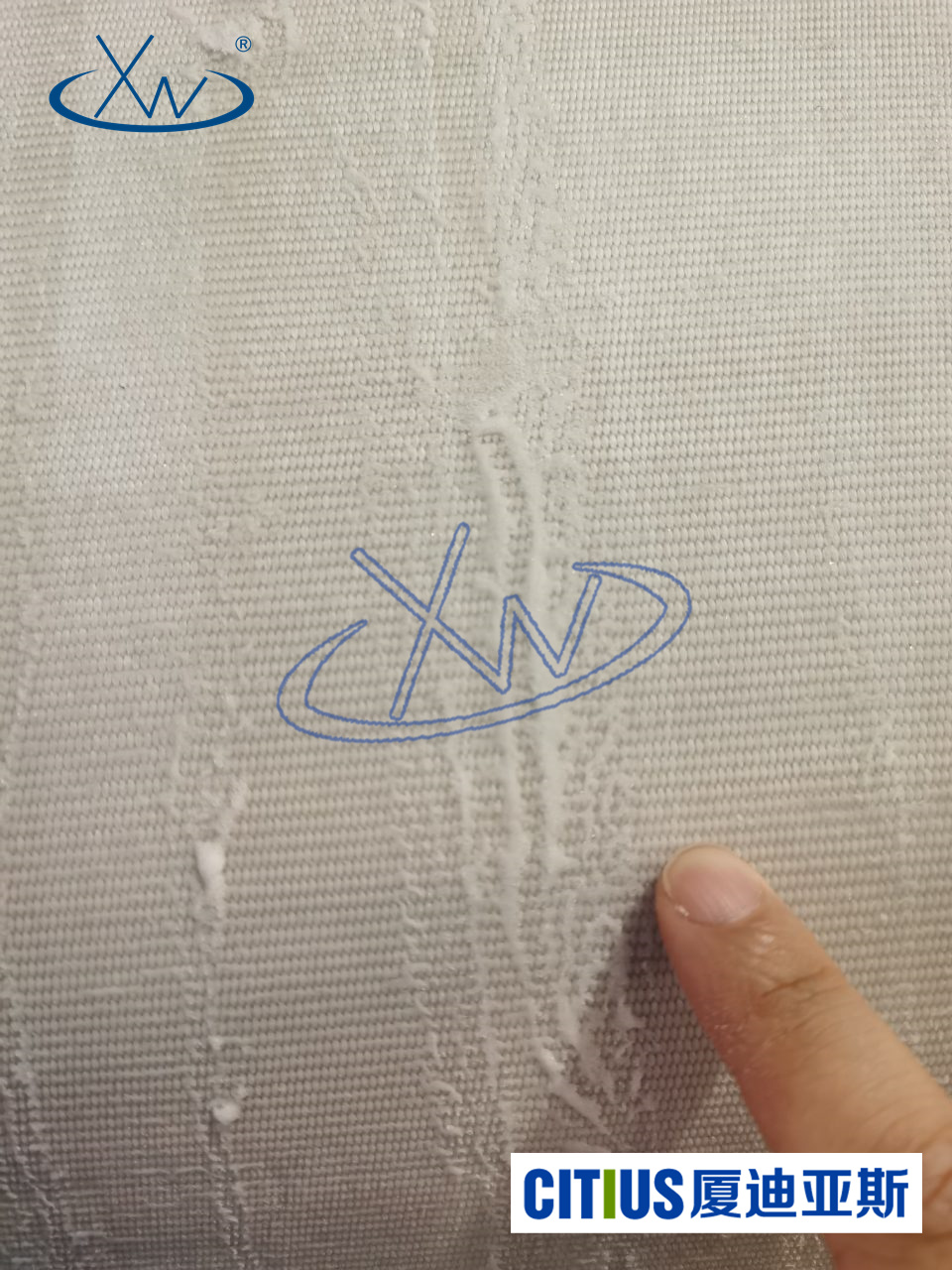

A corner of Xiamen Xiadias laboratory

8. Summary

Xiamen Xiadias Filtration Materials Technology Co., Ltd. With over thirty years of deep cultivation and innovation, from material R&D to process weaving, from setting domestic industry standards to expanding international markets, it has grown into a leader in the industrial filter cloth field and plays a vital role in glyphosate and pesticide production.

Against the backdrop of continuous growth in the global pesticide market and increasing environmental pressure, the technological upgrades and application optimizations of Xiamen Xiadias filter cloth products are becoming the focus of industry attention. With the continuous application of new materials and new processes, Xiamen Xiadias vertical filter press special filter cloth will be more widely and finely applied in the pesticide industry.

For large pesticide manufacturers such as glyphosate, choosing the right filter press cloth is not only key to optimizing production processes, improving solid-liquid separation efficiency, and product quality, but also directly related to environmental compliance and corporate economic benefits, serving as an important guarantee for achieving green and sustainable development.

Looking to the future, Xiadias will continue to uphold the philosophy of "technological innovation + lean manufacturing" to provide high-performance, customized, and sustainable filtration solutions for the pesticide industry and more global industrial fields.

Previous article: