In-Depth Analysis: The Key Role of Citius Industrial Filter Cloth in Aluminum Industry Resource Utilization

Release time:

2025-03-05

Aluminum Industry Observation: Optimization of Demand Structure and Emerging Supply-Demand Gap

On February 28, 2025, the Nonferrous Metals Processing Industry Association released the 2024 aluminum processing material production data, revealing the dynamic changes in China's aluminum downstream demand. The data shows thatthe total aluminum production growth rate reached 4.4%, with a five-year compound annual growth rate (CAGR) of 3.9%., confirming the robust demand for aluminum as a basic material. Although the drag effect of the real estate sector on aluminum demand is significant, the production of industrial aluminum profiles has surpassed that of construction aluminum profiles for the first time, combined with the growth in demand from other sectors, providing important support for the industry. Looking ahead to 2025, the growth rate of primary aluminum supply is expected to drop below 2%.The supply-demand gap may further widen, and aluminum prices and smelting profits may continue to operate at high levels.

1. Structural Adjustment of Downstream Aluminum Demand

The Rise of Industrial Aluminum Profiles Filling the Gap in Real Estate Demand

In 2024, the drag on aluminum demand from the real estate sector reached 6%, but the production of industrial aluminum profiles has surpassed that of construction aluminum profiles for the first time, becoming a key source of incremental growth. Industrial aluminum profiles are widely used in machinery, transportation, and other fields, and their growth not only compensates for the decline in the construction sector but also reflects the driving effect of China's manufacturing transformation and upgrading on aluminum demand.

Lightweight and Functional Materials Drive Application Expansion

The penetration rate of aluminum in new energy, electronics, and other fields continues to rise. As a lightweight structural material, the process of aluminum replacing traditional materials in automobiles and aerospace is accelerating; with excellent electrical and thermal conductivity, its application scenarios in power equipment and consumer electronics are continuously expanding. The simultaneous growth of demand across multiple fields highlights the strategic value of aluminum as a functional material.

Resilience of Demand in Other Fields Supports the Overall Situation

In addition to industrial profiles, the production of segmented categories such as aluminum plates, strips, and foils has also achieved growth. For example, the home appliance sector benefits from the continuation of the "national subsidy" policy, maintaining stable aluminum consumption; power investment remains at a high growth rate, further driving the demand for aluminum in power transmission and transformation equipment. The structural adjustment of diversified demand effectively alleviates the impact of fluctuations in a single field on the industry.

2. Supply-Demand Pattern and Industry Challenges in 2025

Demand growth rate is expected to remain stable.

Although the growth rate of new energy vehicles may slow down and the increase in aluminum demand in the photovoltaic sector is limited, the supporting role of power investment and home appliance consumption remains significant. Coupled with the peak period of real estate drag having passed, the growth rate of aluminum demand in 2025 is expected to be similar to recent levels, with no significant deviation.

The peak of primary aluminum supply exacerbates supply-demand contradictions.

2025 is seen as the peak year for the growth rate of China's primary aluminum supply, with an expected annual supply growth rate of less than 2%. As electrolytic aluminum capacity approaches policy limits, the release of new capacity is restricted, while demand maintains rigid growth, the industry may face a supply-demand gap. In this context, aluminum prices and profits in the smelting segment may remain high, or even reach new highs.

Risk factors still present uncertainties.

Global macroeconomic fluctuations may suppress aluminum demand growth, while rising energy prices and stricter environmental protection policies will increase smelting costs. In addition, the impact of upgraded safety production supervision on capacity stability also needs close attention. The industry needs to respond to multiple challenges under tight supply-demand balance and solidify the foundation for long-term development.

In-depth Analysis: The Key Role of Xiadias Industrial Filter Cloth in the Resource Utilization of the Aluminum Industry

In the production and processing of the aluminum industry, the treatment of by-products such asaluminum ash and red mudhas always been a focus of industry attention. In recent years, with the promotion ofgreen manufacturing and resource utilization, the aluminum industry has gradually explored more efficient solid-liquid separation technologies to achieve waste reuse. Xiamen Xiadias Filter Material Technology Co., Ltd. relies on itsleading industrial filter cloth technology, providing reliable filtration solutions in multiple links such asaluminum ash treatment, red mud dewatering, and 4A zeolite production, contributing to the sustainable development of the aluminum industry.

1. Aluminum Ash Treatment: Efficient Filtration Aids in Aluminum Metal Recovery

Aluminum ash containsunoxidized aluminum metal, alumina, and other by-products, recovering aluminum metal and valuable components from it is key to improving resource utilization. Xiadias'high-precision filter clothis widely used in the solid-liquid separation process of aluminum ash, ensuring:

Efficient Dewatering: The filter cloth has excellent water permeability and filter cake release properties, ensuring that aluminum ash dewaters quickly during the separation process, improving production efficiency.

Corrosion Resistance and High Temperature Resistance: In the high temperature and chemical corrosion environment of aluminum ash treatment, Xiadias filter cloth maintains stable performance and extends service life.

Optimized Solid-Liquid Separation: Effectively removes impurities, improves aluminum recovery rate, and reduces production costs.

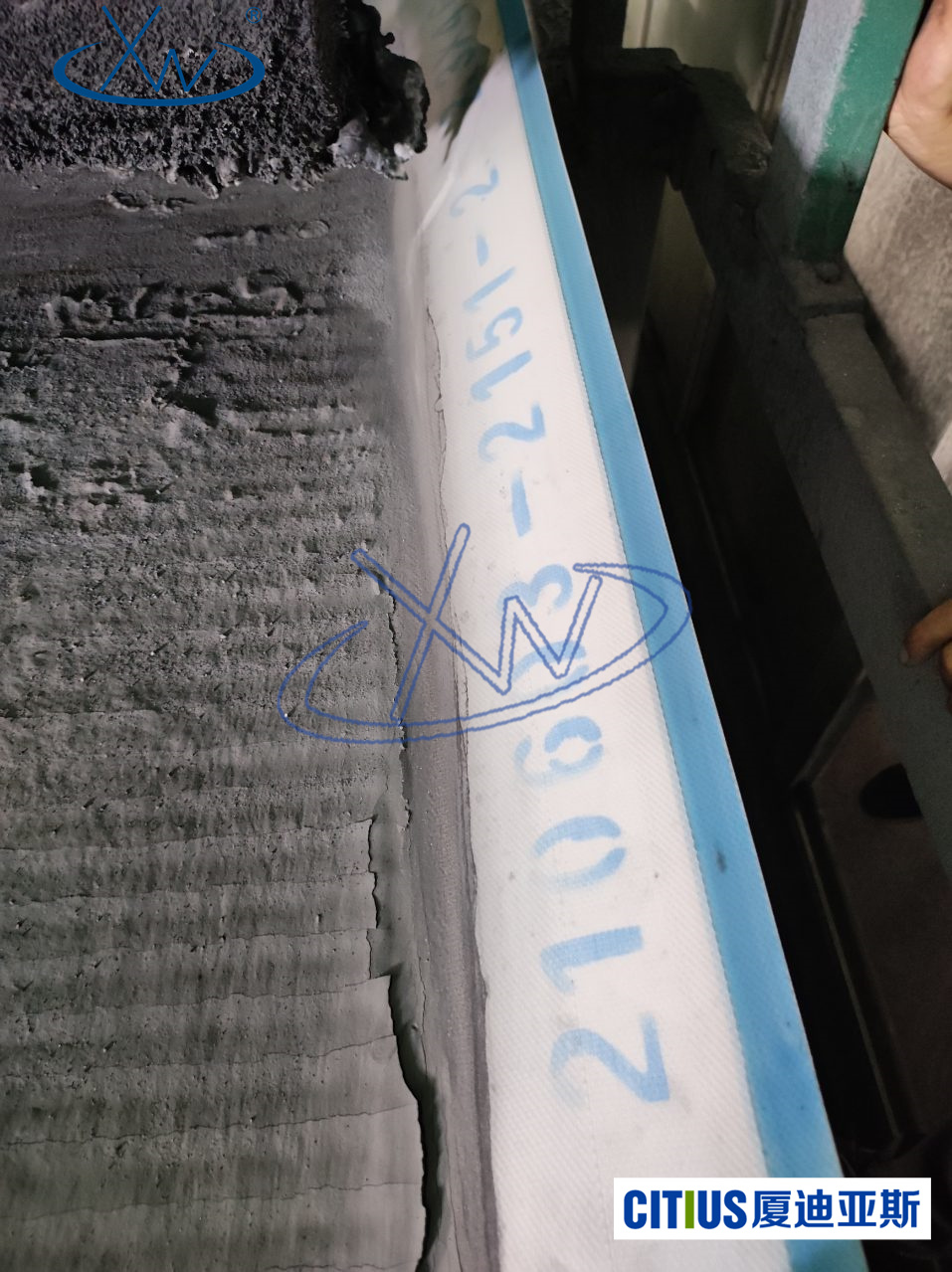

Aluminum Ash(Horizontal Vacuum Filter)Treatment Site Diagram

2. Red Mud Treatment: Environmental Protection Dewatering to Achieve Low Emission Goals

Red mud is a highly alkaline waste residue produced during the production of alumina, and how to reduce its moisture content and decrease storage volume has always been a challenge for the industry. The filter cloth provided by Xiadias is specially designed forred mud dewatering.Design to help enterprises achieve environmental emission standards:

Rapid dehydration to reduce storage pressureThe unique weaving technology of Citius filter cloth canefficiently separate red mud from moisture, reducing the moisture content of red mud, thereby decreasing subsequent storage area and treatment costs.

Strong alkali resistance and long service lifeRed mud is rich in alkaline substances, and ordinary filter cloth is easily damaged, while Citius filter cloth usesexcellent alkali resistancematerials to ensure long-term stable operation.

Environmental compliance to support sustainable development: By efficient filtration, improve the recovery rate of residual aluminum components in red mud, while reducing wastewater pollution to achieve green production.

Red mud (plate and frame filter press) treatment site diagram

3, 4A zeolite production: solid-liquid separation promotes new material applications

4A zeolite is an environmentally friendly material widely used indetergents, water treatment, catalyst carriers, and other fields, while aluminum ash, red mud, and other by-products are important raw materials for it. Citius filter cloth plays a crucial role in the production process of 4A zeolite:

Assisting in the synthesis of high-purity 4A zeolite: In the hydrothermal synthesis process, Citius filter cloth ensures efficient solid-liquid separation of raw materials, removes impurities, and improves product purity.

Improving filtration efficiency and optimizing energy consumption: By precise filtration accuracy, reduce subsequent refining processes and improve overall production efficiency.

Compatible with various filtration equipment: Citius filter cloth can be widely applied tobelt press filter, horizontal vacuum belt filter, vertical filter press, drum filter, and other equipment to meet the production needs of different enterprises.

4A zeolite (vertical filter press) treatment site diagram

4, Citius: An important partner for sustainable development in the aluminum industry

As a global leading manufacturer of filtration materials, Citius not only provideshigh-performance industrial filter cloth, but also offerscustomized filtration solutions, ensuring a more efficient and environmentally friendly production process. With years of experience and technological accumulation, Citius has become a trusted partner for many aluminum enterprises.

In the key links of aluminum ash recovery, red mud dehydration, and 4A zeolite production, Citius industrial filter cloth, with itsefficient filtration, corrosion resistance, and optimized separationadvantages, helps enterprises achieveefficient resource utilization, environmental protection, and cost optimization..

On the road to greening and recycling in the aluminum industry, Citius has always worked alongside the industry to promote sustainable development. If you want to know more about the applications of Citius filtration materials, please