In-depth Analysis | Why is the dewatering effect of your plate and frame filter press always poor? It may be that the filter cloth is not selected correctly!

Release time:

2025-03-04

In industrial production,solid-liquid separationis a crucial process, involvingwastewater treatment, mineral processing, chemical filtration, food and pharmaceuticalsand many other industries. Among these industries,the plate and frame filter pressas an efficient filtering device, undertakes tasks such as sludge dewatering, mineral concentration, and waste liquid recovery. However, many people encounter such troubles:

✅ Why does the filter cloth get clogged shortly after use?

✅ Why is the dewatering speed getting slower?

✅ Why is the filter cake still wet after pressing?

✅ Why is the filter cloth replaced so frequently, and the costs remain high?

In fact, the root cause of these problems is likelynot that your equipment is inadequate, but that the filter cloth was not chosen correctly!Today, we will deeply analyzethe importance of the filter cloth for the plate and frame filter press,as well as how to choose a trulyefficient and durable filter cloth, to enhance your filtration efficiency50%!

1. The importance of filter cloth to the plate and frame filter press

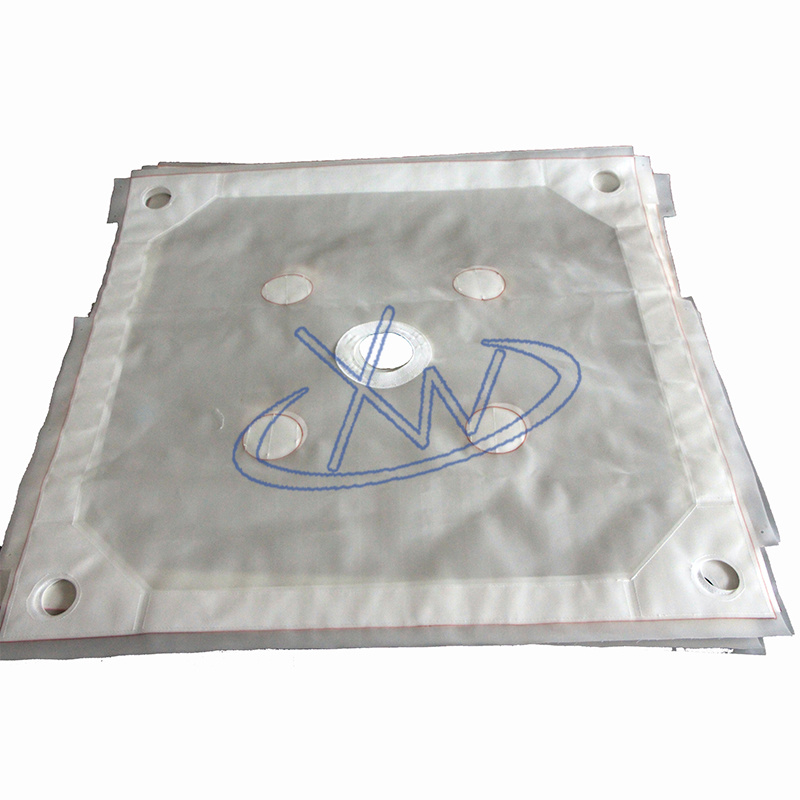

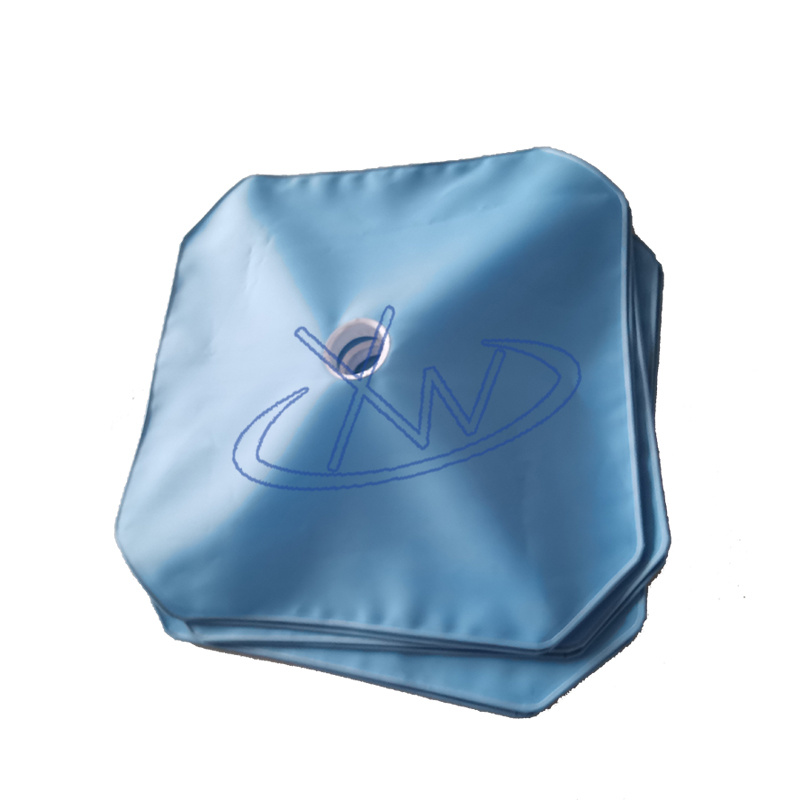

In the filtration process of the plate and frame filter press, the role of the filter cloth is toallow liquids to pass through while retaining solids,ultimately forming a filter cake. If the quality of the filter cloth is poor, or if it is not chosen correctly, it may lead to a series of problems, such as:

❌ poor permeability, slow filtration speed, reducing production efficiency

❌ easily clogged, leading to frequent replacements, increasing operational costs

❌ poor durability, breaking down in a short time, affecting normal equipment operation

❌ difficult filter cake release, turning every unloading into a nightmare.

Therefore, choosing the right filter cloth is equivalent to equipping your plate and frame filter press with a"high-efficiency filter element", making the filtration process faster, smoother, and more energy-efficient!2. Are all filter cloths on the market really suitable for you?

Currently, there are many types of filter cloths for plate and frame filter presses on the market, ranging from

ordinary polypropylene filter cloth, polyester filter cloth, to high-performance composite filter cloths,each material has different applicable ranges. Randomly buying a filter cloth may lead topoor filtration, skyrocketing costs, frequent cloggingand other issues.How to choose the right filter cloth for you?

Look at the material

✅ —— for example, polypropylene is suitable for acidic environments, polyester is more alkali-resistant, and high-temperature environments require high-temperature resistant filter cloth.Look at the weaving process

✅ monofilament woven cloth has strong permeability, multifilament woven cloth has good durability, and choosing the right structure can maximize performance.for example, polypropylene is suitable for acidic environments, polyester is more alkali-resistant, and high-temperature environments require high-temperature resistant filter cloth.Look at the aperture size

✅ if the filtration precision is too low, solids will be lost; if the precision is too high, it is easy to clog, and permeability will worsen.for example, polypropylene is suitable for acidic environments, polyester is more alkali-resistant, and high-temperature environments require high-temperature resistant filter cloth.Look at the applicable industries

✅ the solid-liquid separation needs of industries such as mineral processing, chemicals, pharmaceuticals, and food are different, requiring customized filter cloth.for example, polypropylene is suitable for acidic environments, polyester is more alkali-resistant, and high-temperature environments require high-temperature resistant filter cloth.Therefore, buying filter cloth cannot be done casually,

choosing the right one can yield twice the result with half the effort; choosing the wrong one can double the loss!3. Recommendation: A truly efficient and durable filter cloth!

Why are more and more companies choosing Xiamen Citius?

If you are looking forefficient and durable plate and frame filter press filter cloth,then the filter cloth from Xiamen Citius

Filtration Materials Technology Co., Ltd.is definitely worth recommending! Why?🔹Years of industry experience, specializing in manufacturing industrial filter clothsefficient and durable plate and frame filter press filter cloth,the filter cloth has high wear resistance, anti-clogging, and good permeability, suitable for various complex working conditions.Customized solutions, providing filter cloth solutions that fit different industries.

Widely used in municipal wastewater, mining, chemical filtration, and other industries, with excellent customer reputation. 30Especially their

Widely used in municipal wastewater, mining, chemical filtration, and other industries, with excellent customer reputation. high-strength wear-resistant filter cloth,

Widely used in municipal wastewater, mining, chemical filtration, and other industries, with excellent customer reputation. which not only effectively prevents clogging but also

Widely used in municipal wastewater, mining, chemical filtration, and other industries, with excellent customer reputation. improves filtration speed

and reduces maintenance costs, significantly increasing production efficiency!4. After choosing the filter cloth, how to use and maintain it correctly?Buying high-quality filter cloth is important, but correct usage and maintenance are also crucial! The following points must be noted👇50%,Reduce maintenance costs and significantly improve production efficiency!

4. How to Properly Use and Maintain the Filter Cloth After Selection?

After purchasing a high-quality filter cloth, proper usage and maintenance are crucial! Pay close attention to the following key points:👇

✅ Step 1: The filter cloth must be tightly attached to the filter plate without any wrinkles, otherwise it will affect the sealing and filtration efficiency.

✅ Step 2: Clean the filter cloth once before use to remove surface impurities and improve initial filtration effect.

✅ Step 3: Regularly check the filter cloth for damage. If small holes or cracks are found, replace it as soon as possible to avoid solid particles entering the filtrate.

✅ Step 4: After each filtration, clean the filter cloth in a timely manner to avoid blockage caused by residual filter cake.

✅ Step 5: When storing the filter cloth, keep it in a dry and ventilated environment to avoid mold and aging.

By correctly using and maintaining the filter cloth according to the above methods,it can not only extend the service life of the filter cloth but also keep your plate and frame filter press running efficiently!

V. Conclusion: Choosing the right filter cloth saves money and worry!

The filtration effect of the plate and frame filter press,80%depends on the filter cloth.If you are still troubled by low filtration efficiency, filter cloth blockage, high moisture content in the filter cake, it may be time to change to a filter cloth that truly suits you!

Years of industry experience, specializing in manufacturing industrial filter clothsefficient and durable plate and frame filter press filter cloth,Filter cloth, withhigh permeability, wear resistance, anti-blocking, and long service life, has helped thousands of enterprises solve the filtration problems of plate and frame filter presses. If you want to improve filtration efficiency and reduce operating costs, you might as well try this professional-grade filter cloth!

📞 Consult now +86 13950107241, get a professional selection plan!

💡 Make solid-liquid separation more efficient and production smoother!

Have you also encountered the problem of low filtration efficiency? How effective is the filter cloth you are using? Feel free to share your experiences in the comments!📩