Filter Press Filter Cloth Used in Alumina Refinery Processes

Share to

Detailed Description

The critical role of industrial filter cloths in alumina filtration systems —— The Science Behind Efficient Separation “ The Unsung Hero ”

In the numerous process flows within the chemical industry, solid-liquid separation has always been an indispensable step—especially in Aluminum Oxide Production Process In the process—from bauxite leaching and red mud separation to seed crystal washing—each stage places extremely high demands on the performance of filtration equipment and filter cloths. As a crucial component of the solid-liquid separation system, “ Core Materials ”, Matching and Optimization of Industrial Filter Cloth with Filter Press Equipment , directly determining the filtration accuracy, energy consumption levels, and economic benefits of alumina production.

I. Filtration Nodes in the Alumina Production Process

Aluminum oxide is typically prepared using the Bayer process. Bayer Process ), the process includes several steps such as bauxite crushing, alkali leaching, solid-liquid separation, settling and washing, evaporation-concentration, and crystallization-roasting. In this intricate process chain, Filtration and Separation At least spanning three core stages:

- Red Mud Separation : Separating the leachate from the red mud solid residue is one of the most critical solid-liquid separation steps in the entire process, typically accomplished using a vacuum belt filter or a pressure filter.

- Crystal seed washing During the alumina crystallization stage, multiple washing and filtration steps are required for the aluminum hydroxide seed to ensure product purity and particle uniformity.

- Mother Liquor Purification : Filtering out impurities from the circulating mother liquor is also an important step in enhancing the system's operational stability.

In these processes, the performance of the filter cloth affects the filtration speed, the moisture content of the filter cake, the cleaning efficiency, and the equipment's operational cycle. The filter cloth is not just a piece of material—it is also the key to system efficiency and cost-effectiveness. “ Control Valve ”。

II. The Evolution of Filter Press Equipment Applications in Alumina Plants

In the past, the alumina industry primarily relied on settling ponds and conventional filter presses for red mud separation. However, with increasing environmental pressures and rising production demands, Mechanized, Continuous Filtration Equipment Gradually replacing traditional techniques, the filtration equipment commonly used in the alumina industry today primarily includes:

- Horizontal Vacuum Belt Filter Machine HVBF ) : Suitable for continuous dewatering of high-viscosity materials such as red mud slurry, featuring high filtration efficiency and a high degree of automation.

- Vertical Pressure Filter : Commonly used in the crystal seed washing process, it occupies a small footprint and enables high-pressure dewatering.

- Box-type filter press / Plate-and-frame filter press : Suitable for the fine filtration stage, yielding a drier filter cake and clear filtrate.

While the performance of the equipment is certainly important, what truly determines the filtration effect is the配套 system that works alongside it. Filter Cloth Selection and Process Matching A suitable filter cloth can significantly reduce equipment operating resistance, extend the cleaning cycle, and enhance the clarity of the filtrate.

III. Engineering Requirements for Filter Cloth Performance

The characteristics of alumina slurry are High alkalinity ( pH The value can reach 13 The above) 、 High temperature 60~90℃ ) 、 The particles are fine and exhibit a certain degree of stickiness. Therefore, the filter cloth material and structure must meet the following key requirements:

- Excellent alkali and temperature resistance

Ordinary polyester materials are prone to hydrolytic degradation in high-alkali environments; therefore, in the alumina filtration process, it is common to select Polypropylene PP ) or polyamide ( PA )Monofilament filter cloth . These two materials exhibit high stability under strong alkaline and high-temperature conditions and are not prone to embrittlement. - The filter cake exhibits strong peelability and excellent regeneration performance.

Red mud or seed crystal filter cakes often exhibit a certain degree of stickiness, and if the filter cloth surface is too rough, it can lead to cake adhesion, thereby affecting both cake release and cleaning efficiency.

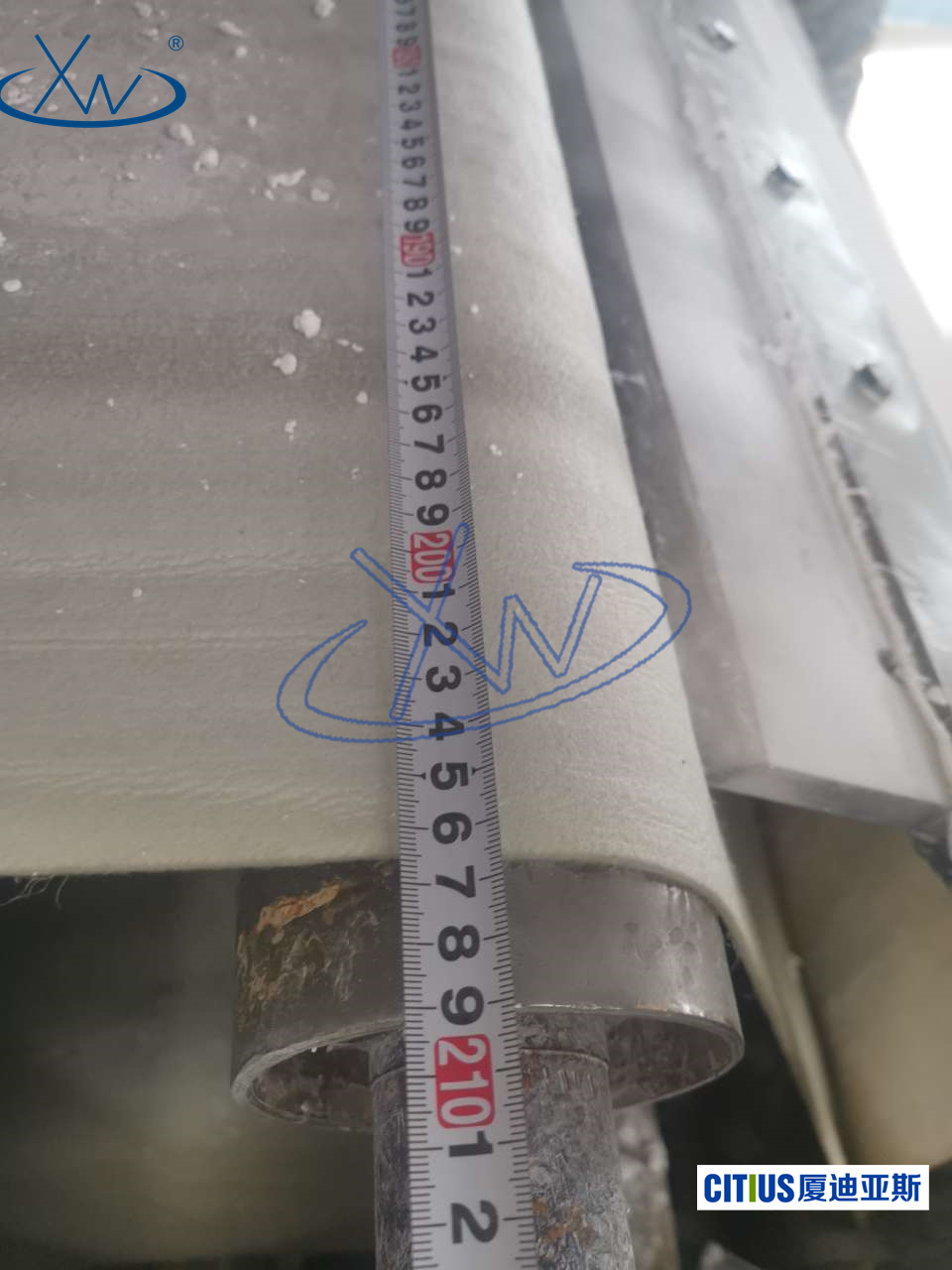

For this, Xiamen Xiadias CITIUS ( CITIUS ) Employing precision weaving and surface finishing technologies, such as heat-setting calendering, surface coating, and anti-clogging coatings, ensures that the filter cloth maintains its strength while also exhibiting excellent cake-release properties. - High air permeability with a stable pore structure

The pore size distribution of the filter cloth directly determines both the filtration rate and the clarity of the filtrate. Xadias CITIUS By employing multi-layer composite weaving combined with imported warp preparation machine control technology, the pore size distribution is made more uniform, thereby achieving High-throughput, low-residue rate The filtering effect. - Dimensionally stable and wear-resistant design

During the frequent pressing, tensioning, and rinsing processes of the filter press, the filter cloth must exhibit excellent dimensional stability and mechanical strength. By employing advanced manufacturing techniques such as imported monofilaments, directionally reinforced edge stitching, and hot-melt splicing, the service life of the filter cloth can be significantly extended.

4. Xadias CITIUS Solutions for alumina filtration systems

With over 30 Years of industrial filtration experience, Xiamen Xiadias CITIUS Filter Materials Technology Corporation Xiamen Citius Filter Media Technology Co., Ltd. ) Providing global alumina plants with comprehensive optimization services for filter cloth design to the entire press filtration system Integrated Solution 。

Typical applications of its filter cloth products in the alumina industry include:

- Red Mud Separation : Utilizing high-strength monofilament filter cloth with an imported double-layer weaving structure, it boasts high air permeability and excellent alkali resistance.

- Crystal seed washing : Utilizing fine-denier monofilament filter cloth ensures that crystal seed particles are not lost, while simultaneously enabling rapid dewatering and clear liquid recovery.

- Mother Liquor Purification : Equipped with high-precision microporous filter cloth, ideal for efficiently capturing suspended particles in recirculation systems.

Xadiaas CITIUS The engineering team can customize filter cloths based on the slurry characteristics of different process sections (such as solid content, particle size distribution, temperature, and alkalinity), including Gluing, punching holes, edging, and alkali-resistant coating Customized processing tailored to help customers achieve optimal filtration performance and operational efficiency.

V. Filtration Innovation Amidst the Green Transition

Currently, the alumina industry is facing “ Dual-Carbon Strategy ” The pressure to transition toward energy conservation and consumption reduction. Efficient solid-liquid separation not only impacts production capacity but also directly affects the environmental burden associated with tailings management and recycled water systems.

Xadiaas CITIUS Currently promoting Low-energy-consumption, high-recovery-rate filter cloth system Research and promotion, for example:

- Nanometer-scale surface modification technology : By plasma treatment and micro-pore structure optimization, we achieve lower-resistance fluid channels.

- Regenerative Filter Cloth Material : Recyclable synthetic fibers that extend service life and reduce waste emissions.

- In conjunction with the new nanomicro-powder filtration system : In the filtration of fine aluminum hydroxide particles, further enhance separation accuracy and product purity.

This technological innovation not only enhances the stability of the filtration system but also aligns with chemical enterprises' needs for Green production, sustainable operations, and cost optimization The long-term goal.

VI. Conclusion: From Filter Cloth to Systems—Building a Future of Efficient Filtration

In the alumina chemical plant, filter cloths may seem unassuming, yet they determine the performance of the entire filtration system. “ Breathing rhythm ” It undertakes every separation and purification process—from pulp to clear liquid, and from coarse particles to fine powder.

As new materials technology, equipment automation, and intelligent control continue to advance, industrial filter cloths are no longer merely consumables—they have become integral components of chemical filtration systems. Engineered, optimized, and upgradeable modular units 。

Xiamen Xadias CITIUS , as a leading brand in China's industrial filtration industry, is currently leveraging 30 Years of technological expertise have brought more efficient, stable, and environmentally friendly solid-liquid separation solutions to the alumina industry.

In the future, from red mud separation to aluminum hydroxide washing, and then to nanometer-level purification filtration, The innovative integration of filter cloths and equipment , will become a significant force in driving the green upgrade of the alumina industry.