Paper mill pulp dewatering filter cloth | Industrial filter cloth for belt press filter

Share to

Detailed Description

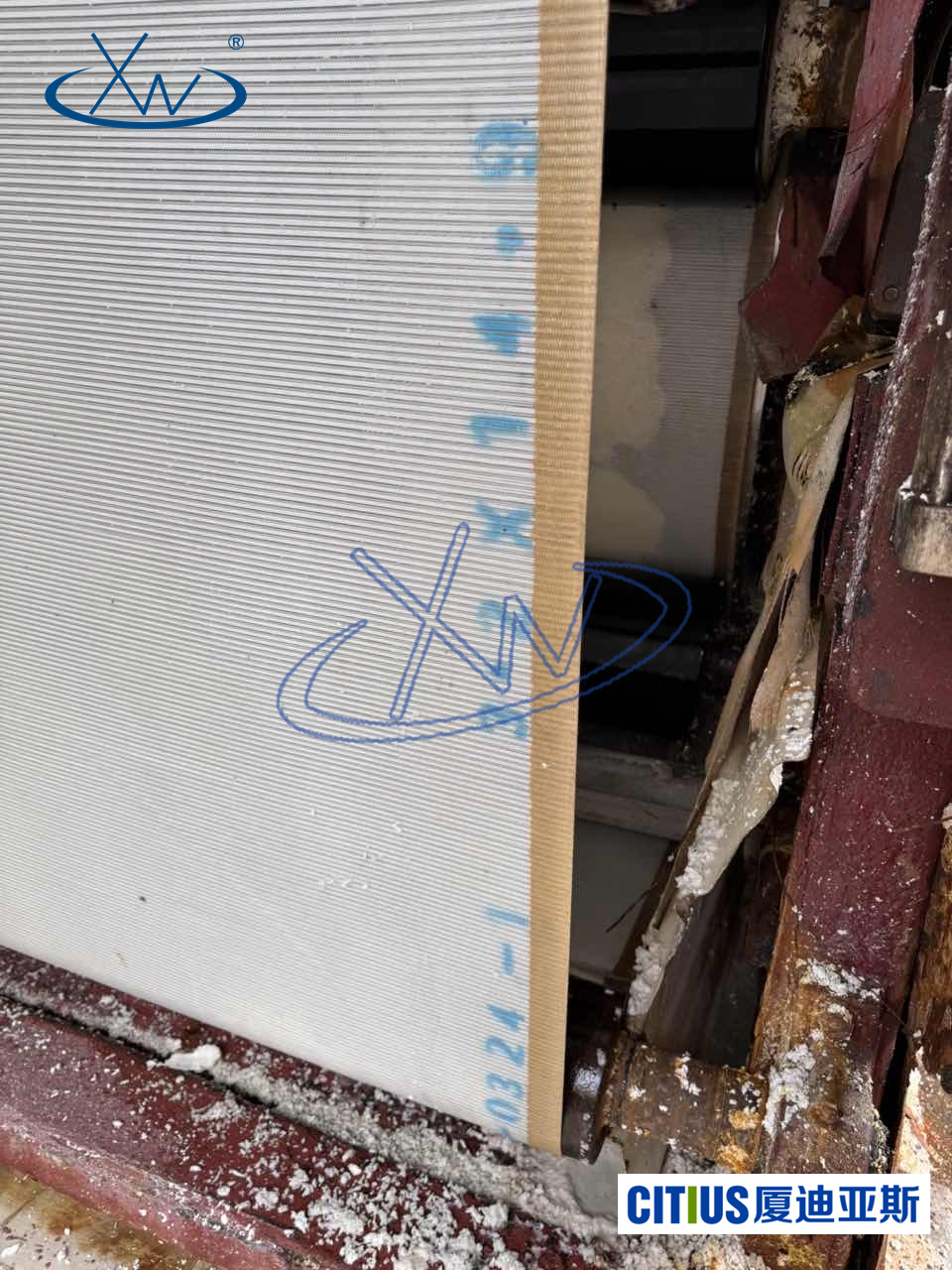

Pulp Dewatering Filter Fabrics for Paper Mills | Industrial Filter Fabric Solutions for Belt Press Filter Machines

In modern papermaking, pulp dewatering is a crucial step in paper formation. It determines not only the moisture content and drying energy consumption of the product, but also affects production efficiency and paper quality. In this process, the filter fabric, as the core functional component of the belt press filter machine, directly determines the operational stability and economy of the dewatering system.

I. Process Requirements and Challenges of Pulp Dewatering

Common raw materials in paper mills include wood pulp, bamboo pulp, grass pulp, and recycled pulp. After pretreatment, washing, and pulping, these pulps usually have a moisture content as high as 95% above, and must be pre-concentrated through effective dewatering methods.

Belt press filter machines have become one of the mainstream equipment, due to the following advantages:

- Continuous operation, high processing capacity ;

- Low energy consumption, compact structure, easy maintenance ;

- High pressing efficiency, pulp can be dewatered to 40-50% dryness ;

- Gentle dewatering process, which is beneficial for fiber protection and maintaining paper strength 。

However, this process also faces a series of challenges:

- The pulp is viscous, the particles are fine, and it is easy to clog the filter fabric;

- It contains a large amount of fine fibers and inorganic fillers, requiring extremely high wear resistance of the filter fabric;

- Continuous high-pressure extrusion operation requires the filter fabric to have extremely strong tensile strength;

- Frequent changes in operating conditions require stable and reliable filtration accuracy and permeability of the filter fabric.

This puts higher demands on filter fabric materials, weaving processes, and surface treatment technologies.

II. Functional Positioning of Filter Fabrics in Belt Press Filter Machines

In the operating system of a belt press filter machine, the filter fabric (also known as a mesh belt or filter belt) is not only a carrier for pulp dewatering, but also undertakes multiple tasks such as conveying, supporting, filtering, and separating filter cakes.

An ideal pulp dewatering filter fabric should have the following key properties:

1. Excellent dewatering efficiency

The structure of the filter fabric determines the number and distribution of water filtration channels. A filter fabric with a gradient pore size design can quickly remove free water in the initial pressing stage and effectively discharge capillary water in subsequent pressing, significantly improving the pulp dryness.

2. Excellent anti-clogging performance

To prevent fine fibers in the pulp from clogging the filter fabric channels, anti-clogging coatings and special post-treatments are used to enhance its self-cleaning ability.

3. High strength and wear resistance

Because belt filter machines operate continuously, the filter fabric must withstand reciprocating tensile forces and high-pressure roller squeezing, so it must have excellent tensile strength and wear resistance.

4. Stable dimensions and good run-off control performance

The width of the filter fabric ranges from 1 meters to 4 meters, and the length is tens of meters. Dimensional stability directly affects the operation of the entire machine's tension and centering system. The processing of the filter fabric's side seams, guide bars, and rubber edges must be highly precise to prevent run-off and edge lifting.

5. Good filter cake release and regeneration ability

The filter cake after pulp dewatering needs to be quickly separated from the surface of the filter fabric. Severe adhesion will affect the operating efficiency and even cause shutdown for cleaning. Therefore, the surface of high-quality filter fabrics usually has low adhesion and good cleanability.

III. Xiamen Citius | Papermaking Filter Fabric System Solutions

As a national high-tech enterprise in the field of industrial filtration technology textiles, Xiamen Citius Filter Media Technology Co., Ltd. has been deeply involved in the industrial filter fabric industry for 30 years. It has developed a number of high-performance belt press filter fabrics for the papermaking industry, which are widely used in the dewatering treatment of cultural paper, packaging paper, tissue paper, and recycled pulp.

IV. Application Cases and On-site Feedback

In many large papermaking bases in Fujian, Shandong, Zhejiang, and Guangdong, Citius filter fabrics have successfully served dozens of large paper companies. Some case summaries:

- A packaging paper mill with an annual output of 50 ten thousand tons using our filter fabrics, the cake dryness increased by 8% and the dewatering efficiency increased by 12%;

- A tissue paper company used our low-resistance filter fabrics for high-fines pulp dewatering, solving the problems of serious clogging and frequent shutdowns of the original filter fabrics;

- A recycled pulp processing project for environmental protection using a new high-strength pressing filter fabric, the moisture content of the filter cake was reduced from 68% to 52%。

Customers generally feedback that our filter fabrics are stable in operation, smooth in cake release, have a long service life, and low maintenance costs, with high overall operating cost-effectiveness.

Conclusion

The efficiency of pulp dewatering is closely related to the performance of the filter fabric. Choosing a highly adaptable, durable, and high-efficiency industrial filter fabric is the key to improving papermaking capacity, reducing energy consumption, and ensuring product quality. Citius will continue to cultivate and improve in technology, products, and services to provide strong support for the green development of the global papermaking industry.

- Pulp Dewatering Filter Fabrics for Paper Mills | Belt Press Filter Machine Industrial Filter Fabrics

Filter Machine Type: Belt Press Filter Machine

Application Industry: Papermaking

Material Handling Description: Pulp Dewatering

Filter Cloth Model: 055R04