Paper mill chemical mechanical pulp dewatering filter cloth | Industrial filter cloth for belt press filter

Share to

Detailed Description

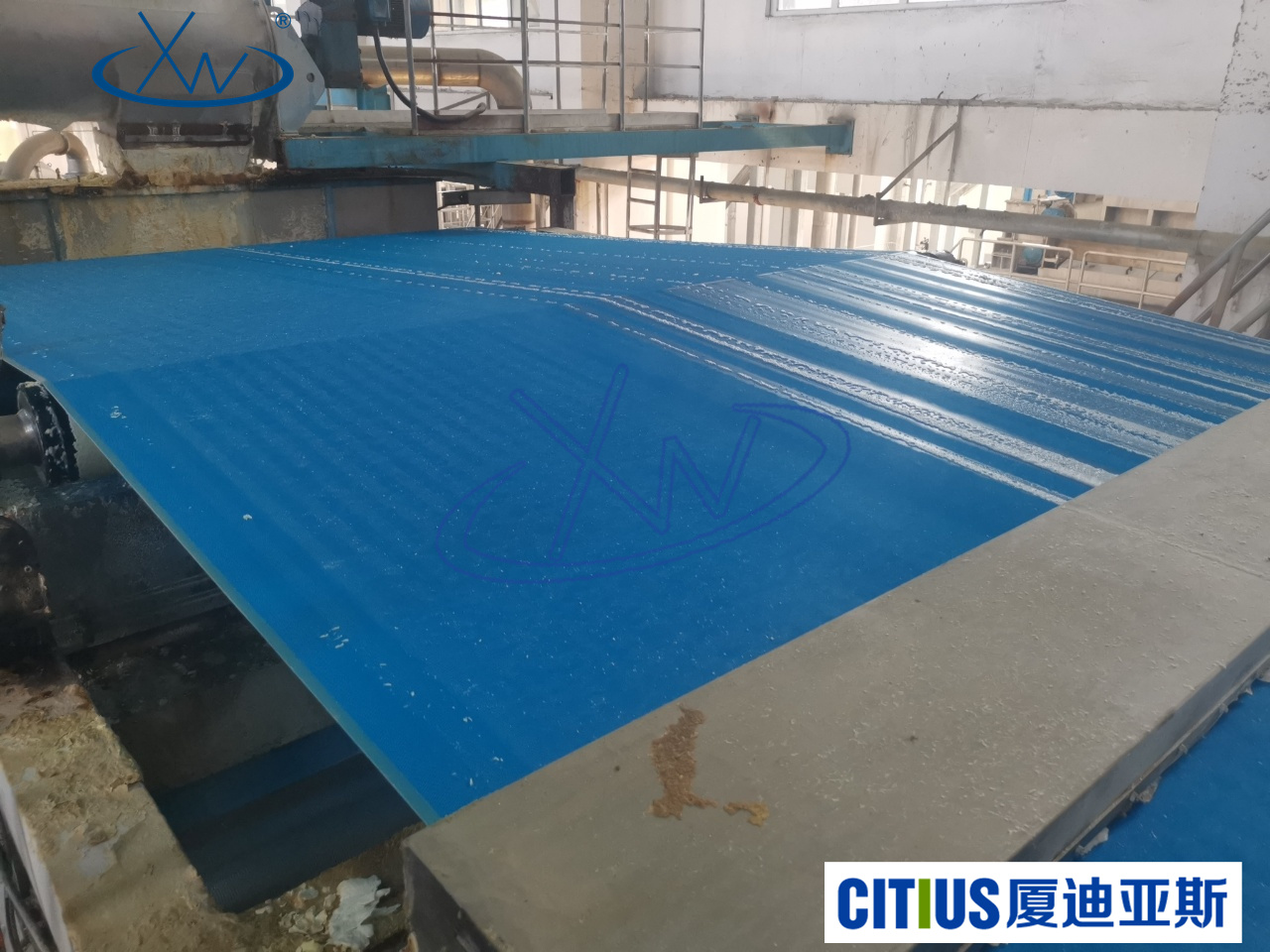

Paper Mill Chemical Mechanical Pulp Dewatering Filter Cloth | Industrial Filter Cloth Solutions for Belt Press Filter Machines

In modern papermaking industry, chemical mechanical pulp (CMP) 'Chemical Mechanical Pulp' as a key raw material connecting the performance of chemical pulp and mechanical pulp, its preparation process puts higher standards on equipment, process parameters and material configuration. Especially in dewatering how to achieve effective separation of fine fibers and colloidal substances is a core factor determining the quality, energy consumption and subsequent pulping efficiency of CMP. In dewatering equipment, belt press filter machines are widely used due to their continuous and efficient characteristics, and the key component supporting their stable operation — industrial filter cloth, has become the technical core that determines the system performance.

This article will focus on: the particularity of chemical mechanical pulp dewatering, the matching requirements of belt press filter machines, the structure, performance and technical parameters of filter cloth, and Xiamen Xiadiasi's engineering practice and innovative solutions to provide the industry with a systematic and forward-looking filter cloth application guide.

I. Chemical Mechanical Pulp: Both " delicate ” and " troublesome ” pulp type

Chemical mechanical pulp (CMP) uses chemical pretreatment + combined with mechanical grinding, removing some lignin while retaining fiber length, making the fibers have good softness and binding force, widely used in the production of newsprint, cultural paper, packaging paper, etc. However, this type of pulp shows a series of complex characteristics during the dewatering process:

- Short fibers, containing a large number of cell fragments and colloidal particles ;

- High pulp viscosity, low free water content difficult to remove by traditional mechanical methods;

- Uneven filter cake formation during dewatering, easy to produce interlayer water content difference ;

- Residual chemicals in the pulp pose a risk of corrosion and fatigue to the filter material 。

Therefore, the dewatering equipment must not only have high-pressure pressing performance, but also needs to be matched with high-matching industrial filter cloth to complete effective interception, separation and clear liquid export.

II. Belt Press Filter Machine: Ideal Carrier for Continuous Dewatering Equipment

Belt press filter machines are widely used in the concentration and dewatering systems of paper pulp due to their good dewatering efficiency and adaptability. Its working principle is based on multi-roller pressing, gravity and capillary suction, removing free water and some bound water from the pulp to form a preliminary dry pulp.

In the CMP process, this equipment faces the following technical challenges:

- Extremely high compressive strength and stability requirements for filter cloth to avoid compression deformation;

- Good dewatering rate and filter cake separation performance are required to ensure the running rhythm;

- Must have high self-cleaning ability to cope with the high viscosity and high clogging tendency of the pulp;

- The filter cloth must maintain dimensional stability and cyclic wear resistance under high tension 。

Therefore, the filter cloth is not simply a filtration medium, but a structure, performance, and material synergistic " high-precision fabric ”。

III. Design Points of Industrial Filter Cloth: Tailor-made Solutions for CMP

1. Multi-layer structure, gradient filtration

The CMP dedicated filter cloth developed by Xiadiasi adopts double-layer or multi-layer composite structure design :

- The surface layer is finely woven, effectively intercepting fine fibers and impurities;

- The middle layer has hollow transition channels, strong guiding performance, and enhanced dewatering rate;

- The bottom layer is a high-strength support layer, providing structural stability and tensile performance.

2. Anti-clogging design, enhanced permeability

Because chemical mechanical pulp contains a large number of small colloids and cell fragments, our filter cloth introduces:

- Special materials to improve surface lubricity;

- Low surface energy coating treatment effectively inhibits particle adhesion;

- Heat setting process stabilizes the pore structure and reduces burr clogging.

IV. Xiamen Xiadiasi: Expert in Papermaking Filter Cloth Solutions

As a standard drafting unit and national high-tech enterprise Xiamen Xiadiasi has more than 30 years of technical accumulation, serving more than 1,000 paper industry customers, covering various sub-scenarios such as cultural paper, life paper, and packaging paper.

- In the field of CMP dewatering, we continuously optimize filter cloth design and formulas through a series of engineering practices, building a complete set of customized solutions oriented to customer operating conditions.

Conclusion: Industrial filter cloth, a bridge connecting pulp and the future

The dewatering process of chemical mechanical pulp is a comprehensive challenge " filter cloth ” is a comprehensive challenge; the application of high-performance filter cloth is an important guarantee for stable production and green manufacturing of enterprises. Choosing the right filter cloth is not just choosing a piece of fabric, but also choosing a systematic filtration efficiency solution.

Xia Dia Si is willing to be your most trustworthy partner in the papermaking dewatering process, contributing professional strength to the efficient dewatering of every ton of pulp.

- Filter cloth for chemical mechanical pulp dewatering in paper mills | Industrial filter cloth for belt press filter

Filter type: Belt press filter

Application industry: Papermaking

Material description: Chemical mechanical pulp

Filter cloth model: 002A