Industrial filter cloth for horizontal vacuum belt filter - filter cloth for calcium phosphate filtration

Share to

Detailed Description

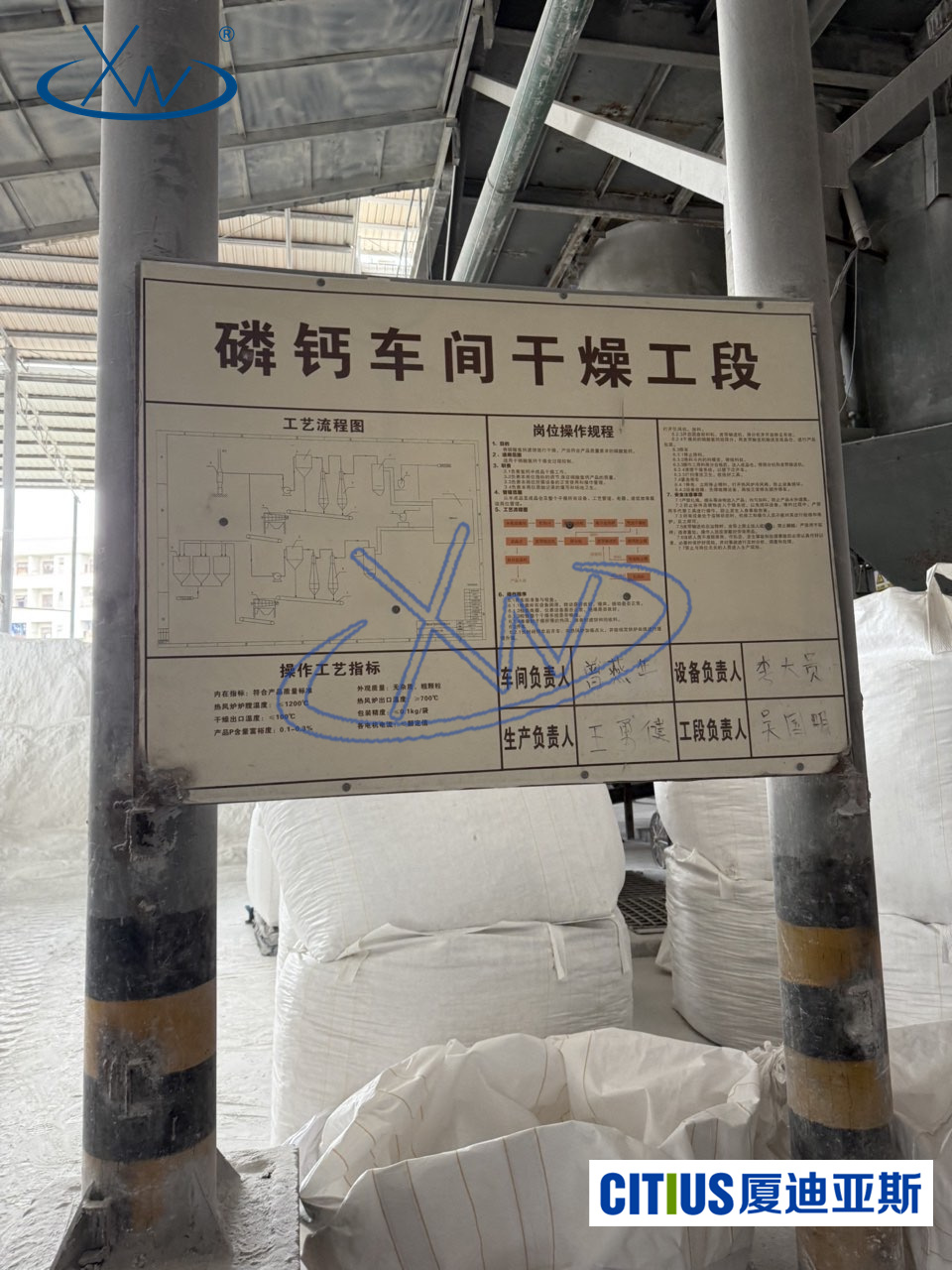

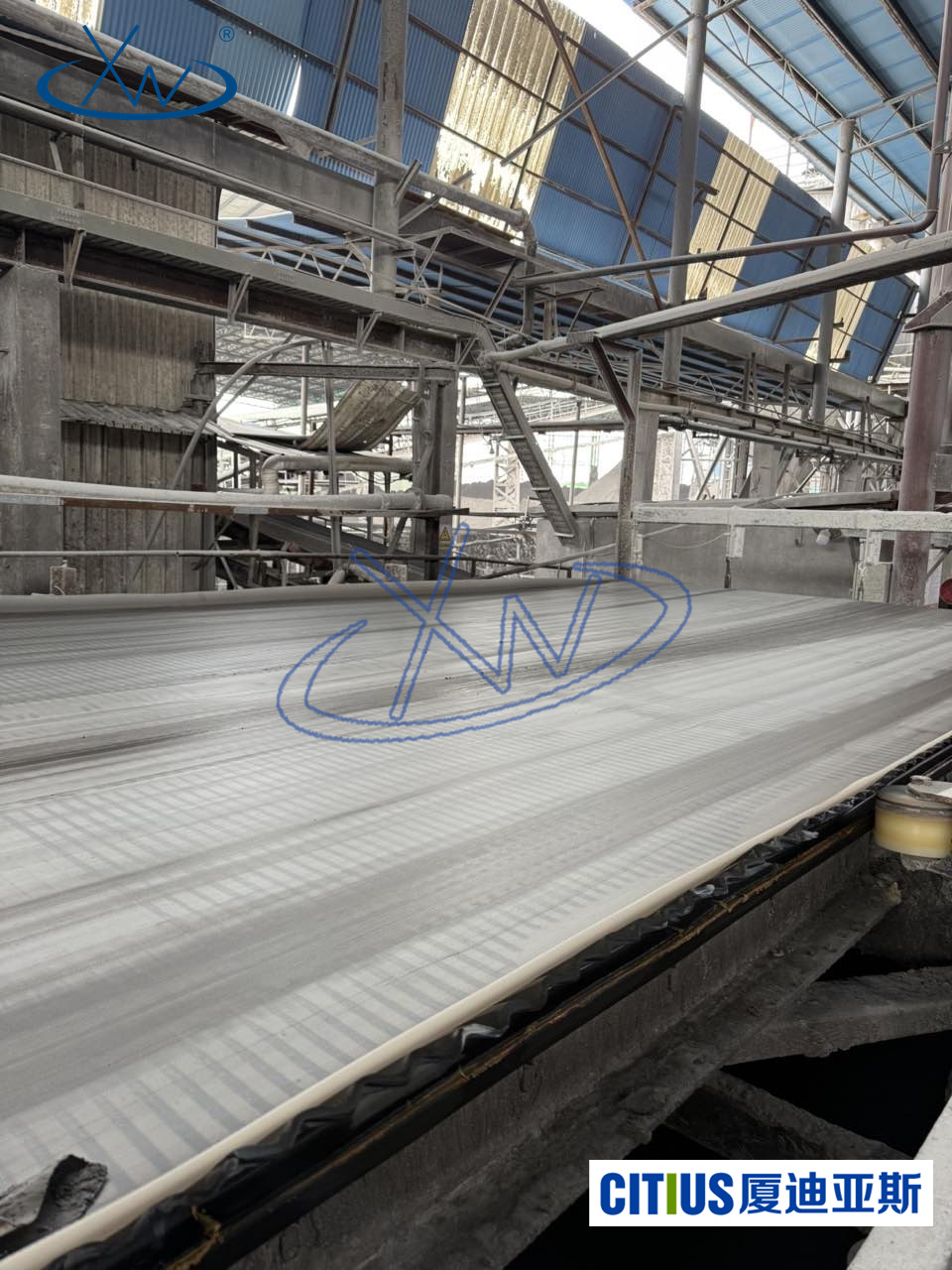

Industrial filter cloth for horizontal vacuum belt filter —— Special solutions for calcium phosphate filtration

In the phosphoric chemical industry chain, calcium phosphate, as an important intermediate product or byproduct, is widely present in various process stages such as wet phosphoric acid production, phosphate ore flotation, and calcium-containing wastewater treatment. The solid-liquid separation process of calcium phosphate places high demands on equipment and filter media: it must have good dehydration efficiency, anti-blocking properties, corrosion resistance, and continuous stable operation. Horizontal vacuum belt filter ( HVBF ) combined with special industrial filter cloth has become an ideal process combination for handling calcium phosphate slurry.

I. Industry background and challenges of calcium phosphate filtration

Calcium phosphate mainly includes:

- Monocalcium phosphate ( MCP )

- Dicalcium phosphate ( DCP )

- Tricalcium phosphate ( TCP )

- and calcium salt impurities in the wet phosphoric acid process

The filtration conditions of these materials generally have the following characteristics:

Project | Characteristic description |

|---|---|

Particle size | D90 Less than 20 microns, easy to block the cloth, difficult to form filter cake |

Slurry viscosity | Contains some unreacted by-salts or colloidal substances, poor fluidity |

Strong acidity | Often accompanied by residual phosphoric acid, sulfuric acid, pH Can be as low as 2~3 |

Easy to scale and crystallize | Secondary crystallization is easy to form on the flow path and filter cloth surface, affecting efficiency |

High environmental requirements | The effluent needs to be clear, and the solid waste needs to be stably discharged |

Therefore, the filter cloth must have a high Corrosion resistance, good permeability, high-strength woven structure and Anti-blocking and easy-to-clean performance 。

II. Process advantages of horizontal vacuum belt filter

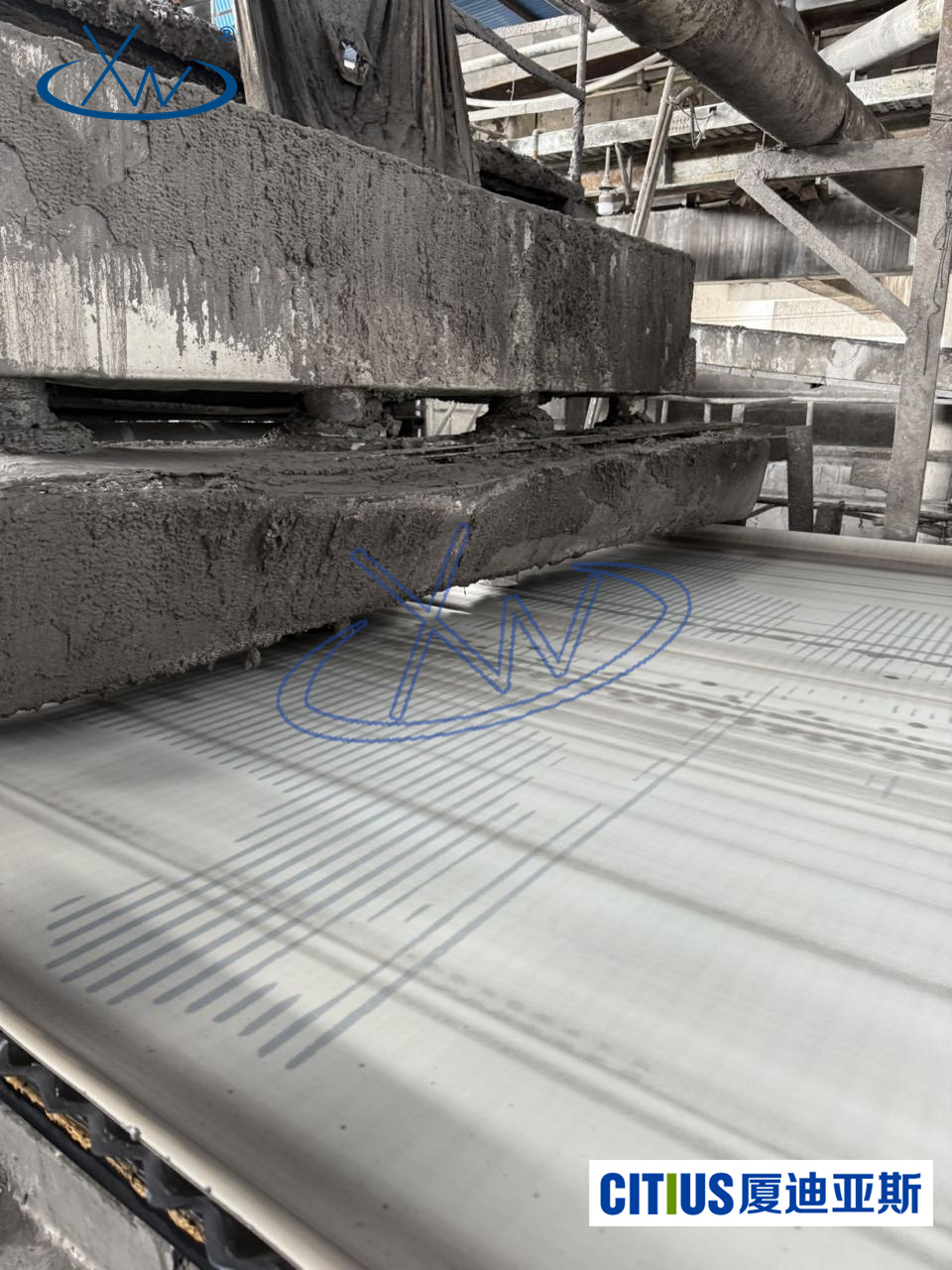

HVBF Because of its Continuous operation, adjustable cloth speed, vacuum section pressure adjustment and other characteristics, it is very suitable for continuous dehydration treatment of medium and high viscosity materials such as calcium phosphate.

Process flow description:

- The slurry is evenly distributed to the surface of the running filter cloth;

- Negative pressure is formed in the vacuum section to achieve rapid solid-liquid separation;

- The filter cake passes through the washing section and the pressing section (optional) in sequence;

- Finally, it is discharged by a scraper or vibration system.

This process requires the filter cloth to effectively support the filter cake dehydration while ensuring the permeability, and to have stable operating tension and peeling performance.

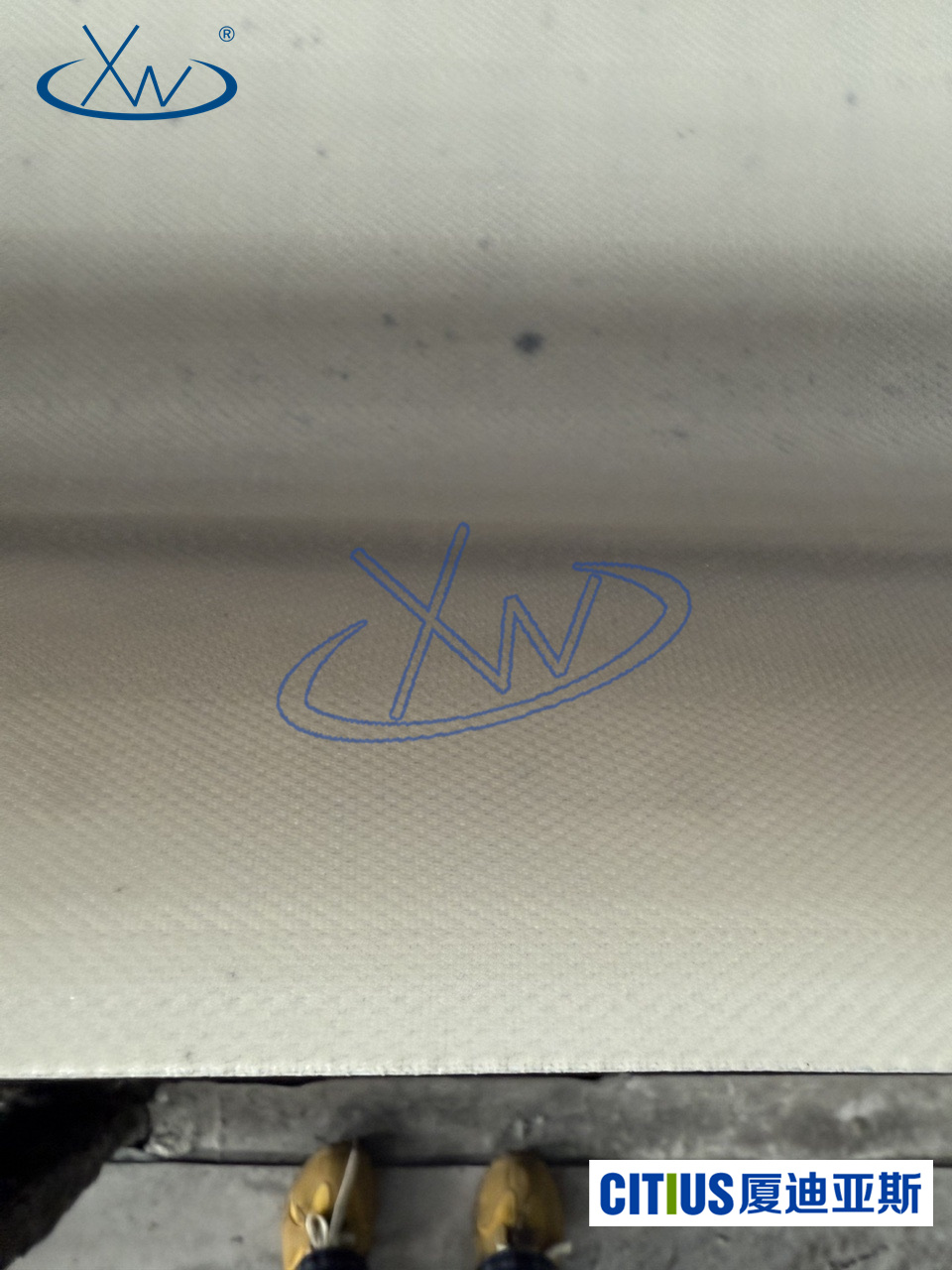

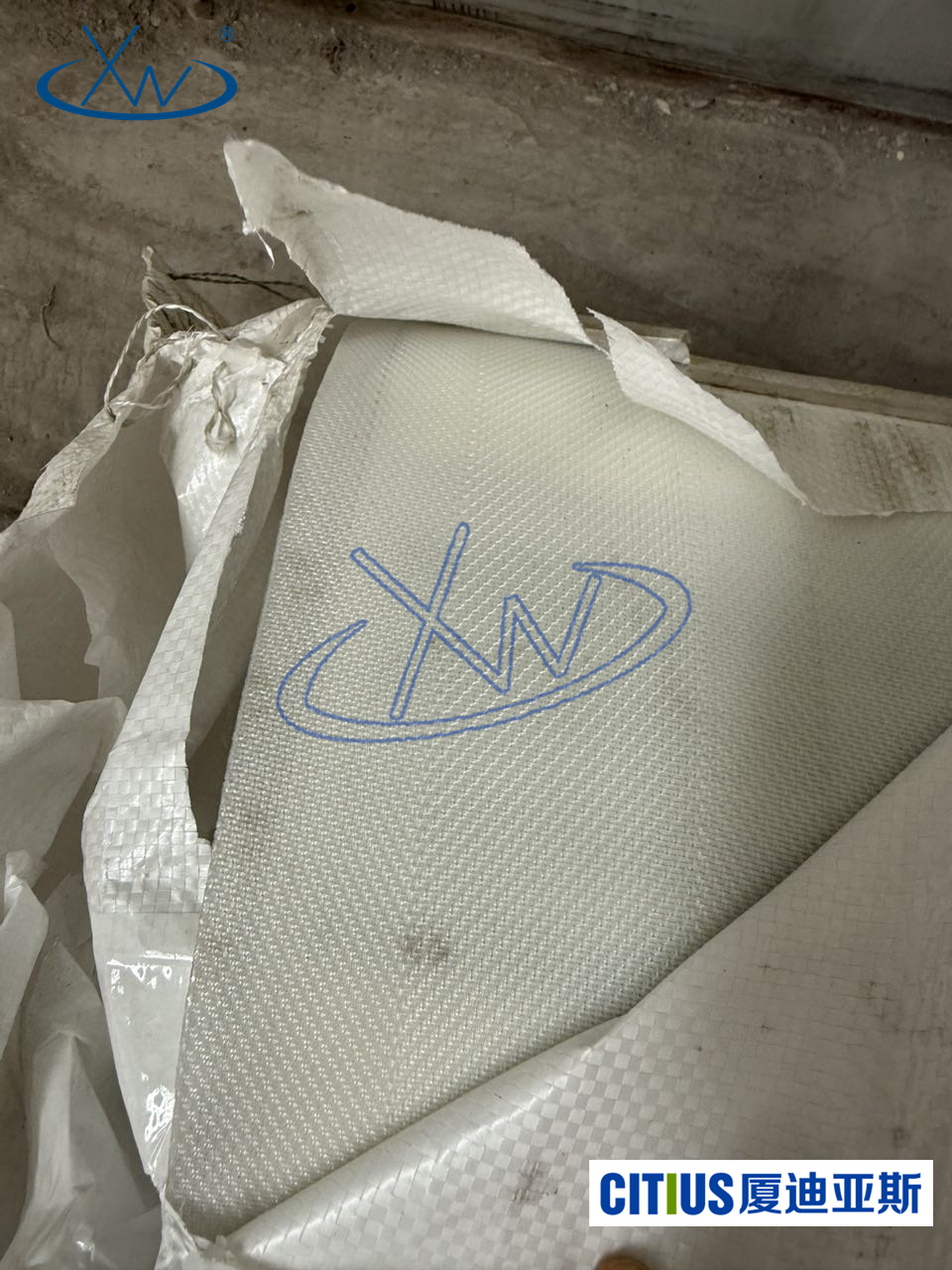

III. Xiamen Xiadias Calcium Phosphate Special Filter Cloth Technical Solution

Xiamen Xiadias Filtration Materials Technology Co., Ltd., focusing on the R&D and manufacturing of high-end filtration materials for 30 years, has developed a series of special filter cloths for horizontal vacuum belt filters for calcium phosphate conditions.

Technical highlights:

- Acid-resistant edging + Heat setting treatment : Improve the edge sealing of the filter cloth in low pH value environment;

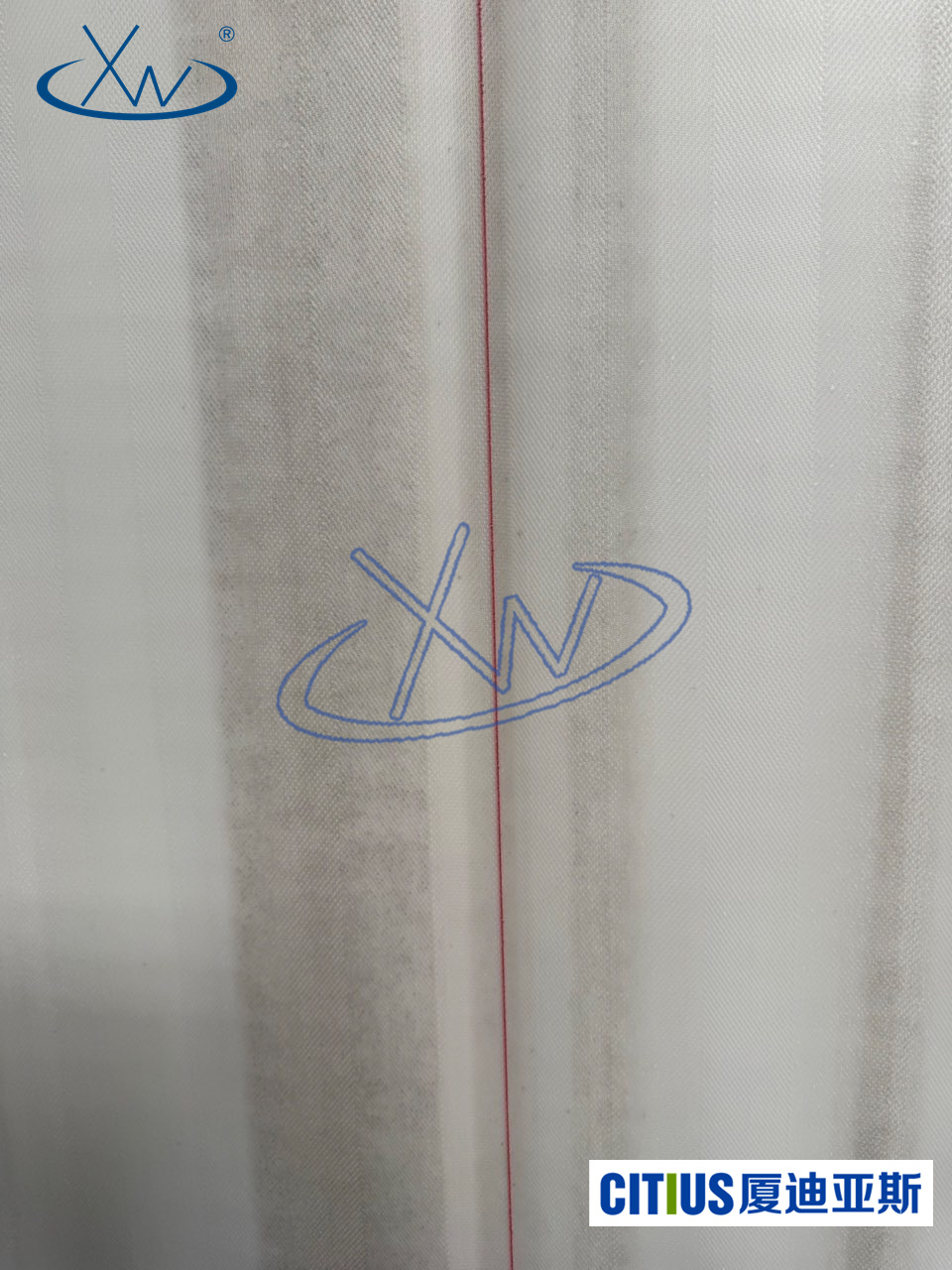

- Self-cleaning structural design : Through miniature diversion weave + Water needle cleaning assistance, reduce cloth area fouling;

- Breathable and filtration accuracy balance design : Conventional air permeability is controlled at 30~60 L/m²/s to ensure that the filtrate is clear and the pressure difference is controllable;

- Wear-resistant track area thickening layer : Adapt to 24 hours of continuous operation of belt filter conditions.

IV. Application effects and customer feedback

Xiadias calcium phosphate special filter cloth has been widely used in the following scenarios:

- Solid-liquid separation of calcium salt by-products in wet phosphoric acid plants

- Concentration and dehydration of calcium-containing residue after phosphate ore flotation

- Fine filtration process of phosphate fertilizer precursors

- Further purification and recovery of calcium-based materials from phosphogypsum

Actual operating data (customer feedback):

- Filter cake moisture content: Reduced to 25~30% which is conducive to subsequent drying or packaging;

- Filtrate turbidity: Less than 15NTU ,basically meets the requirements for recycled water;

- Equipment cleaning frequency: Significantly reduced, average production capacity increased by approximately 20%;

- Filter cloth replacement and operating failure rate have been significantly reduced 。

V. Conclusion: Empowering the green development of the phosphorus chemical industry with professional filter cloth solutions

The filtration of calcium phosphate connects the upstream reaction and downstream purification, drying, and other core processes of phosphorus chemical production. Xiamen Xiadias, relying on its strong R&D platform and application support team, has provided efficient and stable customized filter cloth solutions for many phosphorus-based enterprises, helping customers improve filtration efficiency, reduce comprehensive energy consumption, and achieve the dual goals of clean production and resource recovery.

- Industrial filter cloth for horizontal vacuum belt filter - Filter cloth for calcium phosphate filtration

Filter type: Horizontal vacuum belt filter

Application industry: Calcium phosphate

Material description: Calcium phosphate

Filter cloth model used: 15P