Filter cloth - horizontal vacuum belt filter, vertical filter press | Chemical industry filtration solutions

Share to

Detailed Description

Filter Cloth - Horizontal Vacuum Belt Filter, Vertical Plate Filter Press | Chemical Industry Filtration Solutions

Filter Type: Horizontal Vacuum Belt Filter, Vertical Plate Filter Press

Application Industry: Chemical

Material Description:

1. No. 1 plate Lsx low silicon.

3. No. 3 plate Ny.

4. No. 4 plate 4A-5.

2. No. 2 plate LiLSx lithium low silicon.

5. No. 5 plate 3A.

6. No. 6 plate 4A-5.

7. No. 7 plate 4A.

8. No. 8 plate NaLsx sodium low silicon.

Filter cloth model: 303C, 15p series, 95 type

Application of filter cloth in horizontal vacuum belt filter: Low silicon lithium / Low silicon sodium material filtration solution

In the modern chemical industry, especially in the production of fine chemical materials such as lithium salts, molecular sieves, and zeolite catalysts, the accuracy and efficiency of the solid-liquid separation process play a decisive role in product purity, subsequent drying load, and overall operating costs. Xiamen Citius Filtration Materials Technology Co., Ltd., as an industry leader in the field of filtration material technology fabrics, provides efficient and stable filtration solutions for low-silicon lithium and low-silicon sodium systems in the chemical industry, especially suitable for horizontal vacuum belt filters.

I. Material Characteristics

In this scheme, the materials processed mainly come from different types of chemical reaction mother liquor and precipitation products, including the following typical types:

- 1 Plate Number Lsx Low silicon : A low-silicon type molecular sieve precursor, the material particles are fine and easy to block the cloth;

- 2 Plate Number LiLSx Lithium low silicon : Lithium-containing low-silicon molecular sieve structure, poor fluidity;

- 3 Plate Number Ny : Neutral salt material with strong adhesion, containing some by-product ions;

- 4 Plate Number 4A-5 & 7 Plate Number 4A : Zeolite molecular sieve products, the fine structure after molding has strict requirements on the filter cloth pore size;

- 5 Plate Number 3A : Zeolite type with smaller pore size, high requirements for residual liquid control;

- 8 Plate Number NaLSx Sodium low silicon : Typical sodium-type low-silicon molecular sieve, the material is loose but has high dispersibility.

These materials generally have the following common characteristics:

- Wide particle size distribution of solid-liquid separation particles, high proportion of fine particles;

- Large range of variation in suspension concentration, poor filter cake formability;

- Requires the filter cloth to have excellent air permeability and anti-blocking performance;

- The filter cloth must have good filter cake release ability and chemical corrosion resistance.

II. Equipment and Process Matching: Horizontal Vacuum Belt Filter

Horizontal Vacuum Belt Filter ( Horizontal Vacuum Belt Filter, HVBF ) with its continuous operation, high vacuum filtration, adjustable cloth speed and flexible configuration of the pressing section and other advantages, it has become the ideal equipment for processing this type of material.

Advantages:

- Continuous operation, suitable for large-scale production needs ;

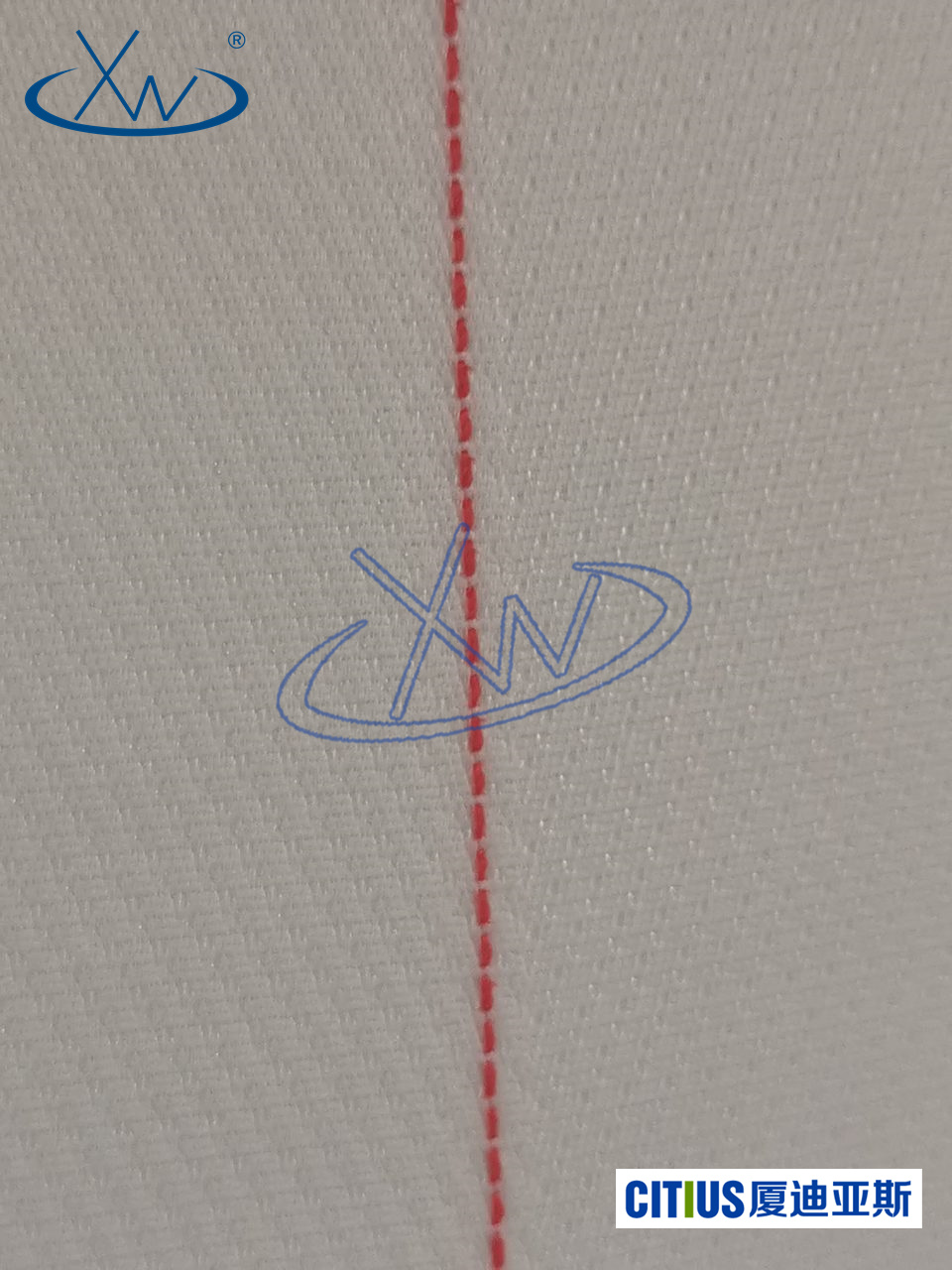

- Stable belt tensioning and track deviation correction system ensures uniform material distribution ;

- Can be equipped with pre-coating system and anti-blocking spray system to effectively cope with the risk of fine particle blockage ;

- Applicable to various filter cloth materials and structures to match materials with different particle sizes and viscosities 。

III. Filter Cloth Selection and Customized Solutions

For the above 8 types of plate materials, Xiadias recommends the following customized filter cloth combination scheme:

Material Number | Main Physical Characteristics | Xiadias Filter Cloth Advantages | |

|---|---|---|---|

1 Number Lsx Low silicon | Fine particles, easy to block | Surface is not easy to paste cloth, good drainage | |

2 Number LiLSx Lithium low silicon | Thin filtrate, strong adhesion | High compressive strength, easy filter cake removal | |

3 Number Ny | High viscosity, many impurities | High clarity of filtrate, extended cleaning cycle | |

4 Number /6 Number 4A-5 | Nanometer-level filter cake | High-precision solid-liquid separation | |

5 Number 3A | Ultrafine powder, filter cake is easy to crack | Smooth surface, reduces filter cake damage | |

7 Number 4A | Evenly dispersed, difficult to dewater | High dehydration rate, less residual liquid | |

8 Number NaLSx Sodium low silicon | Multi-stage reaction products | Strong chemical resistance, not easily degraded |

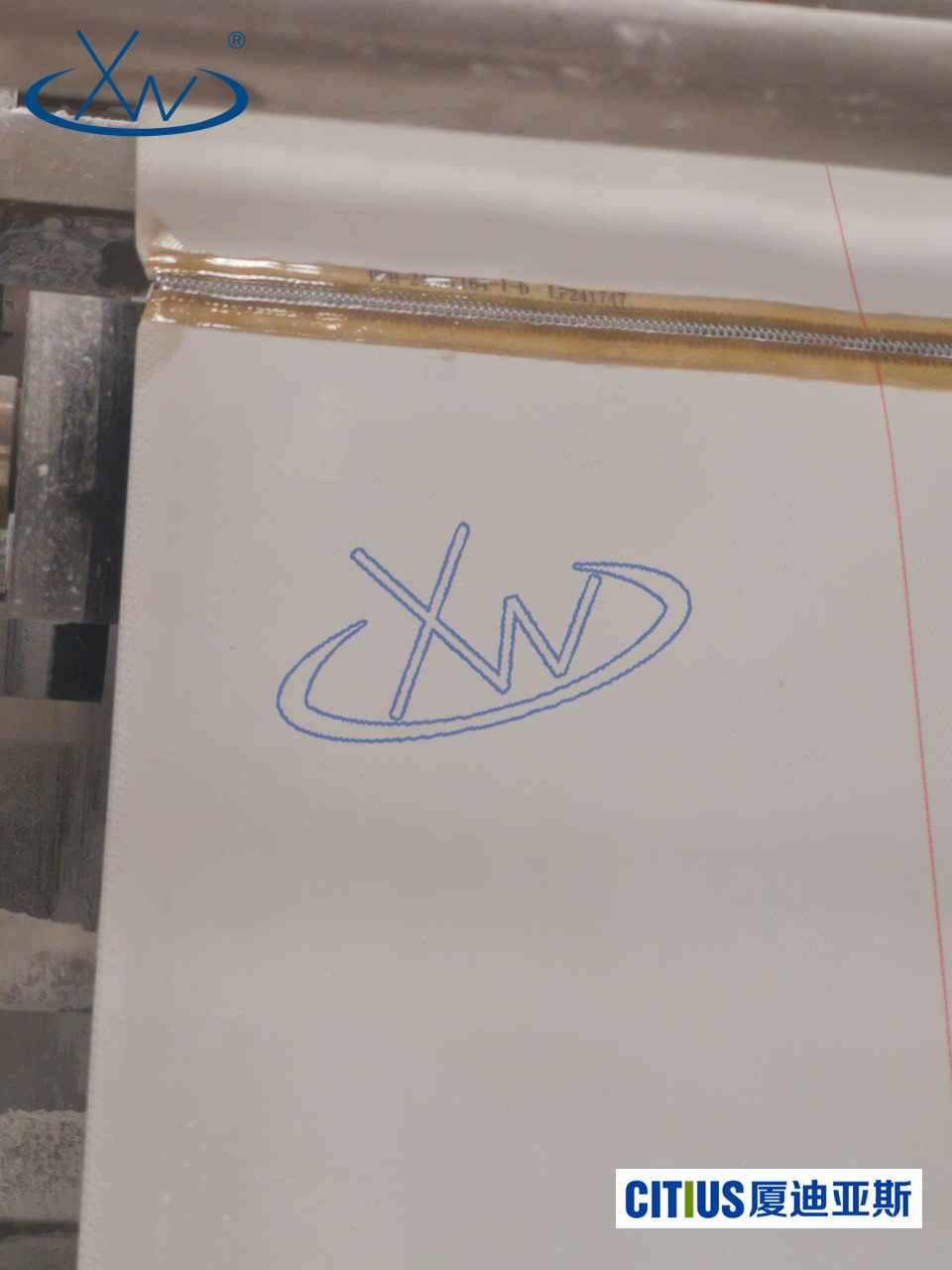

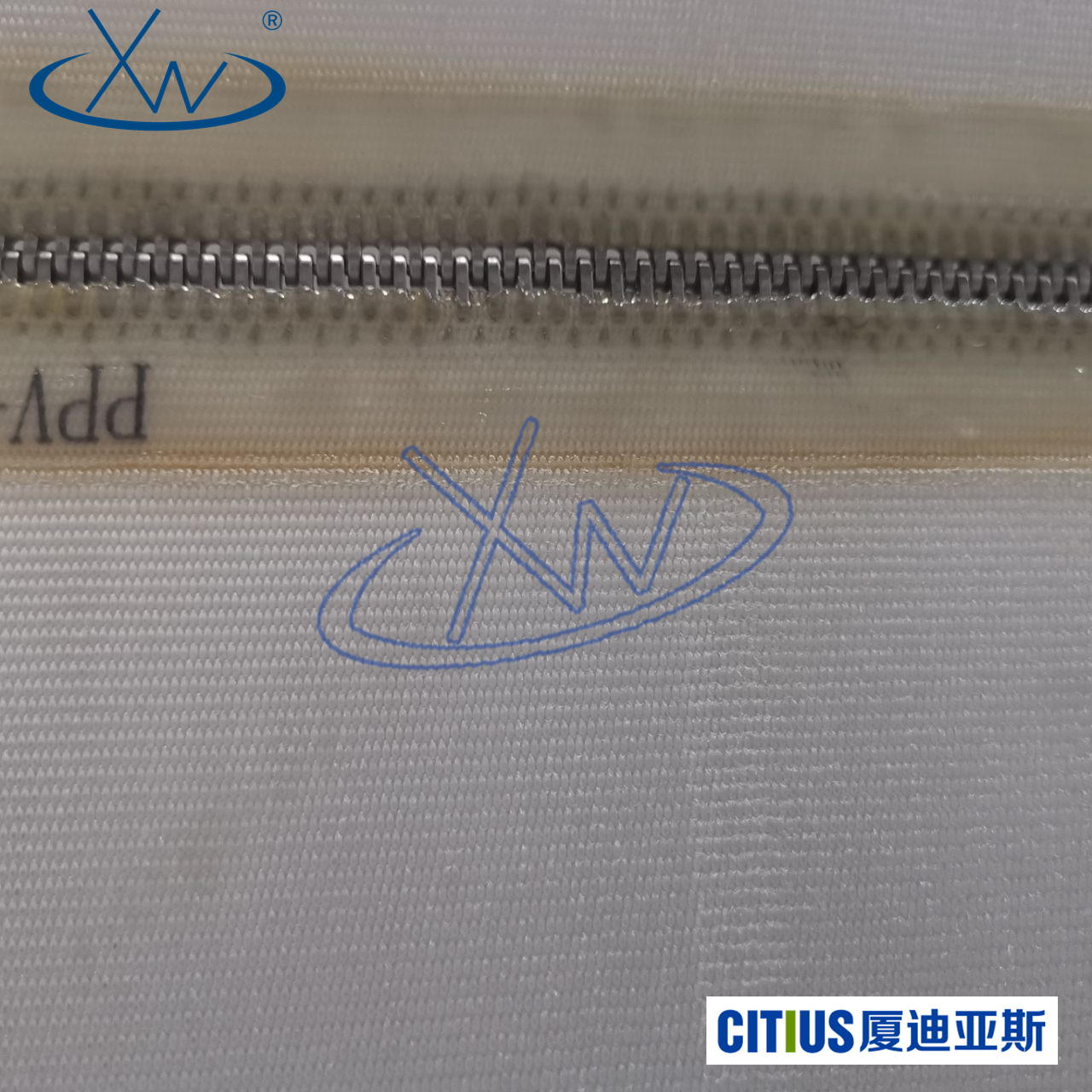

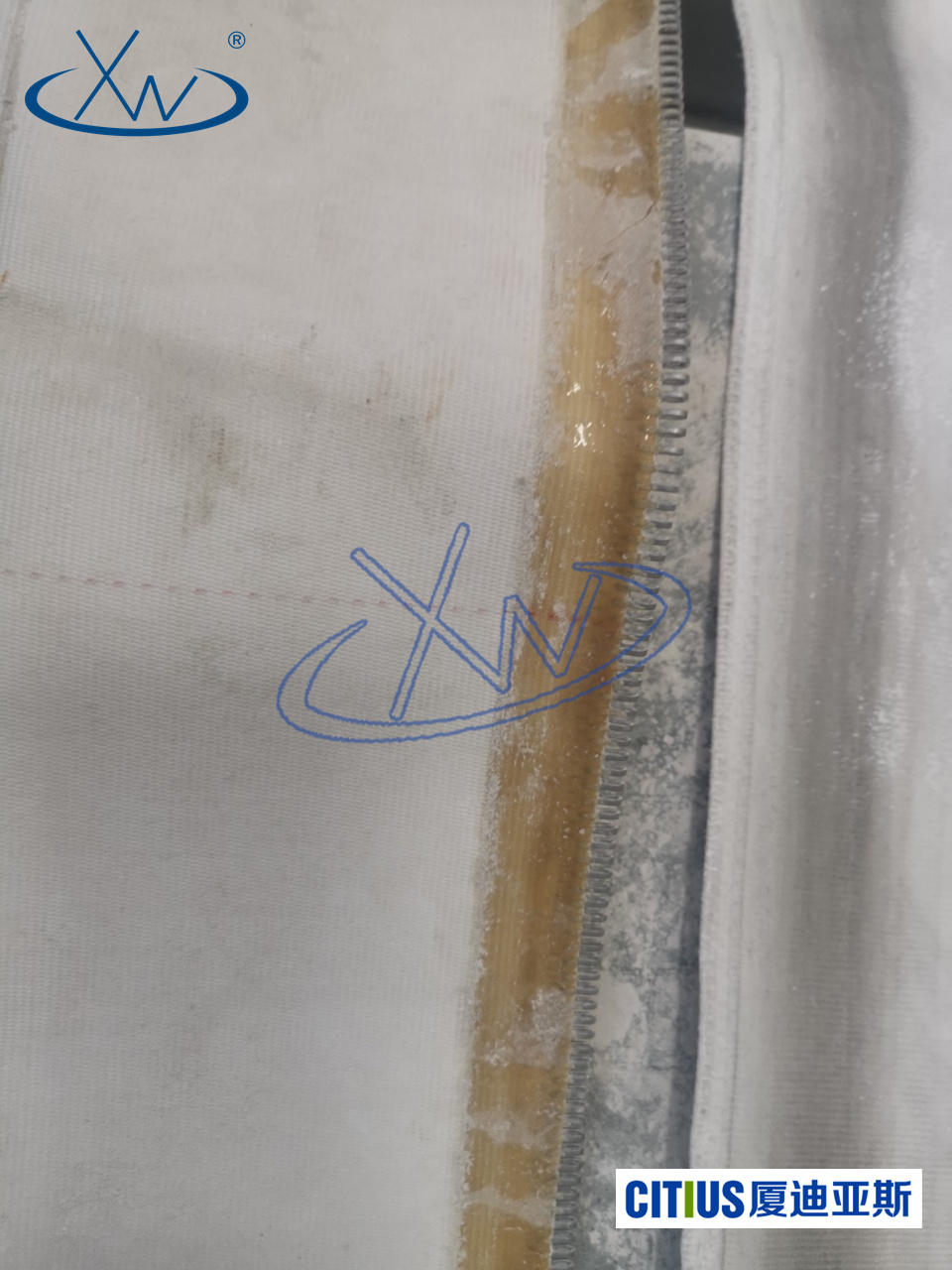

In addition, Xiadias has developed the following supporting technologies for these working conditions:

- Filter cloth anti-blocking surface treatment : Suitable for micrometer-level molecular sieve slurry;

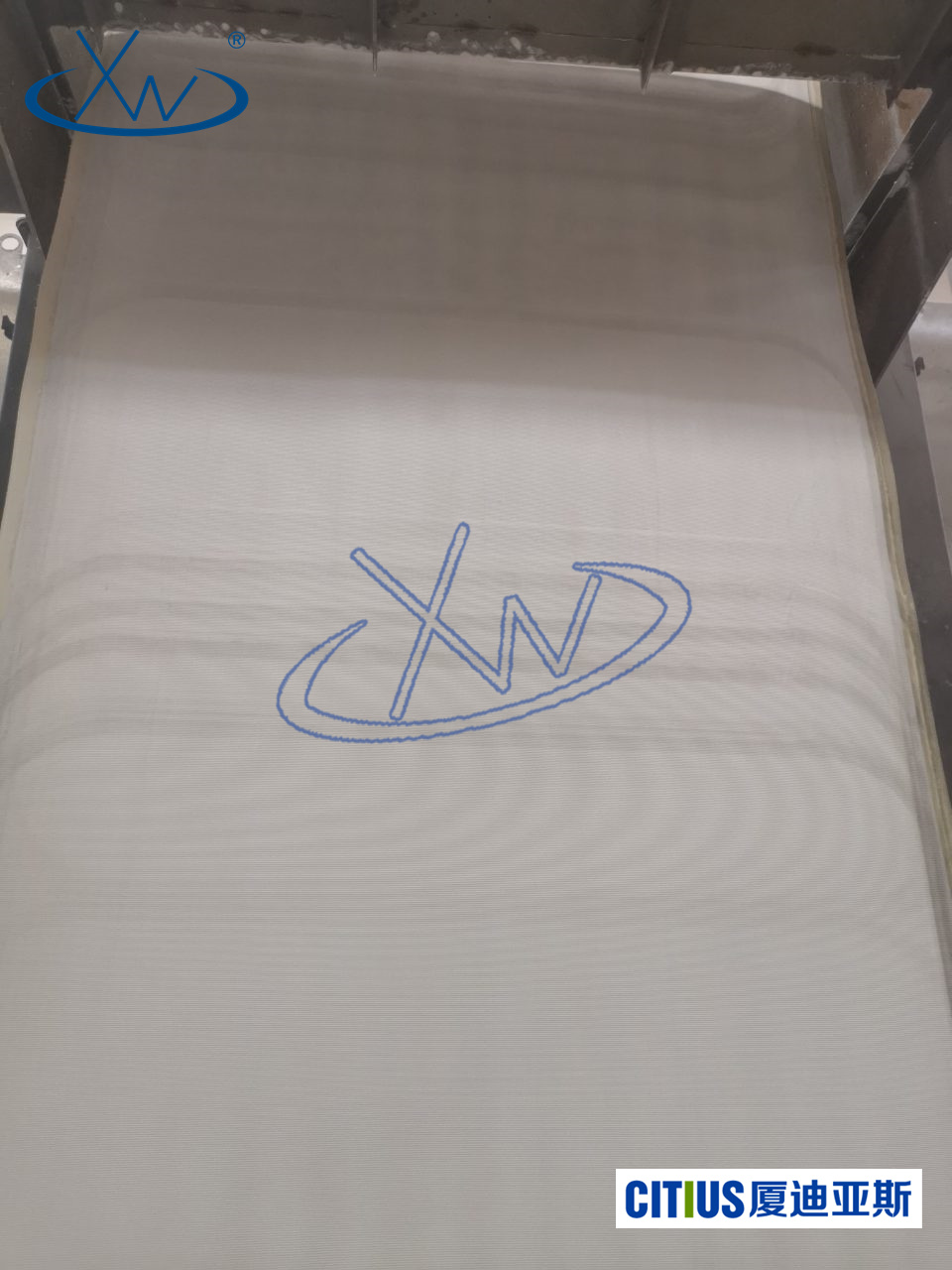

- High permeability edge design : Avoid mud accumulation or wrinkles at the edges of the cloth;

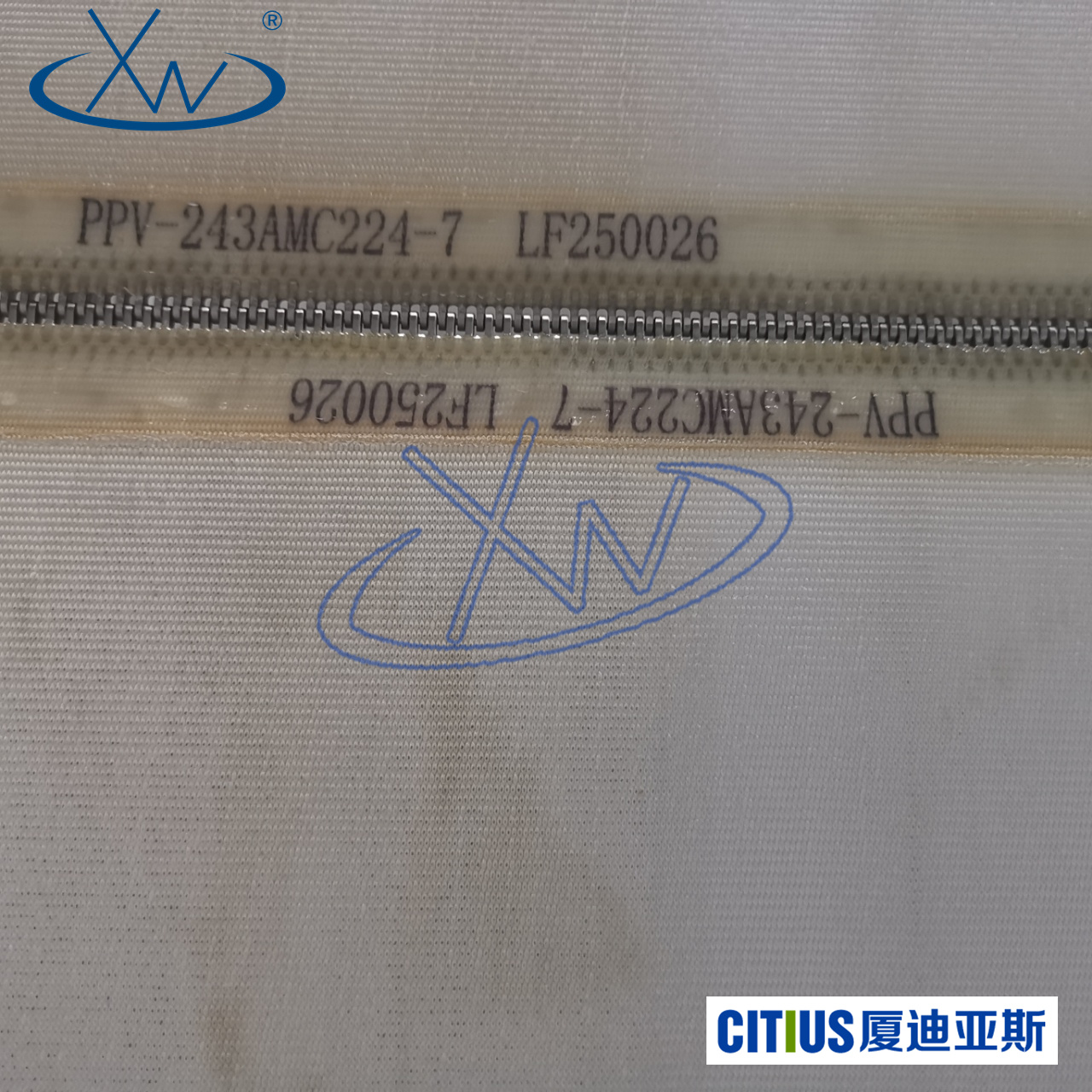

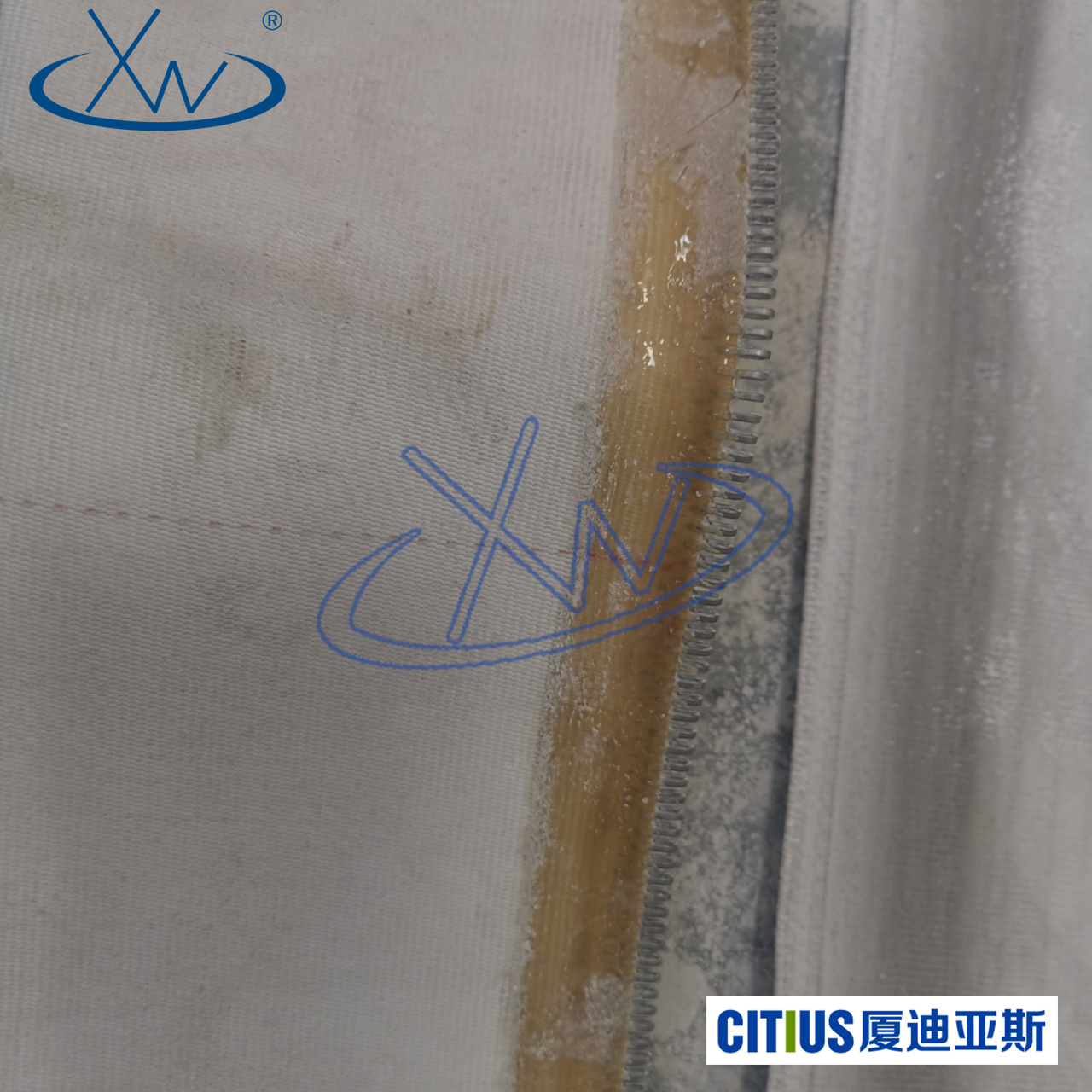

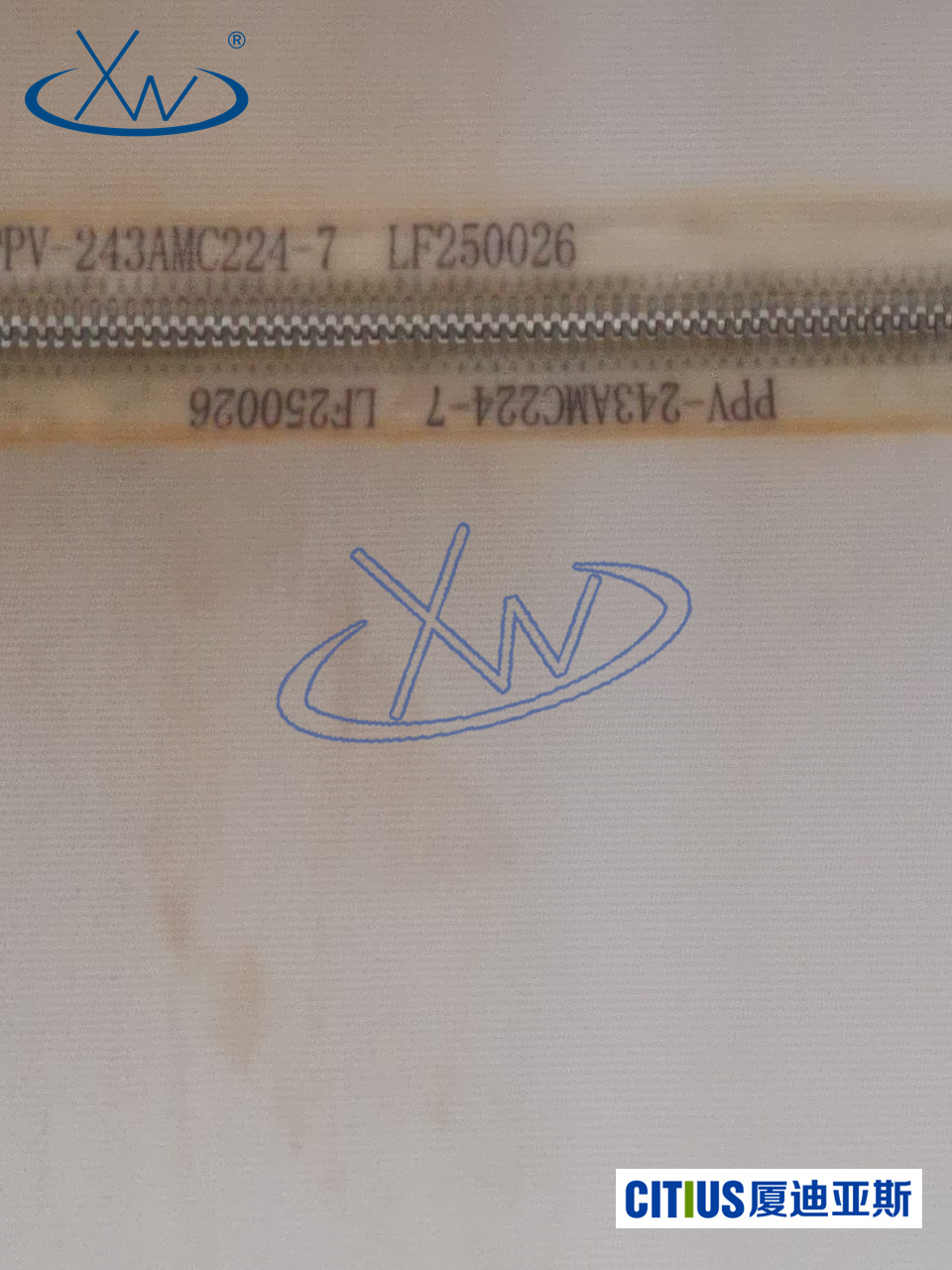

- Glue brushing process to prevent material leakage : Stable filter cloth operation, not easy to shift;

- Alkali-resistant high-temperature edge binding process : Improve the corrosion resistance of the filter cloth edge and extend the service life.

IV. Actual application effects and customer feedback

In the actual application of many molecular sieve and fine chemical plants, this series of filter cloths and HVBF system combination, has achieved:

- Filter cake moisture content is stably controlled at **18~22%** ;

- Filtrate clarity can reach **<20ppm** Suspended solids **;

- Average service life is significantly higher than ordinary filter cloth;

- The cleaning cycle can be extended from the original daily 1 times to weekly 1~2 times, significantly reducing operating and maintenance costs.

V. Conclusion: Providing customized solutions for fine chemical filtration

The filtration needs of low-silicon lithium and low-silicon sodium chemical materials are complex and changeable, putting higher demands on the selection of filter cloths and supporting processes. Citius relies on 30 years of technical accumulation and advanced weaving platform, has provided efficient solutions that have been verified by actual tests for users in multiple industries. Against the backdrop of the rapid development of green chemistry and high-end materials in the future, we will continue to provide customers with professional and personalized filter material support to help achieve more efficient and environmentally friendly production goals.