Tailings Treatment at Mining Sites – Belt Press Filter – Spiral Mesh Belt

Share to

Detailed Description

The Power of Efficient Dehydration —— Application of Spiral Mesh Conveyor Belts in Mine Tailings Treatment

In the vast system of mining production, tailings management is often regarded as “ The final link ” However, it directly impacts a company’s resource recovery rate, environmental safety, and economic efficiency. As environmental policies continue to strengthen and demands for resource utilization rise, how to efficiently dewater and reduce the volume of tailings has become a central issue that mining enterprises are focusing on.

In recent years, belt press filters ( Belt Press Filter )With its continuous, stable, and low-energy-consumption characteristics, it has become essential equipment in the dewatering and solid-liquid separation processes of tailings slurry. And within the entire operational system of the equipment, the spiral mesh belt Spiral Mesh Belt ) As the core medium for filtration and transportation, it plays a decisive role.

I. Challenges in Tailings Treatment and Filtration Requirements

Tailings are fine-grained waste materials left over after ore beneficiation, characterized by high moisture content, fine particle size, and a tendency to cause blockages—they represent a significant challenge in the field of filtration and separation. “ Stubborn Challenge ” While traditional filter presses offer high dewatering rates, they suffer from long cycles, low automation, and a large footprint, making them unsuitable for continuous production. In contrast, belt press filters stand out with Continuous operation, large processing capacity, low energy consumption, and easy maintenance These advantages make it widely applicable for dewatering tailings in fields such as iron ore, copper ore, gold ore, molybdenum ore, lithium ore, and phosphate ore.

However, tailings slurry is characterized by high viscosity and a large proportion of fine particles. If the filter belt performs poorly, it can easily lead to... Problems such as difficult cake detachment, high operational resistance, and filter belt clogging and slippage Therefore, a spiral mesh belt with stable performance and excellent permeability becomes the key to ensuring the equipment's long-term, reliable operation.

II. Structure and Performance Advantages of Spiral Mesh Conveyor Belts

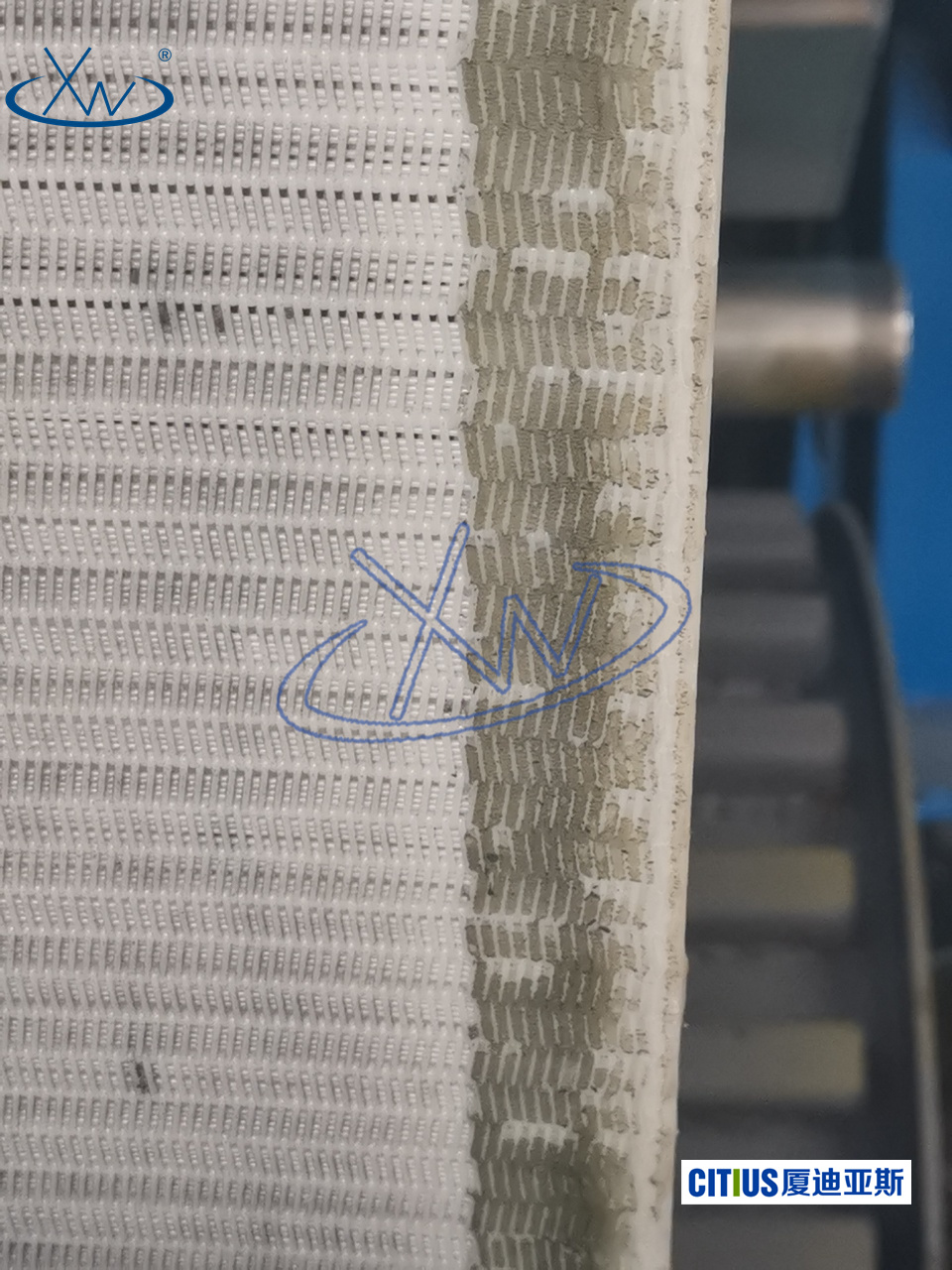

Spiral mesh belt, also known as Helical Link-Type Mesh Belt Spiral Link Mesh Belt ) It is a continuous fabric based on spiral units, interconnected via connecting lines or inserts. Its unique structural design gives it a combination of strength, breathability, and abrasion resistance.

1. High-Strength Structural Design

The spiral mesh is made from high-strength polyester monofilaments, which undergo heat-setting and tension-control processes, giving it… Excellent tensile strength and dimensional stability , it can still maintain stable operation under prolonged high-pressure dehydration conditions and is resistant to deformation.

2. Excellent water permeability and cake-release performance

The mesh belt features a flat, smooth surface with a uniform pore structure, enabling rapid drainage and excellent filter cake release. Compared to traditional filter cloths, the spiral mesh is better suited for the continuous dewatering process of fine-particle materials. Effectively reduces filter cake adhesion and secondary contamination. 。

3. Highly wear- and chemical-resistant

The slurry often contains fine sand, metal ions, and chemical agents. The spiral mesh is made from acid- and alkali-resistant, abrasion-proof polyester or modified materials, which significantly extends the filter belt's service life while reducing replacement frequency and downtime costs.

4. Stable operation, convenient maintenance

Thanks to the interface-free or smooth-joint design, the spiral mesh conveyor belt ensures even stress distribution and stable tension during operation, making it resistant to deviation. Its modular structure allows for quick on-site assembly and easy replacement, significantly reducing maintenance time.

III. Typical Applications in Belt Press Filters

In the tailings treatment system at mining sites, belt press filters typically consist of three stages: a gravity dewatering zone, a wedge-shaped pre-compression zone, and a high-pressure pressing zone. The spiral mesh belt plays a distinct role in each of these stages:

- Gravity Dewatering Zone :The spiral mesh provides excellent support and an initial filtration channel, enabling free drainage of the tailings slurry and forming a filter layer with controllable thickness;

- Wedge-shaped Pre-compression Zone :The filter belt gradually withstands increasing pressure, while the spiral structure ensures more uniform removal of moisture from within the filter cake, preventing material overflow.

- High-pressure squeezing zone Under the action of multi-roll high pressure, the spiral mesh remains flat and maintains its tensile strength without deformation, ensuring that the moisture content of the filter cake is reduced to an ideal range (typically down to as low as 25% The following).

After being dewatered by a spiral mesh belt press filter, the tailings from certain metal mines, coal preparation plants, or non-metallic minerals (such as quartz sand, fluorite, and phosphogypsum) can either be directly stockpiled or transported, enabling dry stacking of tailings or their comprehensive utilization.

IV. Dual Benefits of Energy Conservation and Environmental Protection

Compared to plate-and-frame filter presses, belt press filters, when used with a spiral mesh belt, consume only about [the rest of the sentence is missing in the original text]. 40%-60% , and achieve Continuous dehydration, unattended operation, water-saving circulation 。

In practical applications:

- Water recovery rate can be improved by up to 90% The above ;

- The moisture content of the filter cake is reduced by approximately 5%-10% ;

- Filter belt lifespan extended 30% The above 。

These data mean that the spiral mesh belt is not just a “ Consumables ” Moreover, it is a key component in tailings dewatering systems, playing a vital role in enhancing overall energy efficiency and environmental sustainability.

V. Future Trends: The Fusion of Intelligence and Durability

As intelligent mining and green, low-carbon development accelerate, spiral mesh conveyor belts are moving toward A direction toward advanced composite products featuring higher strength, finer pore sizes, and enhanced thermal and chemical resistance. Development.

The filtration media of the future will not only bear “ Dehydration ” The task will integrate new features such as intelligent monitoring, automatic cleaning, and self-repairing capabilities, providing long-term, stable technical support for the dry tailings disposal system.

Conclusion

The spiral mesh belt, serving as the core component of the belt-type press filter. “ Bloodline ” is becoming an indispensable key material in mining tailings treatment systems.

Its high strength, wear resistance, and stable dewatering performance make the separation of every drop of mineral slurry more efficient and environmentally friendly.

In the context of tailings dry stacking and the era of green mining, the application of spiral mesh conveyor belts is steadily expanding, providing a robust impetus for the sustainable development of the mining industry.

- Mine Tailings Treatment – Belt Press Filter – Spiral Mesh Belt

Filter machine type: Belt press filter

Application Industry: Tailings

Filter cloth model: 055R04