Solid-liquid separation – horizontal vacuum belt filter cloth – phosphate chemical processing of phosphoric acid

Share to

Detailed Description

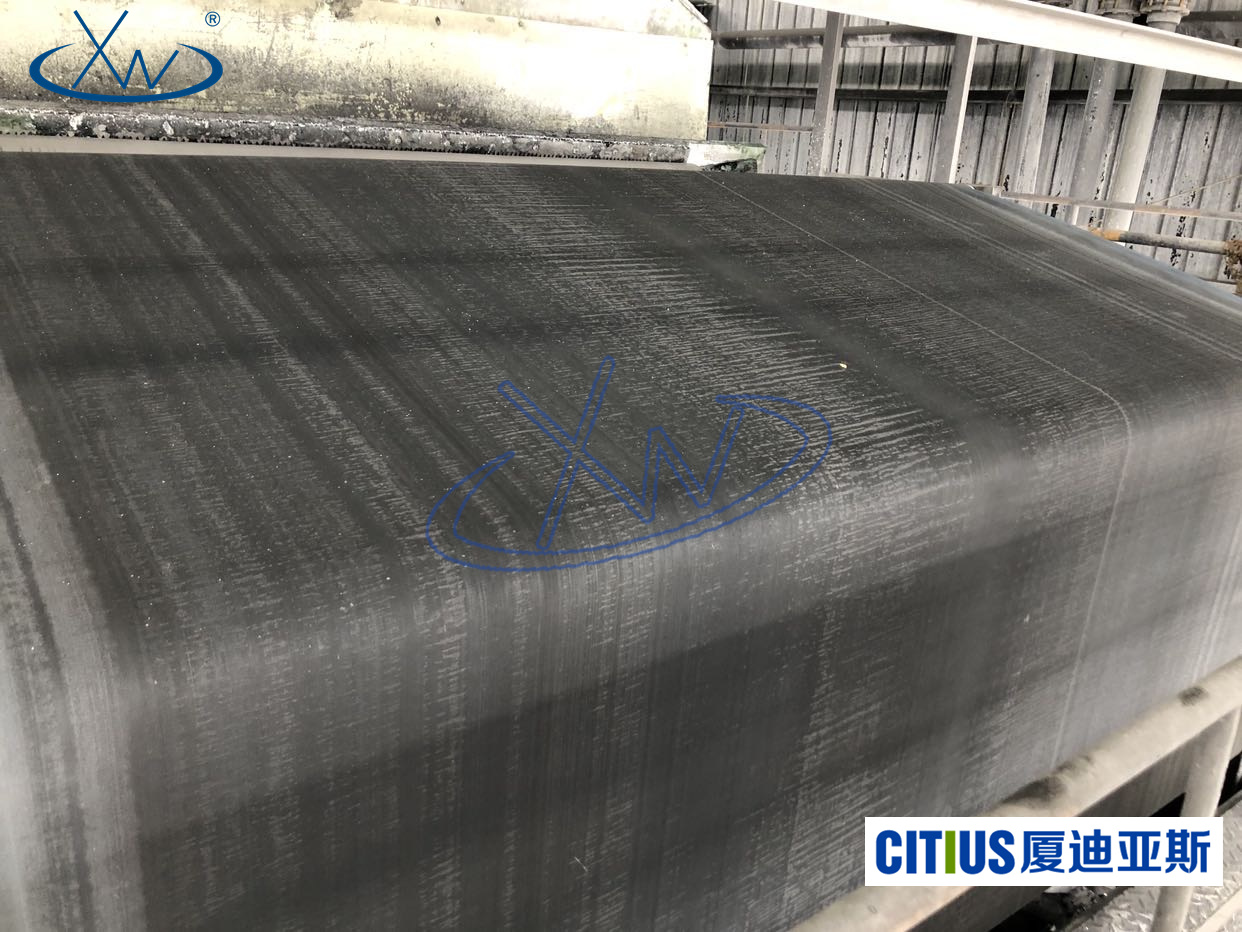

Filtration cloth applications in solid-liquid separation during phosphate chemical phosphoric acid production —— Xadiaas CITIUS Solutions for industrial filter fabrics

In the modern chemical production system, Phosphorus Chemical Industry It is a strategic industry. Whether used in wet-process phosphoric acid for fertilizer production or as a foundational chemical for new materials, pharmaceuticals, and food additives, the purity and efficiency of phosphoric acid directly influence the performance and economic viability of downstream products.

During the wet-process phosphoric acid preparation process, Solid-liquid separation step Particularly crucial, and this is precisely the core scenario where filter cloths and horizontal vacuum belt filters come into play. Xiamen Xiadias CITIUS Filter Materials Technology Corporation (hereinafter referred to as “ Xadiaas CITIUS ) Leveraging over three decades of technological expertise and R&D innovation, we have provided phosphochemical enterprises with high-performance industrial filter cloth solutions, significantly enhancing filtration efficiency and product quality.

I. Challenges in Phosphoric Acid Production and Solid-Liquid Separation

In the wet-process method, after phosphate rock is decomposed by sulfuric acid, it produces Phosphoric slurry containing a large amount of by-products , the main impurities include:

- Gypsum crystals CaSO ₄ · 2H ₂ O )

- Unreacted mineral particles

- Colloidal impurities and organic substances

These solid particles have an uneven particle size distribution and high viscosity. If separation is incomplete, it will not only reduce the purity of the phosphoric acid but also increase energy consumption during subsequent concentration and purification processes. Meanwhile, the acidic components and corrosive impurities in the slurry place extremely stringent demands on the corrosion resistance of both filtration equipment and filter cloths.

Therefore, solid-liquid separation in phosphate production needs to have:

- Continuous and stable operational capability —— Adapt to long-cycle production and reduce downtime maintenance rates;

- High solid-liquid separation efficiency —— Improve phosphate clarity and reduce gypsum residue;

- Corrosion and wear resistance performance —— Ensure the filter cloth can withstand long-term use under strong acid and high-abrasion conditions;

- Renewability and Cost-effectiveness —— The filter cloth should have excellent cleaning and regeneration properties to reduce overall operating costs.

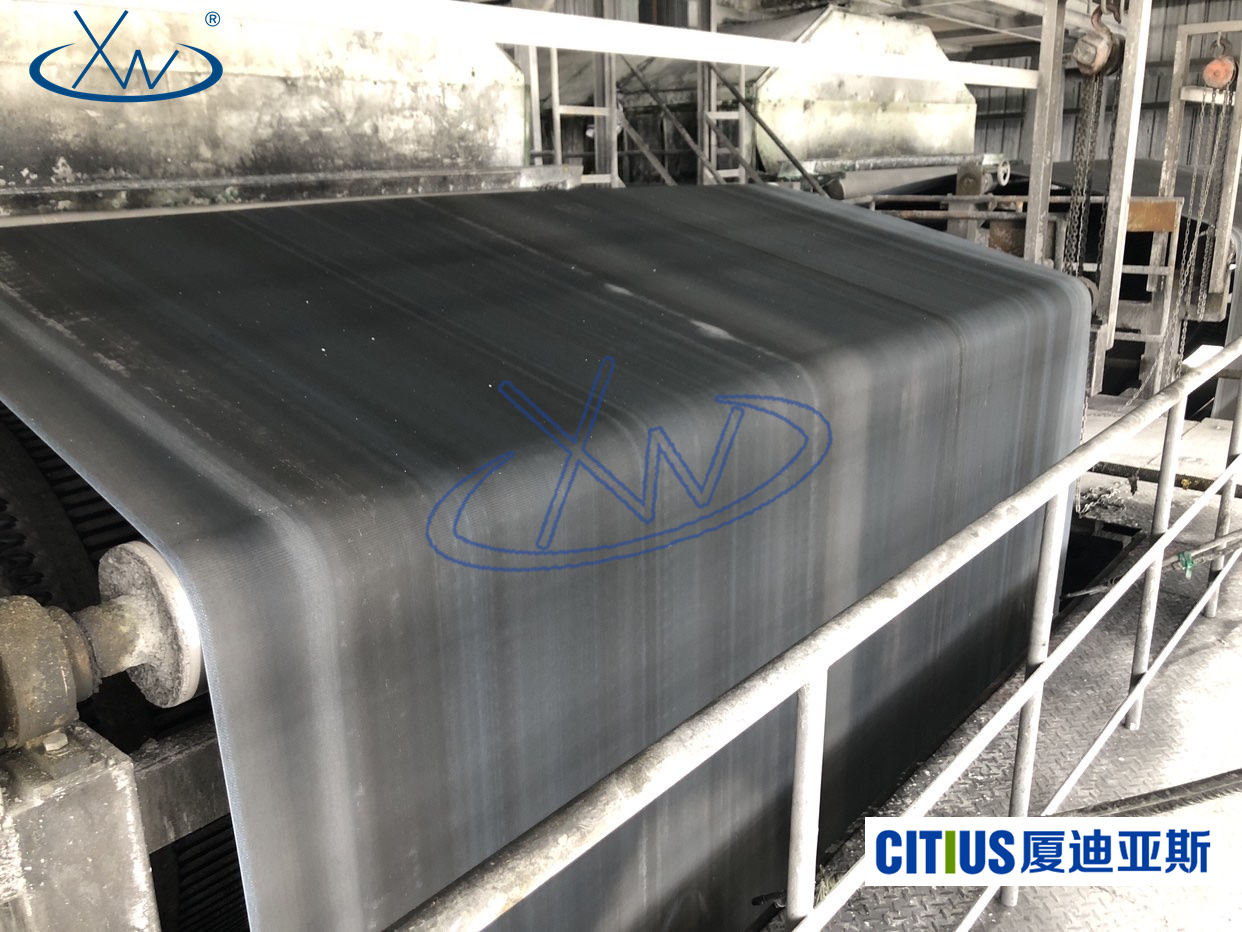

II. Application Advantages of Horizontal Vacuum Belt Filters

In response to the demand for wet-process phosphoric acid production, Horizontal Vacuum Belt Filter Becoming the mainstream choice. Its core advantages include:

- Large Processing Capacity and Continuity : Suitable for large-scale production in phosphate plants, enabling continuous feeding and continuous slag removal.

- The filter cake has high washing efficiency. : Multi-stage spray washing can be performed on the belt structure, significantly reducing the loss of phosphoric acid entrapped in the gypsum.

- Filtering accuracy is controllable By selecting the appropriate filter cloth specifications, it is possible to control both clarity and the moisture content of the filter cake.

- Highly automated : When paired with the vacuum system and automatic unloading device, it can reduce manual operations and enhance production stability.

In this system, Filter cloth is the core medium that determines separation quality. The selection of filter cloth directly affects the dewatering performance of the filter cake, washing efficiency, operational cycle, and maintenance costs.

3. Xadias CITIUS The technological advantages of industrial filter cloths

As A leading brand in the research and manufacturing of technical fabrics for filtration materials (mesh belts) , Xadias CITIUS In the research and development and manufacturing of filter cloths for horizontal vacuum belt filters, it boasts multiple advantages:

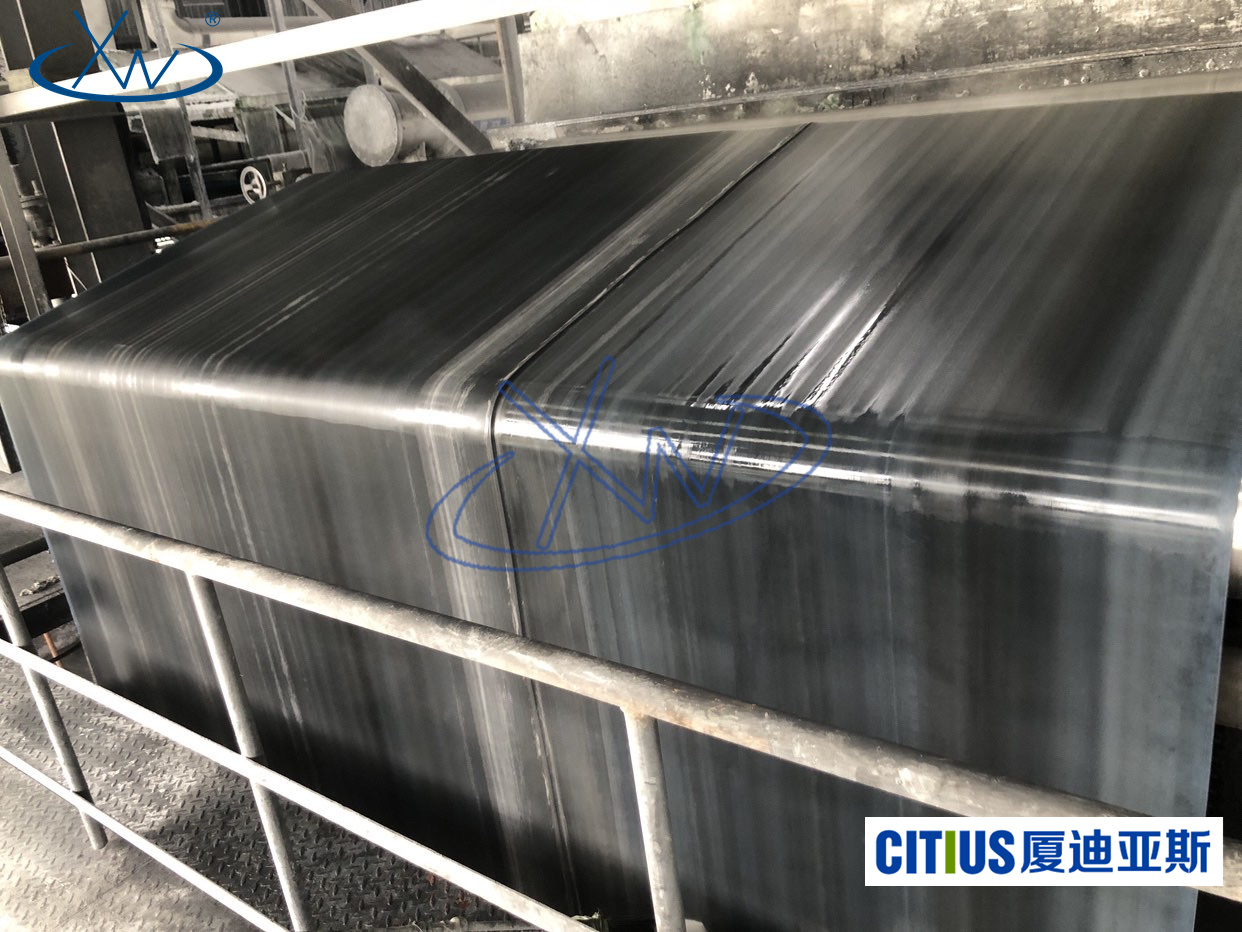

- Customized design

Regarding the particle size distribution and acidic characteristics of solid materials in wet-process phosphoric acid slurry, Xadias CITIUS We can provide filter cloth solutions with varying pore size distributions and weaving structures, ensuring both filtration accuracy as well as high air permeability and flow rate. - Strong corrosion resistance

The filter cloth is made from specially modified fiber materials, which can withstand the strong acids and impurities present in phosphoric acid systems, thereby extending its service life. - High Strength and Stability

The weaving process employs high-strength fibers and an optimized structural design, ensuring that the filter cloth remains resistant to deformation and breakage even under high tension and continuous operation. - Excellent filter cake release properties

Xadiaas CITIUS The filter cloth surface treatment process ensures that the gypsum filter cake easily detaches, minimizes residue, and enhances the filtration machine's operational efficiency. - Convenient Regeneration and Cleaning

The filter cloth boasts excellent anti-clogging performance, high cleaning recovery rates, and helps avoid downtime losses caused by frequent replacements.

IV. Application Cases and Industry Value

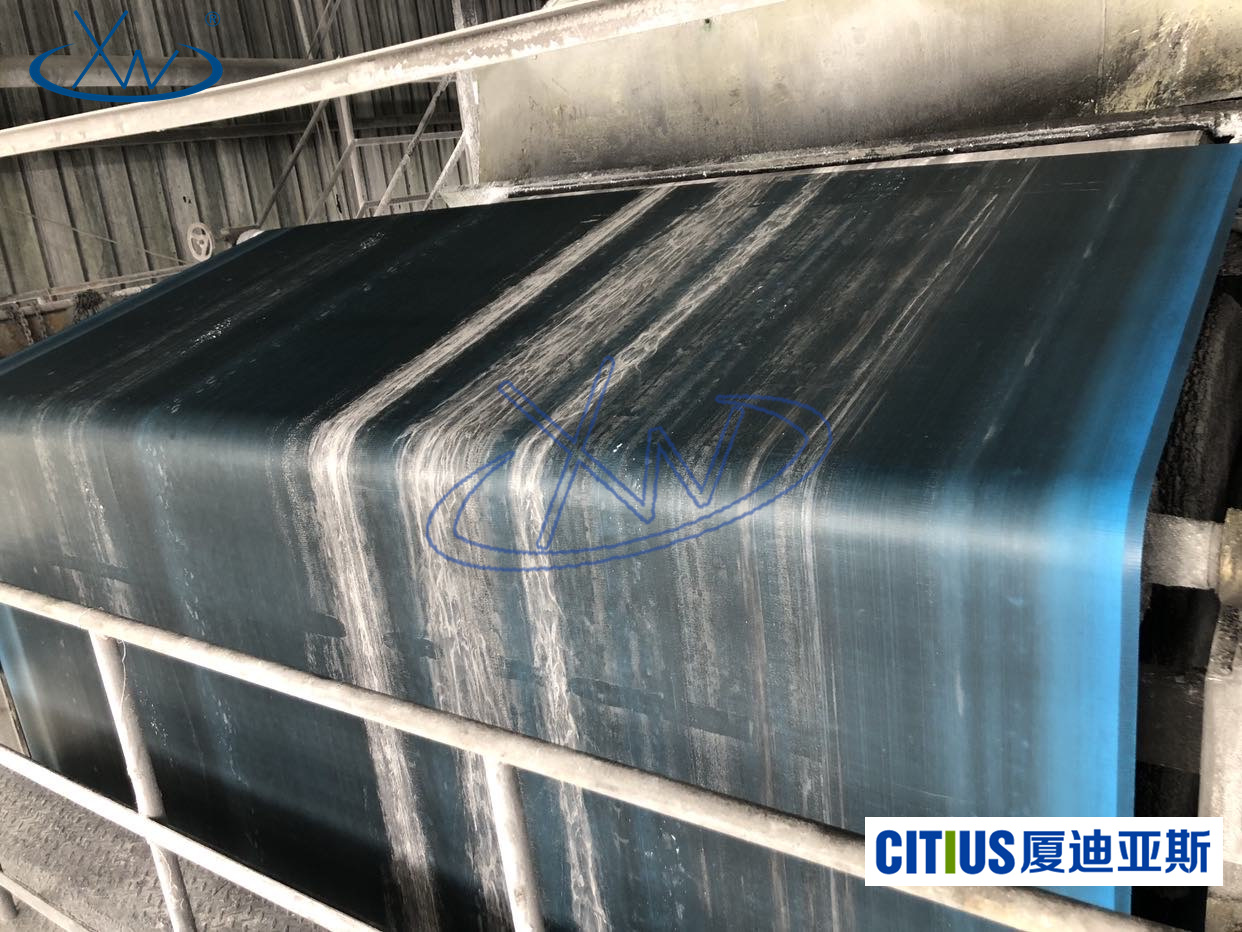

On the wet-process phosphoric acid production lines of several phosphate chemical enterprises, Xadias CITIUS The industrial filter cloth has been widely applied, demonstrating the following effects:

- Improve phosphoric acid purity : Solid-liquid separation is more thorough, significantly reducing the concentration of suspended solids in the filtrate, thereby creating favorable conditions for subsequent evaporation, concentration, and purification processes.

- Reduce the acid content in gypsum :The filter cake washing effect is remarkable, reducing phosphate entrainment and improving recovery rates.

- Extend the filter cloth's service life Compared to traditional filter cloths, Xadias CITIUS Enhanced product lifespan under strong acid conditions 30% That's all.

- Reduce operating costs : The filter cloth exhibits excellent cleaning performance, reducing replacement frequency and lowering overall operation and maintenance costs.

This not only helps businesses improve Production Stability and Economic Efficiency , and also helps the industry achieve Green, Clean Production Provided support.

V. Future Trends and Xadias CITIUS Continuous innovation

As the phosphate chemical industry moves toward High-efficiency, energy-saving, and eco-friendly The direction of development will lead to continuously increasing demands for solid-liquid separation equipment and filtration media. Future directions include:

- Higher-precision separation : Meeting the demand for electronic-grade phosphoric acid and new-materials-grade phosphoric acid.

- Intelligent Operation Monitoring : By integrating IoT technology, we can achieve real-time monitoring of filter cloth operating conditions and predict its lifespan.

- Environmental Protection and Sustainability : Developing recyclable and biodegradable filtration materials to align with the low-carbon production trend.

Xadiaas CITIUS We will continue to deepen our expertise in the industrial filter cloth sector, leveraging our independent R&D capabilities and fostering close collaboration with customers to consistently introduce innovative filter cloth products, thereby delivering superior solid-liquid separation solutions tailored specifically for the phosphate chemical industry.

Conclusion

In wet-process phosphoric acid production, Solid-liquid separation is not just a process—it is a critical step that determines both production efficiency and product quality. The combination of horizontal vacuum belt filters with high-performance filter cloths provides an ideal solution pathway for the industry. Xadias CITIUS Industrial filter cloth, thanks to its Corrosion-resistant, high-efficiency, long-lasting, customizable Its advantages are increasingly becoming the first choice for more and more phosphate chemical enterprises.

Looking toward the future, Xadias CITIUS It will continue to spearhead technological advancements in filtration materials, helping the phosphate chemical industry achieve more efficient, greener, and more sustainable development.

Solid-liquid separation – horizontal vacuum belt filter cloth – phosphate chemical treatment of phosphoric acid

Filter machine type: Horizontal vacuum belt filter

Application Industry: Phosphorus Chemicals

Handling Material Description: Phosphoric Acid

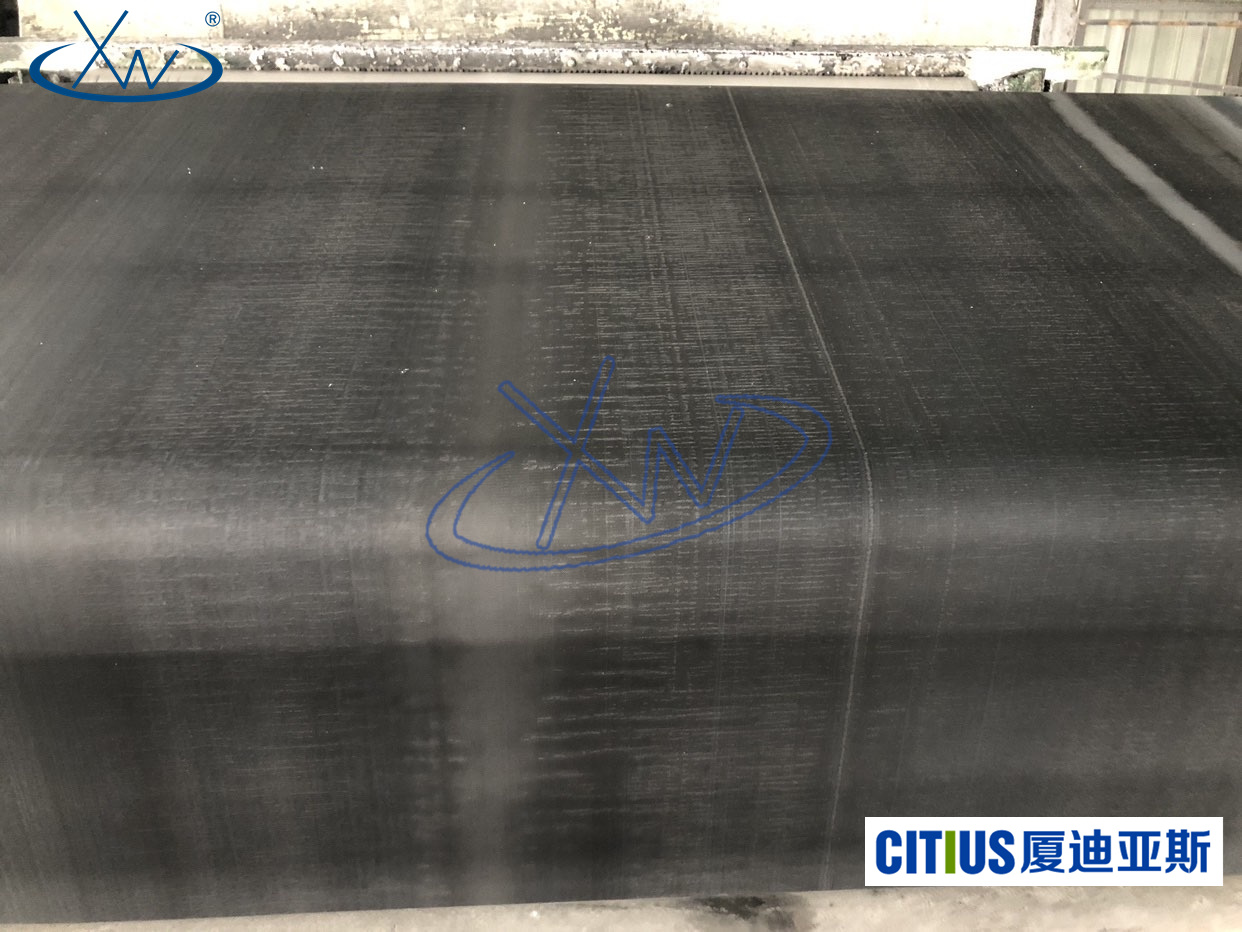

Filter cloth model: FC1224B