Machine-Woven Filter Cloth – Horizontal Vacuum Belt Filter – Chemical Calcium Carbide Slag

Share to

Detailed Description

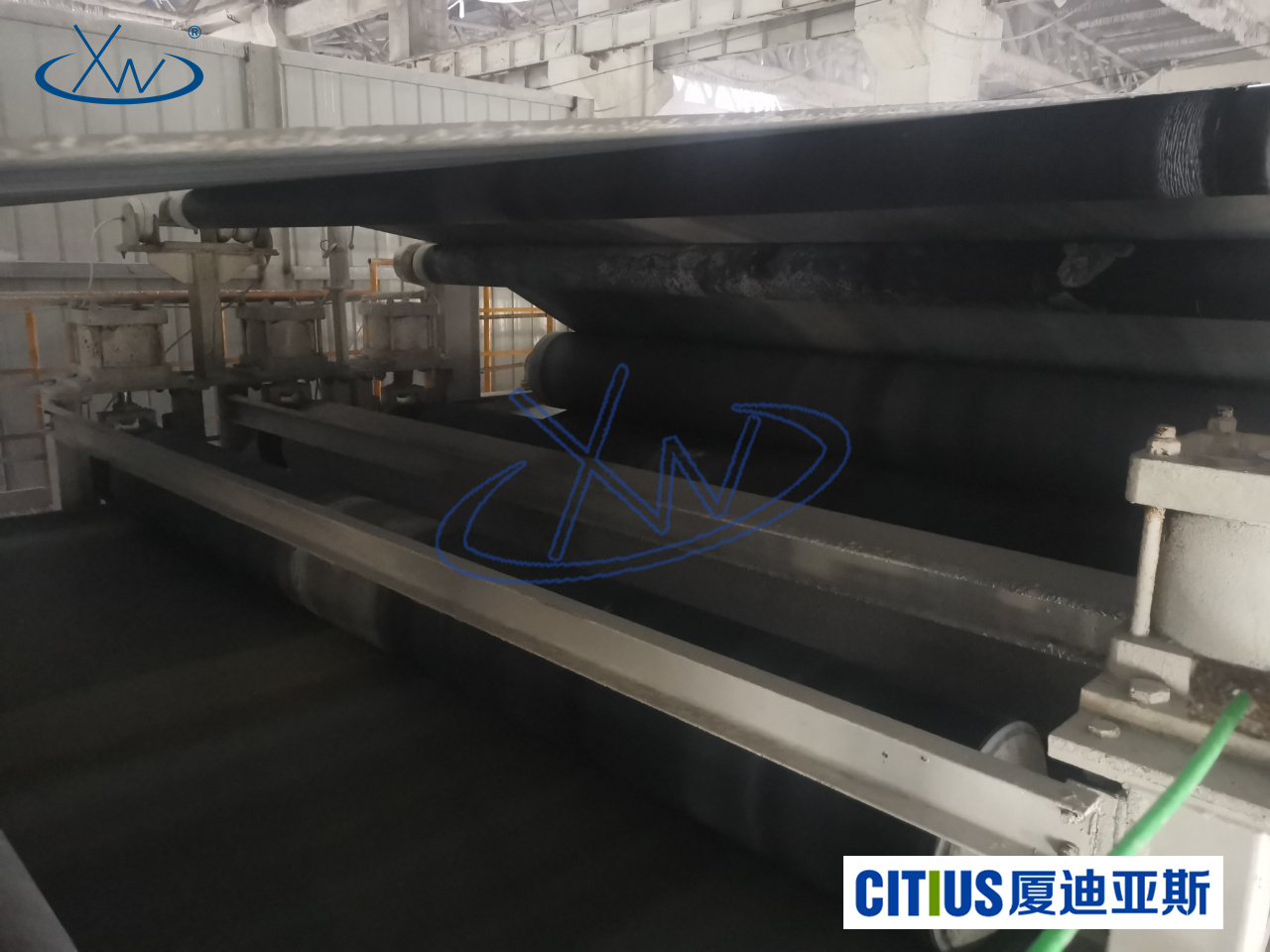

Analysis of the Application of Woven Filter Cloth in Horizontal Vacuum Belt Filters for Treating Chemical Calcium Carbide Residue

In the solid-liquid separation stage of the chemical industry, calcium carbide slag—also known as acetylene slag—is a typical type of solid waste material characterized by high moisture content, high alkalinity, and complex particle size distribution. As the industry increasingly emphasizes environmental protection, resource utilization, and economic efficiency, efficiently treating calcium carbide slag, reducing its moisture content, achieving compliant discharge standards, and simultaneously enhancing its value for subsequent comprehensive utilization have become central concerns for businesses. In this process, Horizontal vacuum belt filter equipped with high-performance woven filter cloth , has gradually become an important set of process equipment for chemical enterprises. Xadias CITIUS As a brand deeply rooted in industrial filter fabrics and filtration technology for three decades, we have accumulated extensive experience and innovative solutions in the field of calcium carbide slag treatment.

I. Industry Background and Challenges in Calcium Carbide Slag Treatment

Calcium carbide CaC ₂ ) In acetylene chemical industry and PVC Widely used across the industry, its production and application generate significant amounts of calcium carbide slag as a byproduct. The characteristics of calcium carbide slag include:

- Particle distribution is uneven. : It contains both fine powdery particles and coarse impurities, which can easily clog the filter cloth pores.

- High moisture content : The moisture content of untreated calcium carbide slag typically ranges from 70% Above all, if not dehydrated, it will not only be difficult to transport but also affect its subsequent use.

- Highly alkaline : Its ingredients often contain Ca(OH) ₂ , which has strong alkalinity and thus places extremely high demands on the chemical resistance of filter cloths.

- Large processing capacity : The calcium carbide slag produced daily by chemical plants is often continuous and generated on a large scale, requiring filtration equipment and filter cloths to be both stable and long-lasting.

Therefore, selecting the right solid-liquid separation equipment and filter cloth is crucial.

II. Advantages of the Horizontal Vacuum Belt Filter Machine

Among the many solid-liquid separation devices, the horizontal vacuum belt filter is widely used in calcium carbide slag treatment due to its continuous operation, large filtration area, and high degree of operational automation. Its key advantages include:

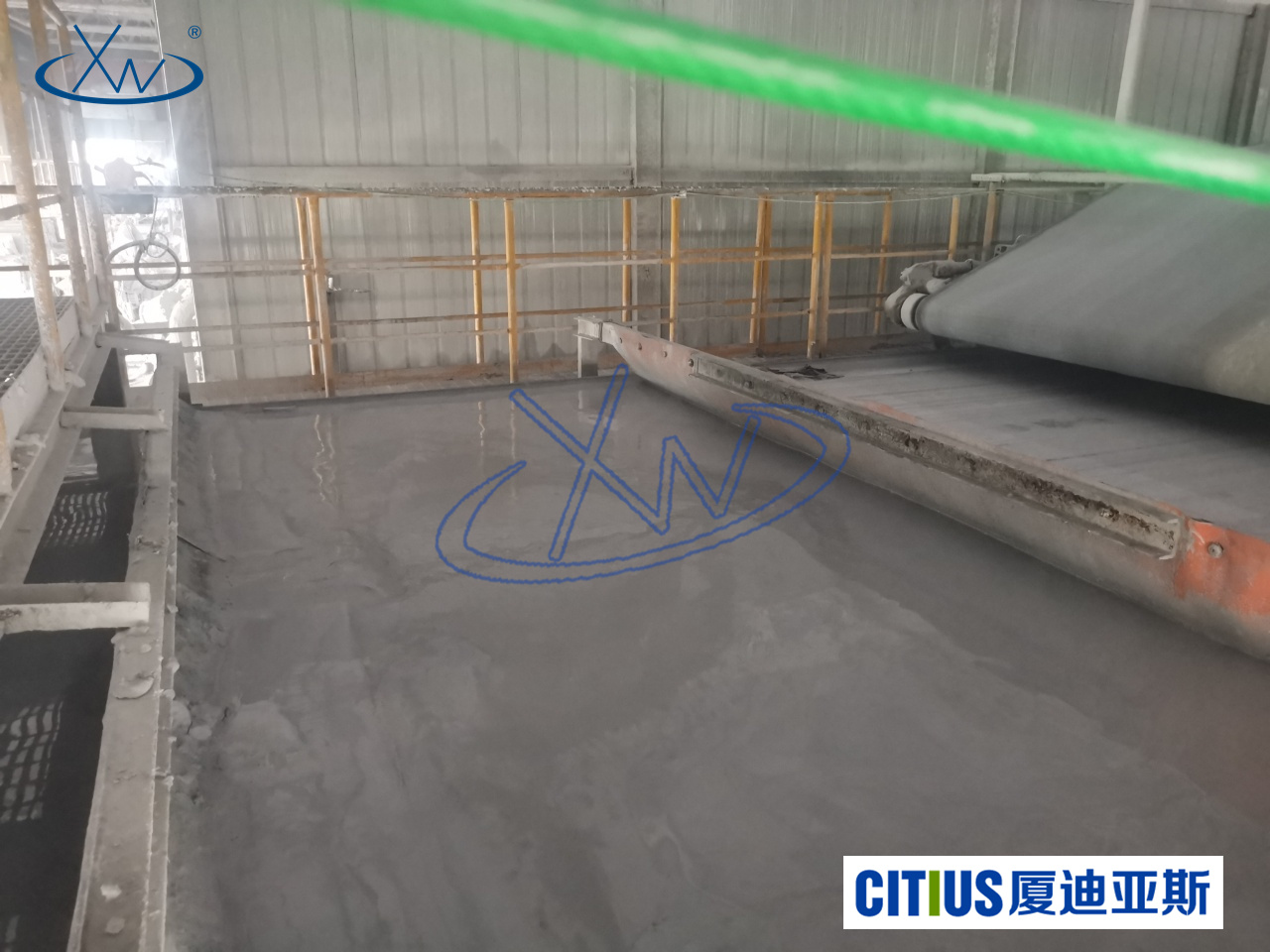

- Continuous Filtration and Washing : The material is evenly spread across the running filter belt, and solid-liquid separation is achieved under vacuum suction. At the same time, multi-stage countercurrent washing can be performed to remove impurities.

- High-efficiency dehydration Under vacuum negative pressure, the moisture content of calcium carbide slag can be significantly reduced, creating favorable conditions for subsequent storage or utilization.

- Sealed and environmentally friendly : The equipment is equipped with a sealing system that minimizes the leakage of alkaline waste liquid, enhancing environmental protection benefits.

- Highly adaptable It delivers excellent treatment performance for materials of varying particle sizes and concentrations.

However, the equipment's performance largely depends on the selection and quality of the filter cloth.

III. The Role of Woven Filter Cloth in Calcium Carbide Residue Filtration

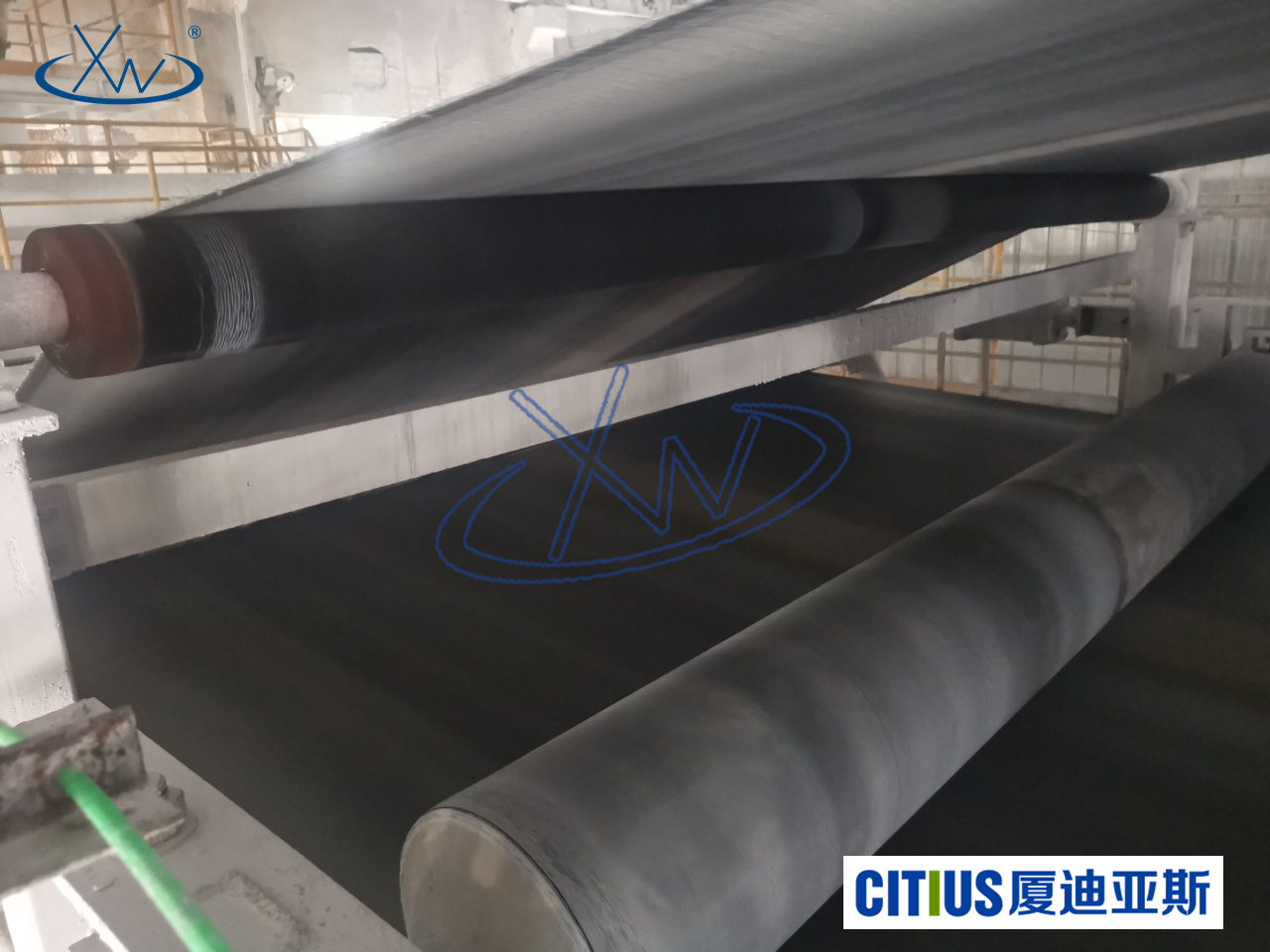

Machine-woven filter cloth, with its tight structure, uniform pores, and excellent resistance to abrasion and tension, is widely used in horizontal vacuum belt filters. For complex materials like calcium carbide slag, the advantages of machine-woven filter cloth are particularly pronounced:

- High strength and wear resistance

Calcium carbide slag particles have high hardness, and during operation, the filter cloth is continuously subjected to the combined effects of particle friction and vacuum suction. Xadias CITIUS Machine-woven filter cloth has been optimized in both warp and weft designs as well as yarn strength, enabling it to withstand prolonged tension and abrasion. - Excellent chemical resistance

Calcium carbide slag creates an alkaline environment, making ordinary filter cloths prone to chemical corrosion and significantly reducing their lifespan. Xadias CITIUS The machine-woven filter cloth has undergone both alkali-resistant treatment in material selection and post-processing techniques, ensuring stable performance even under highly alkaline conditions. - Reasonable pore size distribution

Addressing the issue of high fine-particle content and easy clogging in calcium carbide slag, Xadias CITIUS By controlling the pore size through weaving techniques, the filter cloth not only maintains high solid-liquid separation efficiency but also reduces the risk of clogging, thereby extending the cleaning cycle. - Good filter cake release properties

Calcium carbide slag tends to form a sticky filter cake during the filtration process. Xadias CITIUS The filter cloth surface has undergone special treatment, enhancing filter cake detachment efficiency, reducing downtime for cleaning, and improving equipment utilization.

4. Xadias CITIUS Solutions for industrial filter fabrics

Xadiaas CITIUS We offer a comprehensive suite of customized filter cloth solutions in the field of calcium carbide slag treatment, including:

- Textile Production Plan Optimization : Select the appropriate plain, twill, or satin weave structure based on the particle size distribution and concentration of the material, balancing filtration accuracy with air permeability.

- Diverse processing techniques : Offering specialized processes such as edge sealing, punching, and glue brushing to ensure tight compatibility between the filter cloth and equipment, enabling smoother operation.

- Cleaning and Regeneration Performance : Xadias CITIUS The filter cloth features excellent backwashing and online cleaning performance, boasts a long service life, and delivers low overall operating costs.

- Long-term technical support : The company's expert team will conduct an assessment of the customer's process site, offering recommendations such as material pre-treatment, filter cloth replacement cycles, and optimization of operating parameters, ensuring long-term stability in filtration performance.

V. Application Cases and Industry Value

At multiple PVC And in acetylene chemical enterprises, Xadias CITIUS Machine-woven filter cloth has been successfully applied to horizontal vacuum belt filters, enabling efficient dewatering and washing of calcium carbide slag. Practical results demonstrate:

- The moisture content of the calcium carbide slag filter cake is reduced to 40%-50% , facilitating subsequent transportation and stacking.

- Improved filtration efficiency 20% Above, the equipment's continuous operating time has been extended.

- The filter cloth replacement cycle has been extended, leading to a significant reduction in overall operation and maintenance costs.

- Complies with environmental protection requirements and reduces the risk of alkaline wastewater discharge.

Through these achievements, enterprises have not only addressed the challenging issue of solid waste management but also created opportunities for the comprehensive utilization of calcium carbide slag—such as its application in manufacturing building materials and as backfilling material—thus achieving a win-win situation that benefits both the economy and the environment.

VI. Future Trends

As “ Dual Carbon Goals ” With the development of the circular economy, the chemical industry will place greater emphasis on the resourceful utilization and eco-friendly treatment of calcium carbide slag. In the future, solid-liquid separation equipment and filter cloths will evolve in the following directions:

- Higher efficiency : The filter cloth will achieve a high dewatering rate with lower energy consumption.

- Intelligentization : Enhance operational automation through integrated online monitoring and automatic cleaning technologies.

- Materials Innovation : New corrosion- and wear-resistant fiber materials will be widely applied, enhancing the lifespan and filtration stability of filter cloths.

Xadiaas CITIUS We will continue to deeply invest in the R&D of industrial filter fabrics and process innovation, providing chemical companies with more competitive solid-liquid separation solutions.

Conclusion

In the process of treating calcium carbide slag using a horizontal vacuum belt filter, the machine-woven filter cloth serves not only as a physical filtration medium but also as a critical component ensuring the stable operation of the entire solid-liquid separation system. Xadias CITIUS Leveraging three decades of technological expertise and extensive industry experience, we can provide chemical companies with efficient, durable, and customized filter cloth products—helping customers achieve high-efficiency dewatering of calcium carbide slag, meet environmental standards, and enable resource recovery, thereby contributing to the industry's sustainable green development.

Machine-Woven Filter Cloth – Horizontal Vacuum Belt Filter – Chemical Calcium Carbide Slag

Filter machine type: Horizontal vacuum belt filter

Application Industry: Chemical Industry

Handling Material Description: Calcium Carbide Residue

Filter cloth model: T2054A-F4*8