Power Plant Desulfurization Gypsum Filter Cloth – Horizontal Vacuum Belt Filter – Filter Cloth Manufacturer

Share to

Detailed Description

Xadiaas CITIUS The Application of Industrial Filter Cloth in Desulfurization Gypsum Treatment at Power Plants

—— Practical Application of Solid-Liquid Separation Using a Horizontal Vacuum Belt Filter

In modern thermal power plants, desulfurization processes have become a core component of environmental protection and regulatory compliance. As countries implement increasingly stringent controls on sulfur dioxide emissions, limestone - Gypsum Wet Flue Gas Desulfurization FGD, Flue Gas Desulfurization ) has been widely adopted. This process effectively removes pollutants from flue gas, SO ₂ At the same time, it generates a large amount of byproducts with relatively high moisture content. —— Desulfurization gypsum—how to efficiently, economically, and reliably achieve solid-liquid separation of these byproducts directly impacts the environmental benefits and economic value of power plants.

In this segment, Horizontal vacuum belt filter equipped with high-performance industrial filter cloth Becoming a combination of key equipment and materials. Xadias CITIUS With over 30 years of industry experience, we have provided professional filter cloth solutions for desulfurization gypsum filtration in power plants, ensuring efficient and stable processes.

I. Process Challenges in Power Plant Desulfurization Gypsum Treatment

- Material properties are complex.

Desulfurization gypsum primarily consists of calcium sulfate dihydrate. CaSO ₄ · 2H ₂ O ) composed of various components, but often contains impurities such as limestone particles, fly ash, and incompletely reacted alkaline substances. The particle size distribution is broad, ranging from micrometers to hundreds of micrometers, leading to significant variations in filtration resistance and filter cake structure. - Moisture content requirements are stringent.

The typical goal for power plants when handling desulfurization gypsum is to reduce its moisture content, facilitating subsequent transportation, stockpiling, or comprehensive utilization—such as in building materials or gypsum board production. If the moisture content remains too high, it not only increases transportation costs but may also lead to secondary pollution. - Consistent and stable operating pressure

The power plant's desulfurization system typically operates in continuous mode, requiring equipment and filter cloths to withstand long-term, high-intensity work. If the filter cloth lacks sufficient strength, poor abrasion resistance, or inadequate anti-clogging performance, it can lead to frequent shutdowns and increased maintenance costs. - Dual Considerations of Environmental Protection and Economic Growth

On one hand, it is necessary to comply with environmental regulations; on the other hand, gypsum byproducts, as potential resources, become more marketable in the building materials sector the higher their quality. Moreover, the efficiency of the filtration process—and the resulting filter cake quality—directly determine the economic value of these byproducts.

II. Advantages of the Horizontal Vacuum Belt Filter Machine

The horizontal vacuum belt filter is renowned for its Continuous filtration, vacuum dewatering, and online washable filter cloth These characteristics are widely used in flue gas desulfurization gypsum treatment at power plants.

- Continuous filtration : Suitable for large-scale byproduct processing, ensuring production line stability.

- Vacuum dehydration Under vacuum suction, it can rapidly form a filter cake and effectively reduce the moisture content.

- Highly automated :The automatic filter cloth cleaning system reduces the frequency of manual maintenance.

- Highly adaptable : By adjusting operating parameters and filter cloth types, different compositions of desulfurization gypsum can be handled effectively.

In this process, the filter cloth serves to achieve solid-liquid separation. “ Core Medium ” The selection of filter cloth often determines the final efficiency of the equipment.

3. Xadias CITIUS The technological advantages of industrial filter cloths

As A leading brand in the research, development, and manufacturing of industrial filter fabrics , Xadias CITIUS A specialized series of filter cloths has been developed for the application of flue-gas desulfurization gypsum from power plants, featuring the following characteristics:

- Excellent filtration accuracy and water permeability

Xadiaas CITIUS The filter cloth has been optimized in terms of its weaving structure and pore size control, ensuring efficient retention of gypsum particles while maintaining appropriate permeability to prevent turbidity in the filtrate. - High strength and wear resistance

During long-term operation, the filter cloth must withstand vacuum suction, material scouring, and equipment friction. Xadias CITIUS The filter cloth is made from high-strength fibers and crafted using professional weaving techniques, extending its service life while reducing the costs associated with frequent replacements. - Good filter cake release properties

Desulfurization gypsum particles easily adhere to the surface of the filter cloth. Xadias CITIUS Improvements were made in the surface treatment and weaving design of the filter cloth, making it easier for the filter cake to detach and preventing secondary clogging. - Adapting to Continuous Cleaning

The power plant has filter cloths. “ Can be rinsed online ” The rigid requirements. Xadiaas CITIUS The filter cloth excels in wash resistance and structural stability, enabling it to maintain filtration performance over the long term. - Customized Solutions

Targeting different power plants and varying byproduct compositions, Xadias CITIUS We can offer personalized designs such as filter cloth material, thickness, weaving style, and edge reinforcement, ensuring the best possible fit.

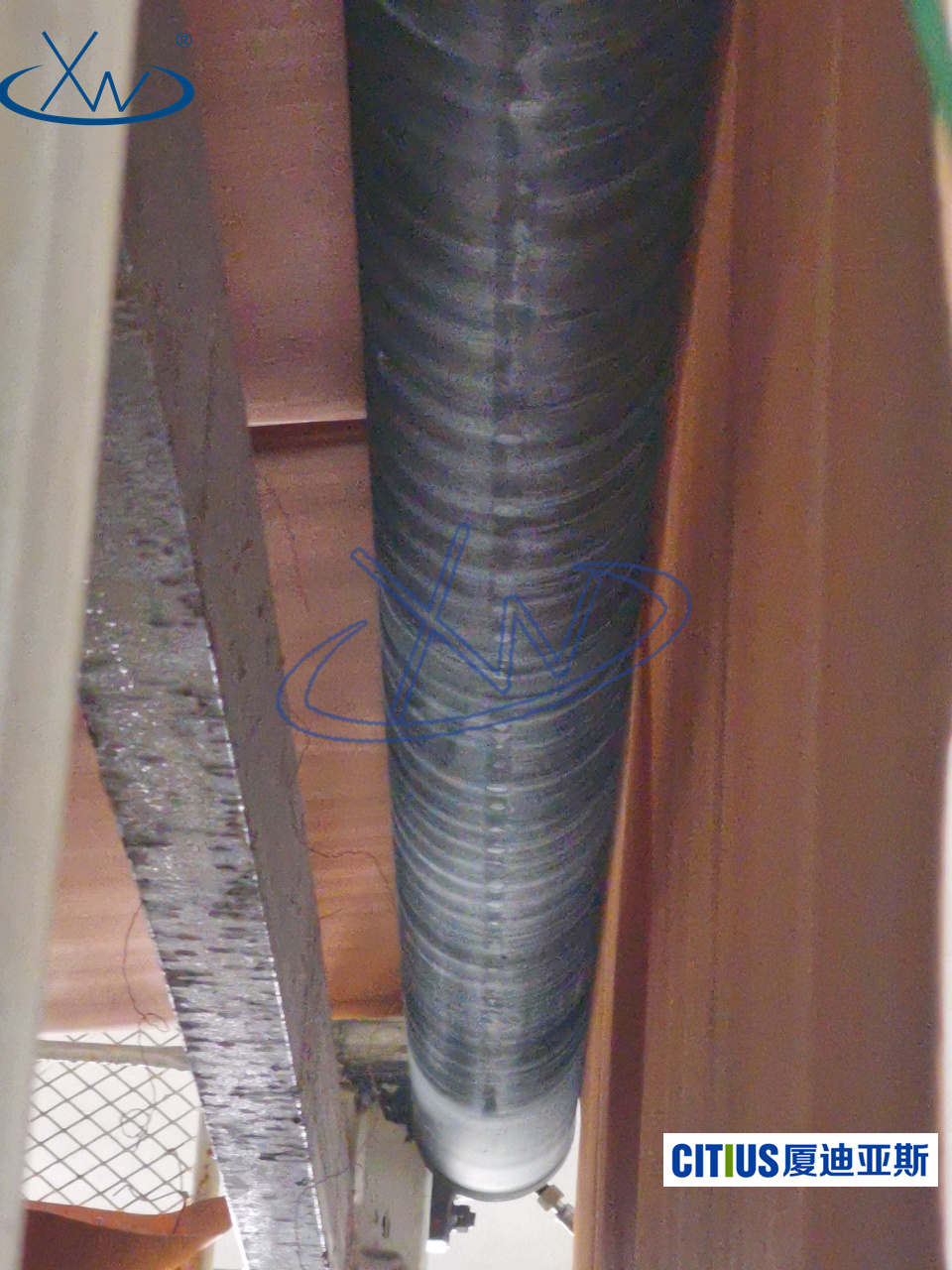

IV. Case Study on Application Effects

At a large coal-fired power plant, a horizontal vacuum belt filter is paired with Xadias. CITIUS Filter cloth used for desulfurization gypsum treatment:

- Operating Status : Continuous operation exceeding 6 For months, the filter cloth has maintained excellent strength and water permeability.

- Filtration Efficiency :The clarity of the filtrate was significantly improved, and the moisture content of the filter cake was stably maintained at 10–12% Between.

- Economic and Environmental Benefits : The filter cake can be directly used as a raw material for gypsum boards, reducing waste accumulation; the filter cloth lifespan is also extended. 30% Above, this saves nearly one million yuan in replacement costs each year.

This case demonstrates that Xadias CITIUS The filter cloth not only addresses the pain points in equipment operation but also helps the power plant strike a balance between environmental compliance and resource utilization.

V. Industry Trends and Outlook

As “ Dual-Carbon Strategy ” While the overall scale of the thermal power industry is gradually shrinking, the desulfurization systems in existing units still need to operate reliably and stably over the long term. Looking ahead, the comprehensive utilization rate of desulfurization gypsum by-products will continue to increase, placing even higher demands on solid-liquid separation technologies.

- High-efficiency and energy-saving : The filter cloth will play a greater role in reducing energy consumption and improving filtration efficiency.

- Green and Eco-Friendly : Recyclable, long-lasting filter cloth designs will become the focus of research and development.

- Digital Operations and Maintenance Intelligent monitoring combined with predictive maintenance to optimize filter cloth performance is set to become the new trend in power plant operations and maintenance.

Against this backdrop, Xadias CITIUS We will continue leveraging technological innovation to support the upgrade of power plant solid-liquid separation systems, providing the industry with reliable and environmentally friendly solutions.

Conclusion

Power plant desulfurization gypsum treatment is not only an environmental protection project but also a crucial step in resource utilization. In horizontal vacuum belt filters, the filter cloth—acting as the core component—directly determines the success or failure of solid-liquid separation. Xadias CITIUS Leveraging its expertise in the R&D and manufacturing of industrial filter fabrics, the company provides power plants with efficient, reliable, and cost-effective solutions, helping them achieve green operations and sustainable development.

It is foreseeable that, as environmental protection requirements and the level of resource utilization continue to rise, Xadias CITIUS Industrial filter fabrics will continue to play a vital role in the flue-gas desulfurization gypsum sector of power plants, contributing to clean energy and the circular economy.

Solid-Liquid Separation – Horizontal Vacuum Belt Filter Cloth – Power Plant Desulfurization Gypsum

Filter machine type: Horizontal vacuum belt filter

Application Industry: Power Plants

Handling Material Description: Gypsum

Filter cloth model: 1029