Filter press cloth nylon monofilament filter cloth - plate and frame filter press - paper and pulp dehydration

Share to

Detailed Description

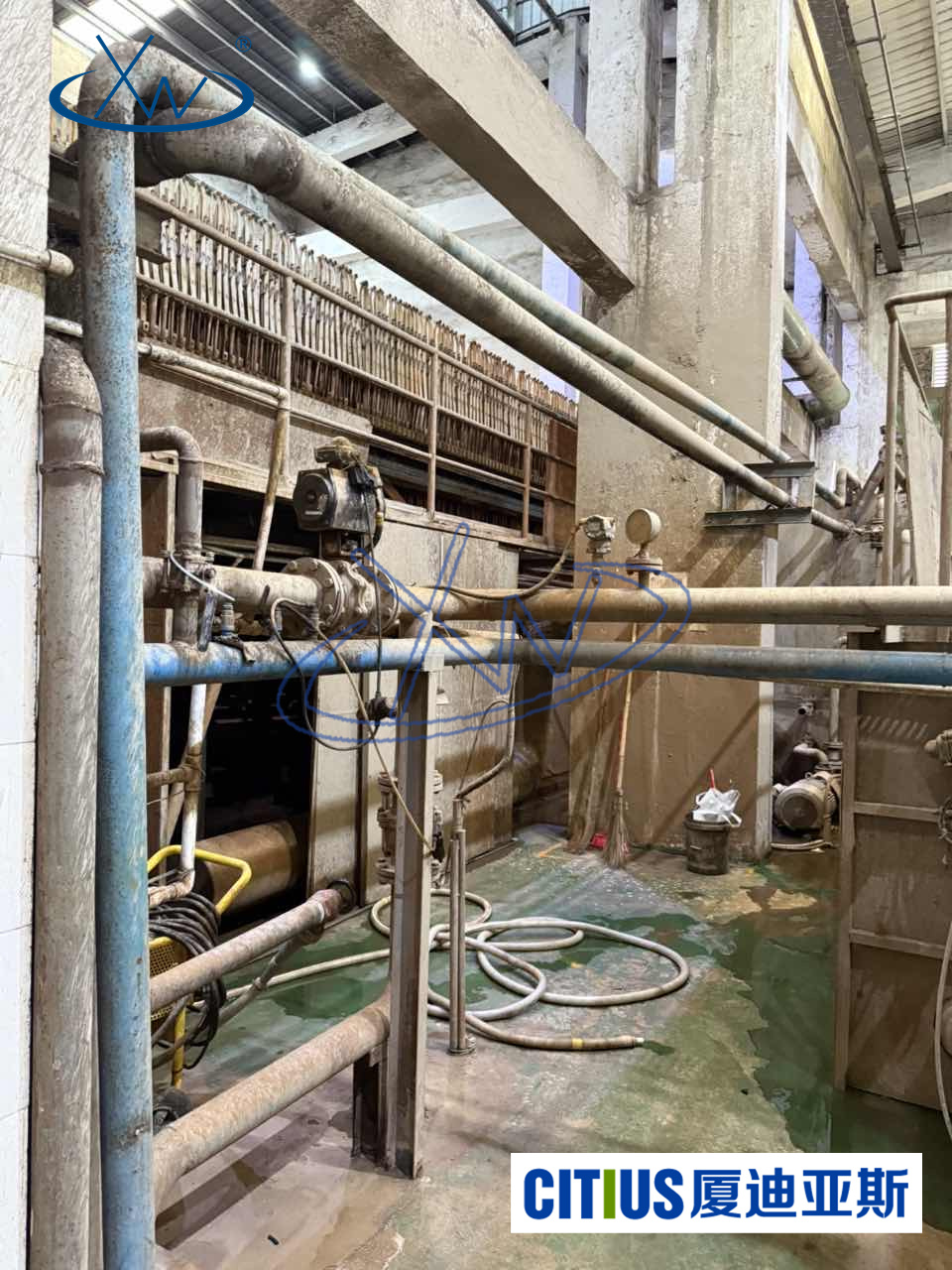

- Filter press cloth nylon monofilament filter cloth - plate and frame filter press - paper and pulp dewatering

Filter press type: plate and frame filter press

Application industry: paper industry

Material description: pulp wastewater

Filter cloth model used: nylon monofilament

The application value of industrial filter cloth in paper and pulp dewatering —— Focusing on the synergistic advantages of nylon monofilament filter cloth and plate and frame filter press

The application value of industrial filter cloth in paper and pulp dewatering —— Focusing on the synergistic advantages of nylon monofilament filter cloth and plate and frame filter press

In the papermaking industry, pulp dewatering is one of the most critical processes. The quality of dewatering directly determines the pulp concentration, production efficiency, and the final physical properties of the paper. With the continuous improvement of product quality, energy consumption control, and environmental protection requirements in the industry, traditional dewatering methods face new challenges. How to ensure production capacity while achieving higher water filtration efficiency and lower energy consumption has become a common concern for paper enterprises.

Against this background, the combination of nylon monofilament filter cloth and plate and frame filter press has gradually become the ideal solution in the pulp dewatering process of the paper industry. It not only improves the solid-liquid separation effect but also shows significant advantages in filter cloth lifespan, cleanliness, and operating costs.

1. The role and value of industrial filter cloth

Industrial filter cloth, as the core material for solid-liquid separation, directly reflects the performance of filtration equipment. In the pulp dewatering process, the filter cloth undertakes " the dual tasks of intercepting fiber particles and allowing water to pass smoothly ” ". An ideal filter cloth must not only have sufficient mechanical strength to withstand the high-pressure squeezing of the plate and frame press but also maintain a balance between filtration speed and interception efficiency.

Traditional fiber filter cloths in pulp filtration are often prone to clogging and difficult to clean, leading to shortened operation cycles and increased energy consumption. With the diversification of papermaking raw materials (wood pulp, grass pulp, recycled pulp, etc.) and the widespread use of environmentally friendly additives, higher adaptability requirements are placed on filter cloths. At this point, the advantages of nylon monofilament filter cloth become apparent.

2. Unique advantages of nylon monofilament filter cloth

- Excellent filtration efficiency

The nylon monofilament structure is uniform with reasonable pore distribution, enabling rapid discharge of filtrate and improving pulp dewatering speed. Under the high-intensity squeezing of the plate and frame press, the filter cloth can still maintain stable permeability, ensuring production rhythm is not affected. - Outstanding wear resistance and mechanical strength

In the working environment of the plate and frame filter press, the filter cloth must endure repeated pressing and peeling. The high strength and wear resistance of nylon monofilament significantly extend the filter cloth's service life, reducing replacement frequency. - Resistant to clogging and easy to clean

Compared to multi-fiber filter cloths, the monofilament surface is smooth and less likely to trap fibers and impurities. This characteristic reduces the risk of filter cloth clogging and maintains good permeability even with high-concentration pulp or pulp containing more impurities. - Good chemical stability

Papermaking processes often involve acid and alkali bleaching and chemical additives. Nylon monofilament filter cloth has strong chemical corrosion resistance, enabling stable operation in complex chemical environments.

3. The value of plate and frame filter press in pulp dewatering

The plate and frame filter press is widely used in pulp concentration and dewatering in paper mills due to its simple structure, high filtration precision, and strong adaptability. Its core principle is to intercept fiber solids in the pulp through filter cloth and discharge liquid under pressure, achieving solid-liquid separation.

Compared with vacuum dewatering or gravity concentration methods, the advantages of the plate and frame filter press are:

- Thorough dewatering It can reduce the pulp moisture content to a low level, decreasing energy consumption in subsequent drying.

- Strong adaptability It can handle pulp from different sources and concentrations, including recycled pulp.

- High filtration precision Ensures clear filtrate, which is beneficial for pulp recycling.

When the plate and frame filter press is used with nylon monofilament filter cloth, performance improvement is even more significant. The permeability and anti-clogging properties of nylon filter cloth allow the equipment to operate stably under high pressure, reduce downtime for cleaning, and improve overall production efficiency.

4. Industry trends in paper pulp dewatering

With the advancement of " the dual carbon goals ” and the accelerated green transformation of the global papermaking industry, the pulp dewatering process is showing the following trends:

- Energy saving and consumption reduction

The more thorough the dewatering, the lower the energy consumption in the subsequent drying stage. Using efficient filter cloth and advanced equipment has become an important means for enterprises to reduce energy costs. - Recycling and environmental protection requirements

The clarity of pulp filtrate directly affects whether it can be recycled. Efficient filtration materials can improve water recycling rates and reduce wastewater discharge pressure. - Long service life and low maintenance

Frequent filter cloth replacement not only increases costs but also affects production rhythm. Therefore, longer-lasting and easy-to-clean nylon monofilament filter cloth meets the industry's demand for high stability. - Intelligent and customized solutions

Future pulp dewatering systems may increasingly integrate online monitoring and intelligent control. Filter cloth selection will also move towards " customization ” to provide differentiated solutions based on pulp characteristics and equipment parameters.

5. Practical significance of nylon monofilament filter cloth + and plate and frame filter press

In practical applications, the combination of nylon monofilament filter cloth and plate and frame filter press brings multiple benefits to paper enterprises:

- Higher dewatering efficiency Shortened production cycles and increased output.

- Reduced energy consumption Decreased energy use in the drying process, aligning with green production concepts.

- Stable operational performance Reduced risk of clogging and downtime, ensuring long-term stable operation of equipment.

- Economic advantages Long filter cloth lifespan, low maintenance costs, and more competitive overall operating costs.

For paper enterprises, this is not only a process improvement but also an inevitable choice to achieve green production and cost control.

Conclusion

Pulp dewatering, as a key link in the papermaking process chain, directly affects the overall efficiency of paper production through its efficiency and quality. Nylon monofilament filter cloth, with its wear resistance, ease of cleaning, and anti-clogging properties, forms a powerful combination with plate and frame filter presses, providing an efficient, economical, and sustainable solution for pulp dewatering in the paper industry.

Against the backdrop of the industry's accelerated green transformation and pursuit of high-quality paper products, the promotion and application of this combination will bring longer-term competitive advantages to paper enterprises.