Industrial Filter Cloth - Vertical Filter Press Cloth - Pesticide Glyphosate

Share to

Detailed Description

Vertical Filter Cloth - Vertical Filter Press - Pesticide Glyphosate

Filter Machine Type: Vertical Filter Press

Application Industry: Pesticide

Material Description: Glyphosate

Filter Cloth Model: 2012

Application of Industrial Filter Cloth and Vertical Filter Press in Pesticide Glyphosate Production

In modern pesticide production, glyphosate, as an important broad-spectrum herbicide, involves various chemical reactions and solid-liquid separation processes. Efficient solid-liquid separation not only directly affects product quality but also impacts production costs and environmental protection levels. The vertical filter press combined with high-performance industrial filter cloth has become an indispensable key equipment combination in glyphosate production.

1. Challenges of Solid-Liquid Separation in Glyphosate Production

During glyphosate production, the reaction system usually contains various solvents, inorganic salts, and unreacted raw materials, producing a slurry solid. Traditional separation methods such as settling and centrifugation have the following limitations:

- Low Separation Efficiency : Difficult to completely retain fine particles, leading to reduced yield;

- Long Operation Cycle : Multiple filtrations or settling are time-consuming, affecting production rhythm;

- High Moisture Content in Filter Cake : Increases subsequent drying load, affecting energy consumption and equipment lifespan.

2. Advantages of Vertical Filter Press in Glyphosate Production

The vertical filter press is a highly efficient solid-liquid separation device characterized by a large filtration area, compact structure, and easy operation. Compared with traditional horizontal plate and frame filter presses, the vertical filter press has the following advantages:

- High Separation Efficiency : Through multi-layer filter plates and uniform pressure distribution, solid particles in the slurry quickly aggregate, significantly reducing filtrate turbidity;

- Energy Saving and Environmental Protection : Reduces secondary filtration and reflux, improves raw material utilization, and lowers wastewater treatment load;

- High Degree of Automation : Modern vertical filter presses can achieve automatic feeding, pressing, and discharging, reducing manual operation risks;

- Strong Adaptability : Can handle slurries with different viscosities, particle sizes, and solid contents, meeting the diversified process requirements of glyphosate production.

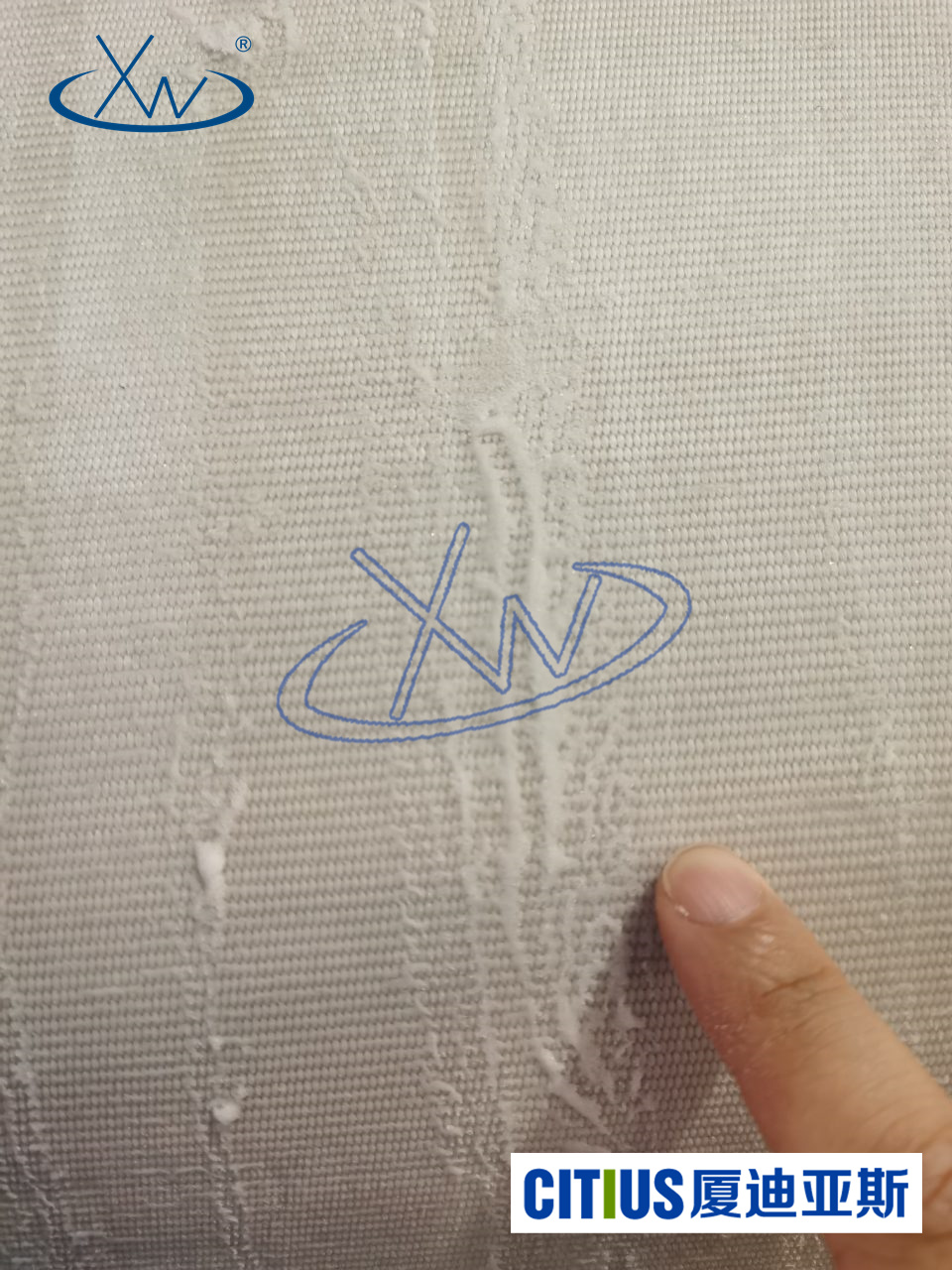

3. Key Role of Industrial Filter Cloth

As the core component of the vertical filter press, the performance of the filter cloth directly determines the efficiency of solid-liquid separation and the quality of the filter cake. For glyphosate production, industrial filter cloth needs to have the following characteristics:

- High Chemical Resistance : Able to withstand acidic, alkaline, and organic solvent environments in glyphosate production;

- Good Permeability : Ensures rapid filtrate flow while retaining fine solids;

- Wear Resistance and Durability : Long-term use without easy damage, reducing maintenance costs;

- Easy to Clean : Filter cloth is easy to clean and replace, ensuring production continuity.

Modern industrial filter cloth materials can be customized according to glyphosate production conditions, such as polyester, polypropylene, and special woven structures, meeting filtration needs for different particle sizes and slurry characteristics.

4. Application Cases and Effects

In practical applications, a glyphosate production enterprise introduced a vertical filter press equipped with high-performance industrial filter cloth and achieved the following results:

- Filtrate clarity improved, solid recovery rate reached 95% and above;

- Filter cake moisture content reduced by about 3-5% , reducing subsequent drying energy consumption;

- Production cycle shortened 20% , and production efficiency significantly improved;

- Equipment operation is stable, and maintenance costs reduced by about 15%。

5. Conclusion

With the pesticide industry's increasing demands for production efficiency, environmental standards, and product quality, the combination of vertical filter press and high-performance industrial filter cloth will become the preferred solution for solid-liquid separation in glyphosate and other pesticide productions. By optimizing filter cloth materials, filter plate structures, and automation control, enterprises can not only increase capacity but also gain significant advantages in energy saving and environmental protection.