Gypsum desulfurization and dehydration filter cloth recommendation | Horizontal vacuum belt filter matching scheme

Share to

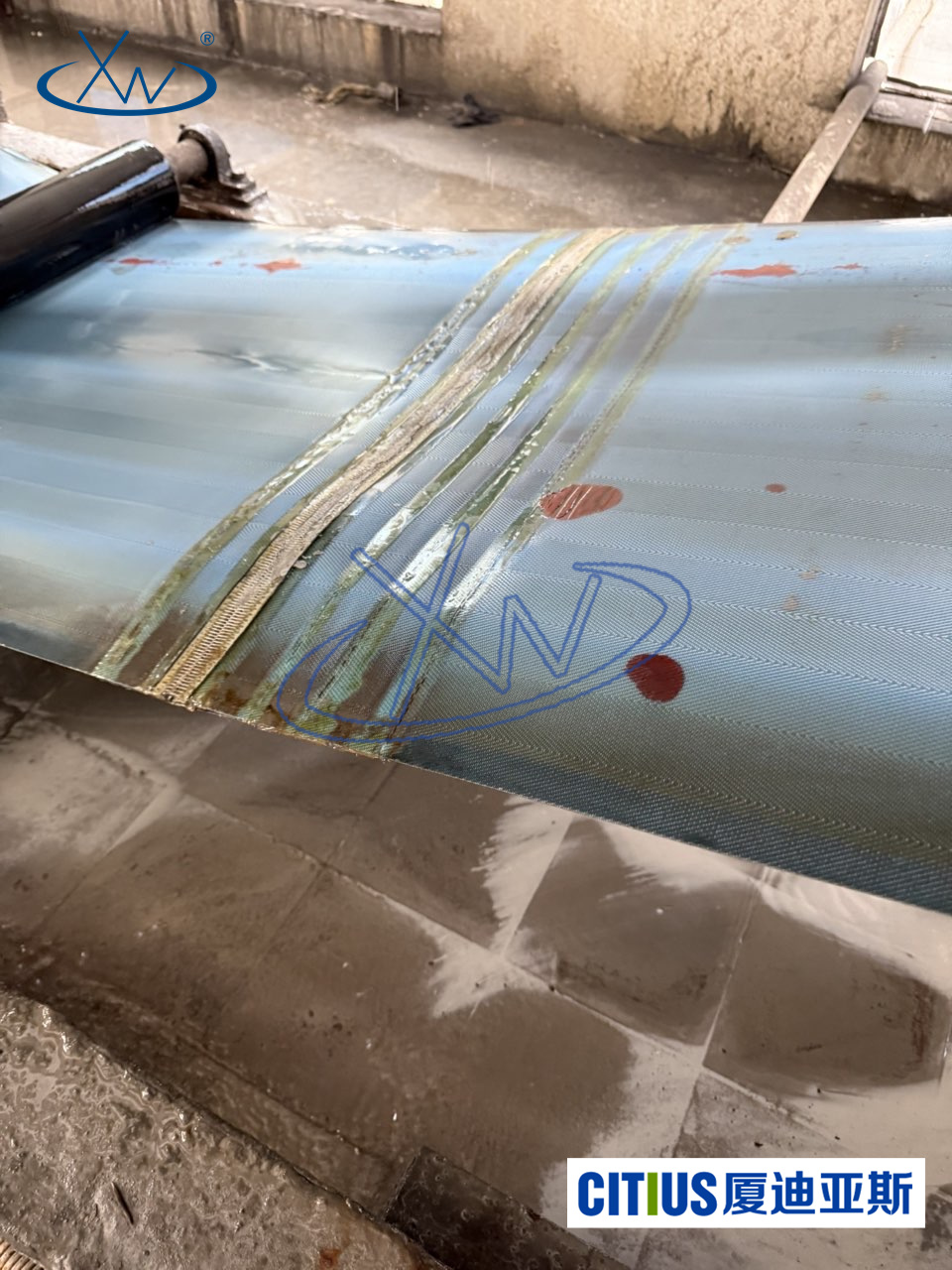

Detailed Description

Key aspects of gypsum desulfurization and dehydration:

Path to improve collaborative efficiency of horizontal vacuum belt filters and industrial filter cloths

In the " Dual Carbon ” Under the continuous advancement of policies, industries such as thermal power, metallurgy, and chemical engineering are facing increasingly stringent emission control standards for flue gas. Limestone - Gypsum Wet Flue Gas Desulfurization (WFGD) Technology ( WFGD ) as a mature and mainstream desulfurization process, is being widely deployed in major enterprises. In this process, the desulfurization byproduct gypsum's efficient dehydration and resource utilization become the focus of attention. This article will focus on industrial filter cloths and horizontal vacuum belt filters integrated application in gypsum desulfurization and dehydration, analyzing their impact on filtration efficiency, operational stability, and overall system benefits.

01 Desulfurization Byproduct Gypsum: Resource or Burden?

The limestone wet desulfurization process absorbs flue gas SO ₂ , ultimately producing a wet gypsum slurry. The solid content of this gypsum is usually between 15%~20% , with fine particle size and mixed with some unreacted lime and impurities. Improper handling can easily lead to:

- High filter cake moisture content, increased transportation and stacking costs

- High impurities in filtrate, creating a burden for reuse

- Filter cloth easily clogs, unstable operation, affecting system continuity

Desulfurized gypsum dehydration is not only about its subsequent utilization value (e.g., cement retarder, gypsum board for construction, etc.), but also determines the overall operating efficiency and environmental performance indicators of the desulfurization system.

02 Horizontal Vacuum Belt Filter: Adaptability and Advantages

Compared to traditional methods such as centrifugal dewatering and plate-and-frame filter pressing, Horizontal Vacuum Belt Filter ( HVBF ) has become the main equipment for gypsum desulfurization and dehydration due to its continuous operation, stable filter cake, and excellent washing effect. Its core advantages are reflected in the following aspects:

▶ Continuous Operation and Automatic Control

The horizontal vacuum filter adopts a continuous belt operation mode, suitable for conditions with stable slurry and large processing capacity. Coupled with an online monitoring and automatic control system, it can dynamically adjust slurry feed volume, vacuum degree, and filter cake thickness, improving system responsiveness and energy saving levels.

▶ Stable Filter Cake Quality, Uniform Dehydration

The filter cloth completes solid-liquid separation in the vacuum zone. During operation, the filter cake undergoes gas-assisted dehydration and multi-stage washing, making the dry solid content more controllable, and the filter cake thickness more consistent, which facilitates subsequent stacking and transportation.

▶ Excellent Energy Saving and Environmental Performance

The vacuum filtration system consumes less energy than the pressure filtration system, and its sealed structure reduces slurry splashing and odor emissions, which is more in line with current green manufacturing concepts.

03 Process Role and System Coupling of Filter Cloth

Although the equipment has advantages in physical configuration, what truly determines the dewatering effect is the industrial filter cloth system that operates with it. In gypsum desulfurization and dehydration, the filter cloth not only serves as a filtration medium function, but also plays multiple coupled engineering roles:

① Filtrate Channel: Affects Dehydration Rate and Vacuum Efficiency

The structural characteristics of the filter cloth affect the filtrate's permeability per unit time, directly determining the filtration speed, filter cake thickness control, and the overall vacuum filtration efficiency.

② Filter Cake Support Layer: Determines Filter Cake Morphology and Release Properties

The flatness of the filter cloth surface, pore configuration, and surface treatment technology together affect the quality of filter cake formation. High-quality filter cloth can effectively prevent problems such as uneven filter cake distribution and severe adhesion, improving peeling efficiency and filter cloth regeneration performance.

③ Multi-field Coupled Action Medium: Affects System Stability and Operating Cycle

In extreme environments such as high temperature, high humidity, and high viscosity, the filter cloth needs to have sufficient chemical stability, mechanical strength, and anti-fatigue performance to ensure continuous operation over long periods.

Thus, it can be seen that industrial filter cloth is not only a filtration " channel ” , but also a " variable ”。

04 Typical Application Strategies: From Filter Cloth Structure Optimization to System Coordinated Adjustment

■ Zoned Filtration and Vacuum Curve Optimization

To meet the dewatering needs of different regions of desulfurized gypsum, different structural parameters of filter cloth can be configured, combined with a gradient vacuum curve, to achieve " multi-stage filtration ” . The front section enhances filtration speed to increase solid content, the middle section strengthens washing, and the rear section performs deep dewatering and drying, effectively improving the overall dewatering ratio.

■ Automatic Tensioning and Deviation Correction Control

To adapt to different filter cloth operating conditions and wear changes, HVBF The system is usually equipped with automatic tensioning and deviation correction devices. Precise tension control can slow down the fatigue aging of the filter cloth, extend its service life, and ensure the stability of the filter cloth under high-load operation.

■ Online Cleaning and Backwash Device

During online operation, the filter cloth is susceptible to blockage by fine gypsum particles, reducing its air permeability. Through online cleaning technologies such as high-pressure water jets and reverse spraying, continuous filter cloth " self-cleaning ” , reducing the frequency of downtime for cleaning and improving equipment utilization.

05 Project Practice: Value Embodiment of Integrated Dewatering Systems

In several large-scale power and steel industry FGD projects, the dewatering line using industrial filter cloth and HVBF system combination has shown significant results:

- Filter cake moisture content controlled at 30%~33%

- System annual average operating efficiency reached 98% or above

- Increased resource utilization rate of desulfurized gypsum 20%

More importantly, a good filtration system can significantly reduce downstream sludge treatment, storage, and transportation costs, lower operational carbon footprint, and achieve true " environmental protection and efficiency enhancement ”。

06 Conclusion: System Optimization, Promoting Green Transformation

As environmental standards become stricter and the comprehensive utilization of desulfurized gypsum deepens, filtration systems have evolved from " end-of-pipe treatment equipment ” gradually upgraded to front-end core link for resource utilization . Building efficient, stable, and low-energy dewatering systems using horizontal vacuum belt filters as a platform and industrial filter cloth as the key medium is becoming an industry consensus.

In the future, the value of filtration systems will not only be limited to " filtration itself ” , but will expand towards intelligent operation and maintenance, process chain coupling, data visualization, and other directions, providing stronger technical support for the green upgrade of desulfurization processes and resource closed-loop.

- Recommended Filter Cloth for Gypsum Desulfurization and Dewatering | Matching Solution for Horizontal Vacuum Belt Filters

Filter Type: Horizontal Vacuum Belt Filter

Application Industry: Gypsum Desulfurization

Material Description: Gypsum Desulfurization

Filter Cloth Model: 15T