Plate and frame filter press filter cloth application in brewery wort filtration

Share to

Detailed Description

From Malt to Wort: The Key Application of Industrial Filter Cloth in Brewery Plate and Frame Filter Presses

In the brewing process of beer, wort filtration is a crucial step. It not only directly determines the clarity and taste of the beer, but also affects the stability and quality of subsequent fermentation. In modern breweries, the application of plate and frame filter presses with high-performance industrial filter cloths is gradually replacing traditional layered filtration or open-air sedimentation methods, becoming a key equipment combination for achieving efficient, stable, and clean wort extraction.

The Process Background of Wort Filtration: What to Filter? Why Filter?

Malt is crushed and mixed with hot water to form “ wort ” which is rich in sugars from starch conversion, proteins, small particles of spent grain, and some suspended solids. If this mixed liquid is directly sent to the fermentation tank, it will not only cause impurity accumulation, but also affect yeast activity, fermentation efficiency, and the final beer flavor. Therefore, it is necessary to use a highly efficient filtration process to separate the spent grain and protein precipitates, obtaining a clear wort liquid.

Traditional wort filtration relies on layers of filter screens and filter tanks, but under the background of increasing production and improving quality standards, its limitations are becoming increasingly prominent. Especially in industrial and large-scale brewing, breweries have chosen plate and frame filter presses + industrial filter cloth This combination not only allows for precise control of filtration efficiency and filtrate clarity, but also has excellent automation, controllability, and hygiene management advantages.

Plate and Frame Filter Press: Brief Description of Structure and Principle

A plate and frame filter press is a batch-operated solid-liquid separation equipment, the core of which consists of alternately arranged filter plates and filter frames. When the wort is fed into the filter press, the filtrate passes through the filter cloth and flows out, while the solid residue is retained on the surface of the filter cloth to form “ filter cake ”。

The advantages of plate and frame filter presses include:

- Controllable filtration pressure adaptable to different wort viscosities;

- Uniform filtration effect the spent grain is tightly distributed;

- Closed structure reducing microbial contamination;

- Filter cloth can be replaced or cleaned lower maintenance costs.

However, these performance advantages are predicated on using a high-performance industrial filter cloth.

Industrial Filter Cloth: The Decisive Factor in Filtration Quality

The filter cloth plays a dual role in the plate and frame filter press: firstly, retaining solid particles such as spent grain and secondly, ensuring smooth filtrate outflow Wort filtration demands much more from the filter cloth than general industrial filtration. Its key performance characteristics include:

1. Food-grade material safety

The filter cloth material must pass food contact certification (such as FDA 、 EU 10/2011 ), commonly used are polyester ( PET ), polypropylene ( PP ), etc., which have good chemical inertness and do not release harmful substances.

2. Precise pore size, high permeability

Wort contains a large number of colloidal substances and small particles, and the filter cloth pore size is generally controlled between 5–15μm It can efficiently retain solids without blocking the liquid flow.

3. Smooth surface, easy to clean

Filter cloth surface treatment processes such as heat setting, calendering, and anti-blocking coatings help with filter cake removal and reuse, facilitating online CIP cleaning, meeting the hygiene management requirements of breweries.

4. High compressive strength, stable structure

The operating pressure of the plate and frame filter press can reach 0.4–1.0MPa The filter cloth needs to have excellent weaving density and tensile strength to withstand frequent mechanical squeezing and washing.

Key Points for Filter Cloth Selection in Brewery Wort Filtration

Different beer types, mashing processes, and malt crushing methods will have different requirements for filtration. For example:

- Craft beers require higher clarity;

- High malt concentration wort requires filter cloth with higher throughput;

- Spent grain with husks has better filterability, while finely ground spent grain is easy to clog the filter cloth.

Therefore, when selecting plate and frame filter cloths, breweries should usually pay attention to the following parameters:

- Material type ( PET 、 PP nylon, etc.);

- Monofilament / Multifilament structure (monofilament is easier to clean, multifilament has better retention effect);

- Pore size range and air permeability;

- Filter cloth weight and thickness;

- Whether it supports customized cutting and edge binding processing.

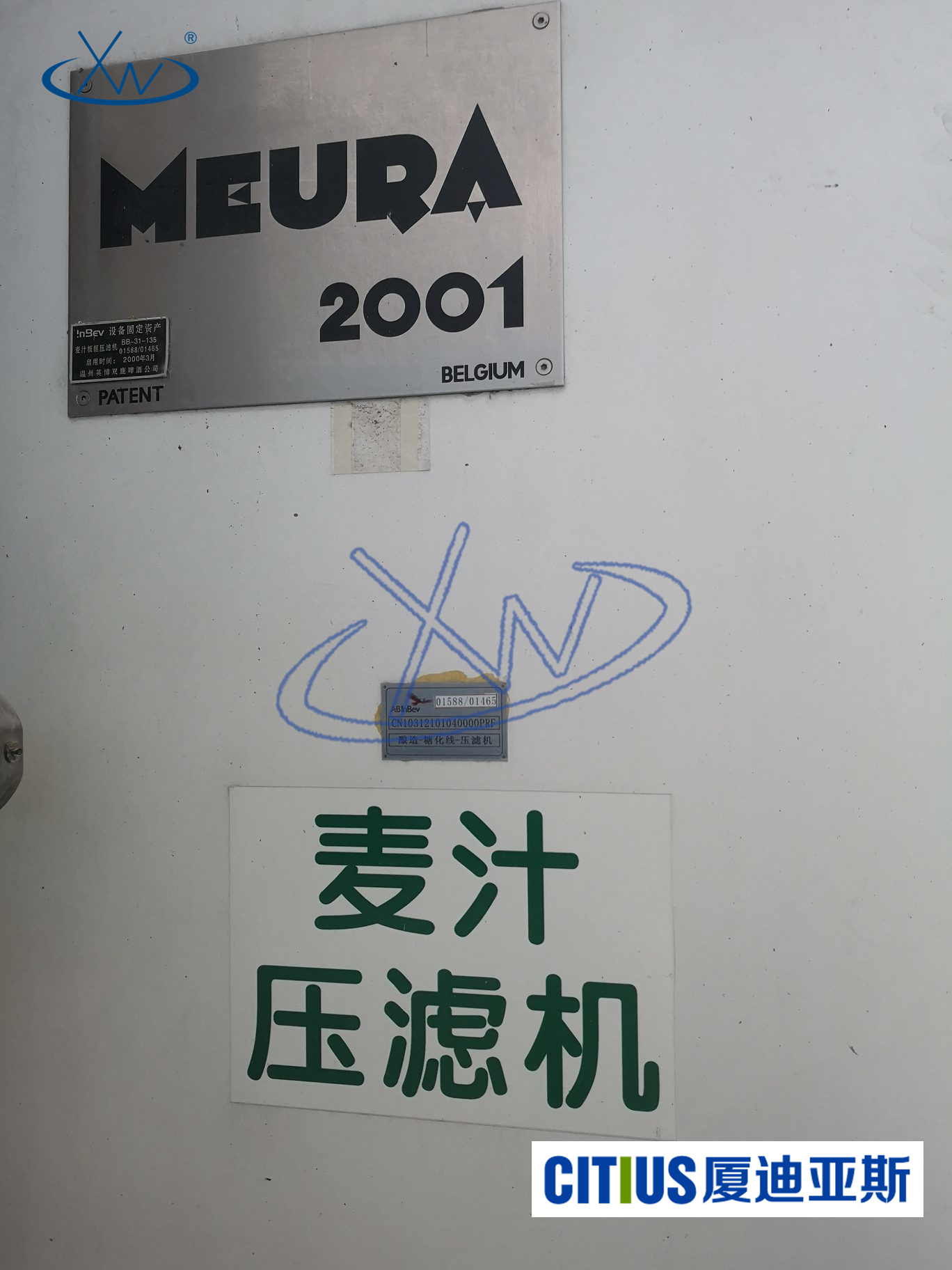

Xiamen Xiadias (Citius) Practical Application of Filter Cloth in Beer Wort Filtration

Taking Xiamen Xiadias (Citius) Filter Material Technology Co., Ltd. as an example, its launched series of food-grade industrial filter cloths have been widely used in the wort filtration process of large breweries at home and abroad. Taking a large brewery with an annual output of 20 ten thousand tons as an example, the factory uses Xiadias (Citius) customized PET filter cloth, with the following characteristics:

- Precise pore size distribution and high retention rate;

- No deformation after multiple cycles of washing and the filter cloth life reaches 300 times or more;

- Excellent filter cake shedding reducing manual intervention;

- Supports high-temperature cleaning with a temperature resistance of 120℃ and can be used with alkali washing and enzyme washing CIP systems;

- Customized according to the filter plate size with a cutting error of ±1mm 。

After nearly two years of continuous use, customer feedback shows that the wort filtration cycle has been shortened from the original 45 minutes to 30 minutes, and the wort yield per unit of malt has increased by 3.5% significantly improving the overall brewing efficiency and wort quality stability of the factory.

Future Trends: More Efficient and Environmentally Friendly Wort Filtration

With the refined development of brewing technology and the increasing demand for green manufacturing, the role of filter cloth in breweries is also constantly evolving. On the one hand, filter cloth materials are moving towards higher cleanliness and stronger corrosion resistance . On the other hand, driven by environmental protection concepts, biodegradable filter cloths and composite materials with ultra-microporous membranes have also become new directions.

In addition, intelligent monitoring systems will be gradually integrated into plate and frame filter press units to monitor the filter cloth status, clogging conditions, residual liquid content, etc. in real time, thereby optimizing the filter cloth replacement cycle and reducing resource waste.

Conclusion: The Value of a Filter Cloth Exceeds Your Imagination

Behind a glass of clear, transparent beer with a pure taste are a series of precise and efficient processes, and the role of filter cloth in this cannot be ignored. It is both the boundary between wort and spent grains, and the link between tradition and modernity.

Choosing a stable and reliable industrial filter cloth is not only a guarantee for the brewing process, but also a deep commitment to beer quality and brand reputation.

If you need filter cloth selection suggestions, sample testing schemes, or industrial filtration solutions suitable for breweries, please contact Xiamen Xiadias (Citius) Filter Material Technology Co., Ltd. We not only manufacture filter cloths, but also deeply understand the technical soul of every drop of beer.

- Industrial filter cloth, filter press filter cloth, plate and frame filter press, application in brewery wort filtration

Filter type: Plate and frame filter press

Application industry: Brewery

Material description: Wort filtration