Industrial filter cloth and filter mesh usage - Application industry: paper mill - Pulp processing

Share to

Detailed Description

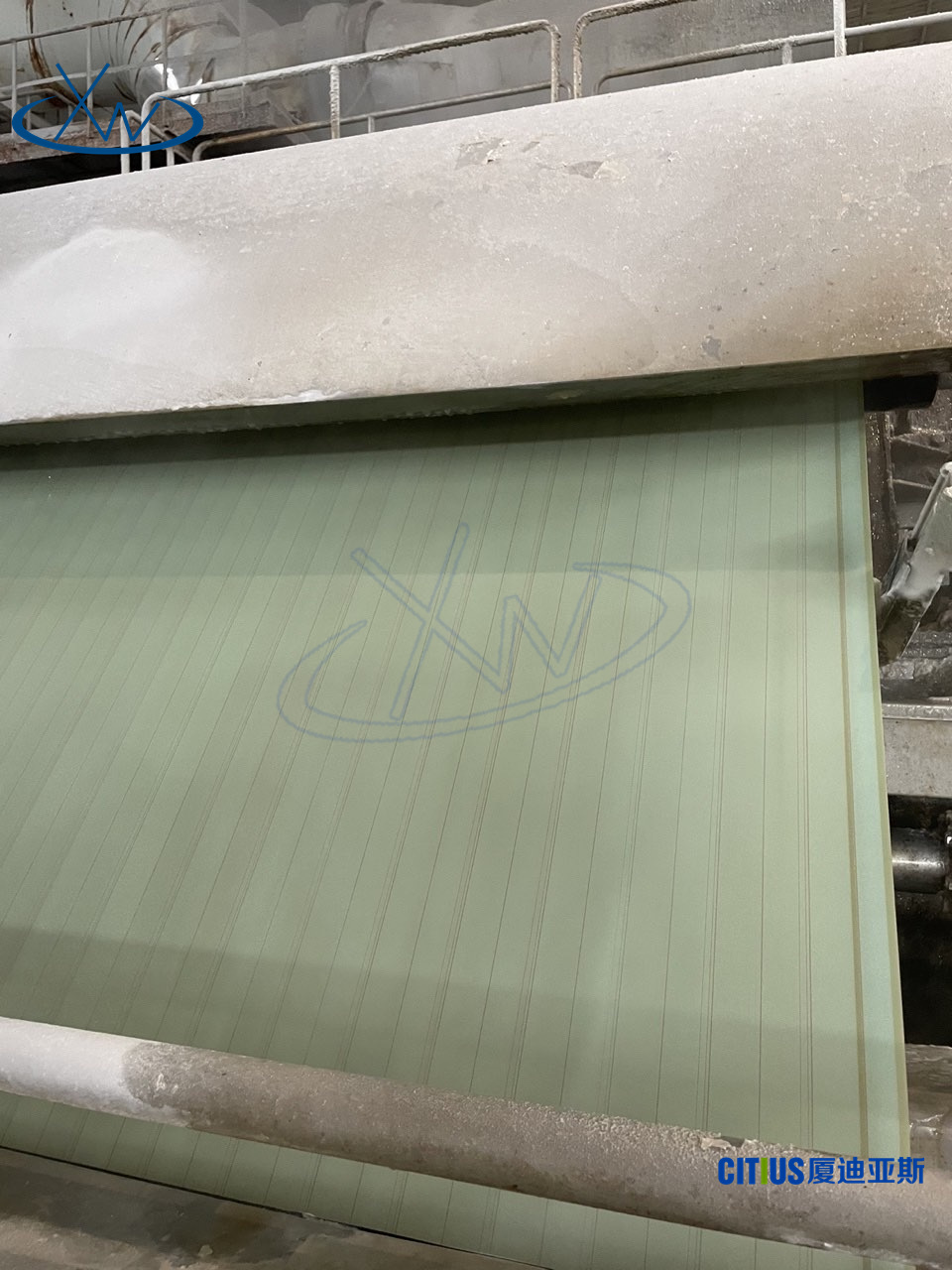

- Industrial filter cloth and filter mesh usage - Application industry: Paper mill - Pulp processing

Filter type: Other equipment types

Application industry: Paper mill

Material description: Pulp

Application analysis of industrial filter cloth and filter mesh in pulp processing in paper mills

—— Technical path centered on solid-liquid separation and dehydration efficiency

With the continuous development of the papermaking industry and the continuous improvement of environmental standards, the solid-liquid separation in pulp processing has increasingly become a key factor affecting production efficiency, energy consumption, and environmental emissions. In the entire pulp preparation, washing, and dehydration process, industrial filter cloth and filter mesh, as the core filtration media, directly determine the operating efficiency of the dehydration system and the quality of the filtered pulp.

This article will start from the pulp processing process and systematically introduce The working principle, adaptable equipment, performance advantages, and selection strategy of industrial filter cloth and filter mesh and, combined with practical cases of different operating conditions in the papermaking industry, in-depth analysis of its technical value and application prospects.

I. Core requirements for filtration media in pulp processing in paper mills

Pulp processing includes steps from raw material pulping, screening, washing, concentration to subsequent dehydration. In these stages, the pulp has High water content, fine fibers, complex composition And other typical characteristics, requiring the filtration equipment to have good solid-liquid separation efficiency and durability.

Industrial filter cloth and filter mesh undertake the following key tasks:

- Rapidly separate free water Achieve pulp concentration increase;

- Intercept fine fibers and impurities Improve pulp purity;

- Ensure continuous and stable operation of the filtration process Reduce clogging and cloth changing frequency;

- Maintain physical strength and filtration performance under high temperature and chemical conditions 。

Therefore, the selection of filter cloth and filter mesh must fully consider the pulp properties, filter equipment type, and target pulp concentration.

II. Matching methods of common filtration equipment and filter cloth

In the pulp processing system of paper mills, industrial filter cloth and filter mesh are mainly used in the following equipment:

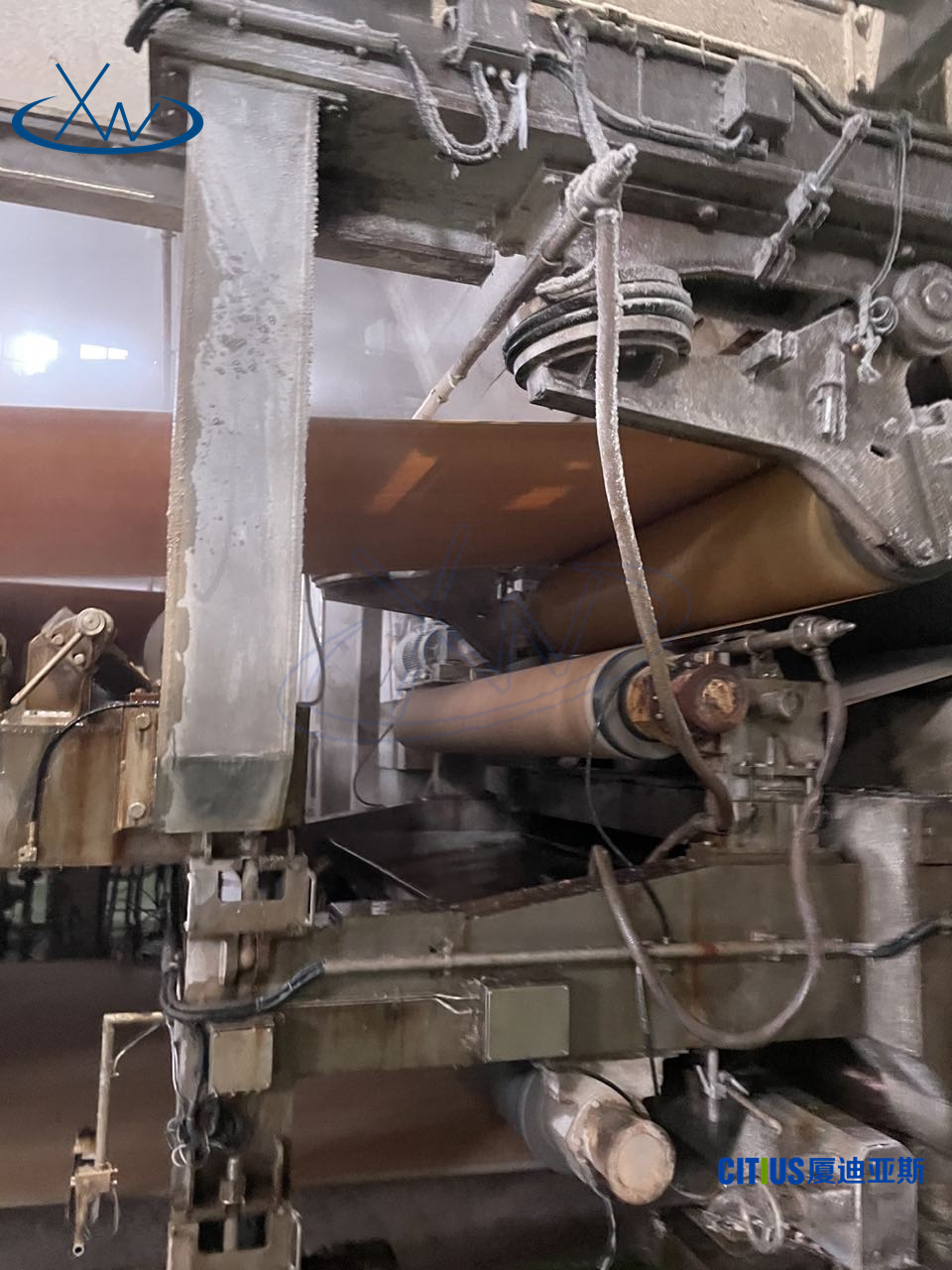

1. Belt press filter ( Belt Press Filter )

- Main uses Pulp concentration and dehydration, waste paper repulping.

- Filter cloth characteristics Uses a double-layer woven structure or spiral dryer net structure, with good tensile strength and permeability, suitable for continuous operation conditions.

- Recommended performance parameters High air permeability, strong hydrolysis resistance, excellent filter cake release.

2. Vacuum belt filter ( Vacuum Belt Filter )

- Main uses : Fine dehydration of high-concentration pulp.

- Filter cloth characteristics : High porosity, high flatness, with high vacuum adsorption efficiency and less damage to the cloth surface.

- Key performance Wear-resistant, acid and alkali resistant, anti-clogging.

3. Gravity concentration equipment

- Main uses Preliminary pulp concentration, fiber recovery.

- Filter mesh characteristics Simple structure, suitable for large flow and primary filtration operations.

- Matching suggestions Use plain weave, open structure nylon or polyester mesh to ensure smooth pulp flow.

III. Filter cloth / Application performance of filter mesh in different pulp processing scenarios

1. Bleached pulp / Chemical pulp processing

Bleached pulp or chemical pulp in the washing and concentration stages are often accompanied by high temperatures and alkaline liquids, which puts high demands on the chemical resistance of the filter cloth. At this time, it is necessary to use Alkali resistance and dimensional stability Filter mesh to ensure that the pulp can be smoothly dehydrated while ensuring fiber retention.

2. Waste paper repulping

Waste paper pulp contains a large amount of short fibers, adhesives, and fine impurities, which easily clog the filter pores and affect continuous production. It is recommended to use Monofilament filter cloth or composite structure mesh To improve anti-clogging ability and extend service life.

3. Paper machine white water recovery system

White water contains a large amount of recyclable fine fibers, which are screened and recovered through high-precision filter mesh, not only saving fiber resources but also reducing wastewater load. Adaptable High-density screen mesh and wear-resistant filter cloth Can achieve good water purification and resource utilization.

IV. Technical advantages of industrial filter cloth

In long-term operation and practical application, high-quality industrial filter cloth shows multi-faceted performance advantages:

Performance dimension

|

Application significance

|

|---|---|

High permeability

|

Improve pulp processing efficiency, reduce energy consumption and pressing time

|

High tensile strength

|

Meets the requirements of high tension operation, extending the service life of the filter cloth

|

Acid and alkali resistant, high temperature resistant

|

Adaptable to the common chemical environments and heat treatment conditions in the papermaking process

|

Good peelability

|

Reduce filter cake residue and improve the efficiency of filter cloth regeneration and cleaning

|

Customizable structural design

|

Meets the differentiated processing needs of different pulp particle sizes and concentrations

|

V. Selection Suggestions and Precautions

✅ Selection Suggestions:

- Determine the filter cloth precision and structural type according to the type of pulp (wood pulp, waste paper pulp, mixed pulp) ;

- Select filter cloths made of hydrolysis-resistant and high-strength fiber materials to improve operational reliability ;

- For multi-stage dehydration systems, configure filter cloths with different structures to match the pressure and concentration changes in each stage ;

- Prioritize filter cloth types with multiple cleaning and reuse capabilities to reduce operating costs 。

✅ Usage and Maintenance Precautions:

- The filter cloth tension should be kept uniform to prevent local deviation or excessive stretching;

- Regularly perform high-pressure water washing or chemical cleaning to prevent fiber blockage;

- The replacement cycle should be adjusted flexibly according to the production frequency and pulp conditions, generally 3~6 months;

- It is recommended to use auxiliary systems such as automatic deviation correction and online cleaning to improve overall efficiency.

VI. Conclusion: Industrial filter cloths promote the upgrading of the papermaking industry towards high efficiency and environmental protection

Against the backdrop of global carbon neutrality and green manufacturing, the papermaking industry is facing the dual pressure of emission reduction and quality improvement. As a key link in the pulp processing process, industrial filter cloths and filter meshes are not merely “ consumables ” ”, but also a carrier of high-performance separation technology.

With the continuous progress of materials science and weaving technology, modern industrial filter cloths are moving towards higher efficiency, more intelligence, and longer lifespan development, becoming an important aid for paper mills to improve pulp processing quality, save operating costs, and optimize environmental indicators. In the future, how to select the most suitable filter cloth scheme based on specific operating conditions will become a key issue for enterprises to enhance their competitiveness.

📞 For technical support or sample testing services, please contact Xiamen Citius (Xiamen Citius) :

- Email: wyl@citius-filter.com

- WhatsApp: +86-13950107241

Official Website : www.citius-filter.com