Plate and frame filter press filter cloth - Industrial filter cloth applications - Industrial and domestic wastewater solid-liquid separation

Share to

Detailed Description

- Plate and frame filter press filter cloth - Industrial filter cloth applications - Industrial and domestic wastewater solid-liquid separation

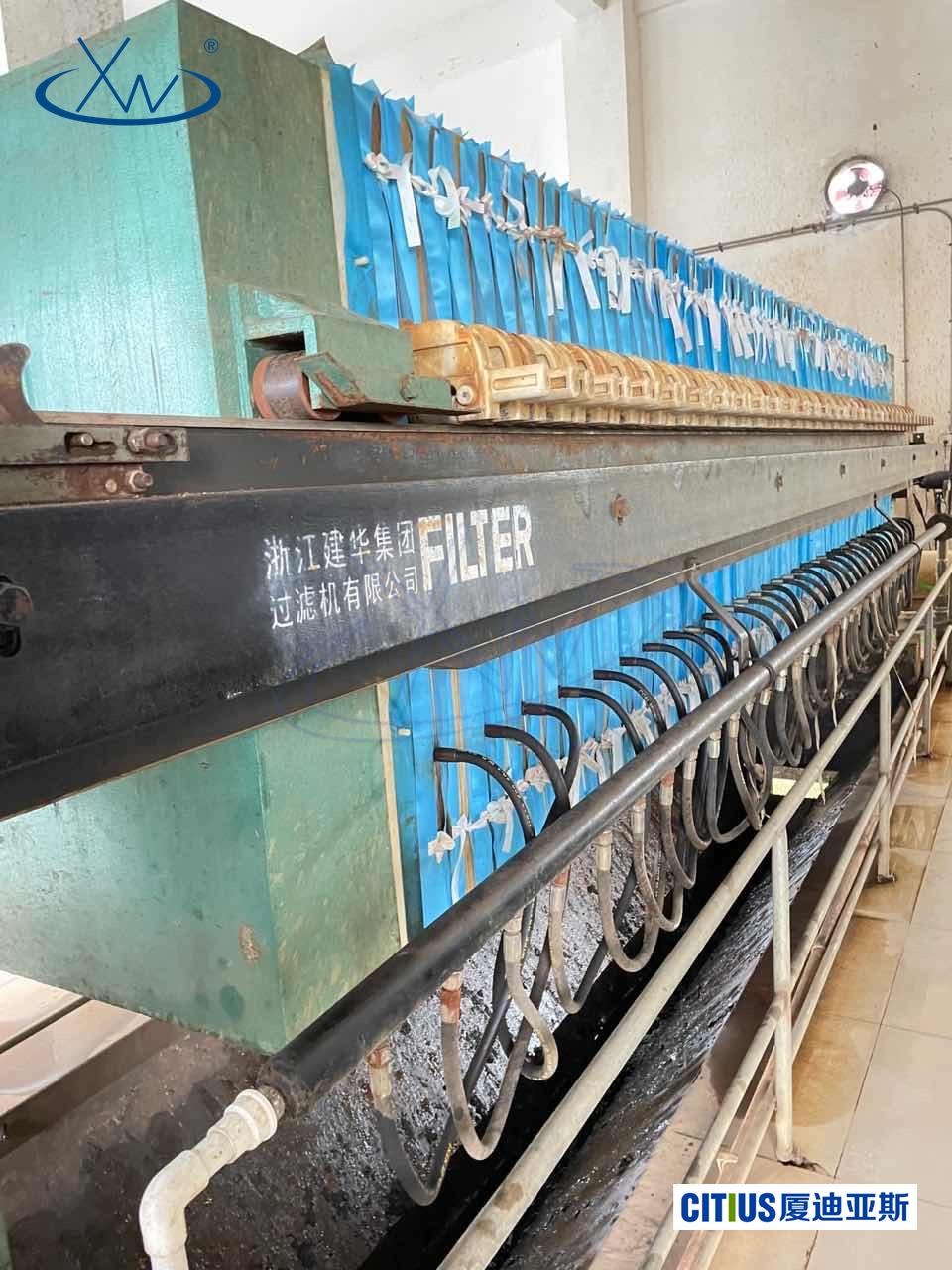

Xiamen Dias Industrial Filter Cloth On-site Operating Case Pictures:

Filter press type: Plate and frame filter press filter cloth

Application industry: Industrial wastewater

Material description: Wastewater

Application of plate and frame filter press filter cloth in industrial and domestic wastewater solid-liquid separation

Solid-liquid separation is a key step in the treatment of industrial and domestic wastewater, directly affecting the subsequent treatment effect and environmental compliance. Plate and frame filter presses, as traditional and efficient solid-liquid separation equipment, are widely used in wastewater treatment plants. The filter cloth, as the core filtration medium of the plate and frame filter press, determines the efficiency of solid-liquid separation and the stability of equipment operation.

I. Plate and Frame Filter Press and its Working Principle

A plate and frame filter press consists of multiple sets of filter plates and frames to form a filter chamber. The filter cloth covers the surface of the filter plate. After the sludge slurry enters the filter chamber, under pressure, the solids are retained by the filter cloth to form a filter cake, and the filtrate flows out through the filter cloth, achieving solid-liquid separation.

II. Characteristics of Industrial and Domestic Wastewater Solid-Liquid Separation

- Industrial wastewater Often contains complex suspended particles, organic matter, and metal ions, requiring the filter medium to have corrosion resistance and wear resistance.

- Domestic wastewater Contains a large amount of organic matter, bacteria, and colloidal substances, requiring the filter cloth to have good filtration accuracy and anti-pollution performance.

III. Application Requirements of Plate and Frame Filter Press Filter Cloth

- High strength and durability

The filter cloth must withstand multiple pressure cycles and mechanical friction, maintain structural stability, and extend service life. - Excellent filtration performance

Uniform pore size distribution ensures effective retention of solid particles and clear filtrate. - Anti-pollution and easy cleaning

The filter cloth surface is smooth to prevent filter cake adhesion, facilitating cleaning and filter cake removal, and improving the continuous operation efficiency of the equipment. - Corrosion resistance

Adaptable to the erosion of acids, alkalis, and chemicals in industrial wastewater, ensuring long-term stable operation of the filter cloth.

IV. Technological Innovation and Optimization Directions

In recent years, filter cloth materials and weaving processes have been continuously improved, such as the use of high-performance polyester fibers and coating treatments, significantly improving the mechanical properties and filtration effects of the filter cloth. At the same time, filter cloths are customized to meet diverse needs based on the characteristics of different wastewater.

V. Practical Application Cases

A large industrial wastewater treatment plant uses an improved plate and frame filter press filter cloth to achieve efficient solid-liquid separation, improving filtrate clarity 30% and extending the service life of the filter cloth 50% The above significantly reduces maintenance costs.

VI. Conclusion

Plate and frame filter press filter cloth, as an important medium for solid-liquid separation of industrial and domestic wastewater, bears the dual tasks of filtration efficiency and equipment reliability. By selecting high-quality filter cloth and optimizing application processes, wastewater treatment efficiency and environmental protection levels can be improved, contributing to industrial green development and improvement of the living environment.