Industrial filter cloth, filter mesh usage - Disc filter press filter cloth model - Aluminum plant alumina refining

Share to

Detailed Description

- Industrial filter cloth and filter mesh usage - Rotary drum filter cloth model - Aluminum plant alumina refining

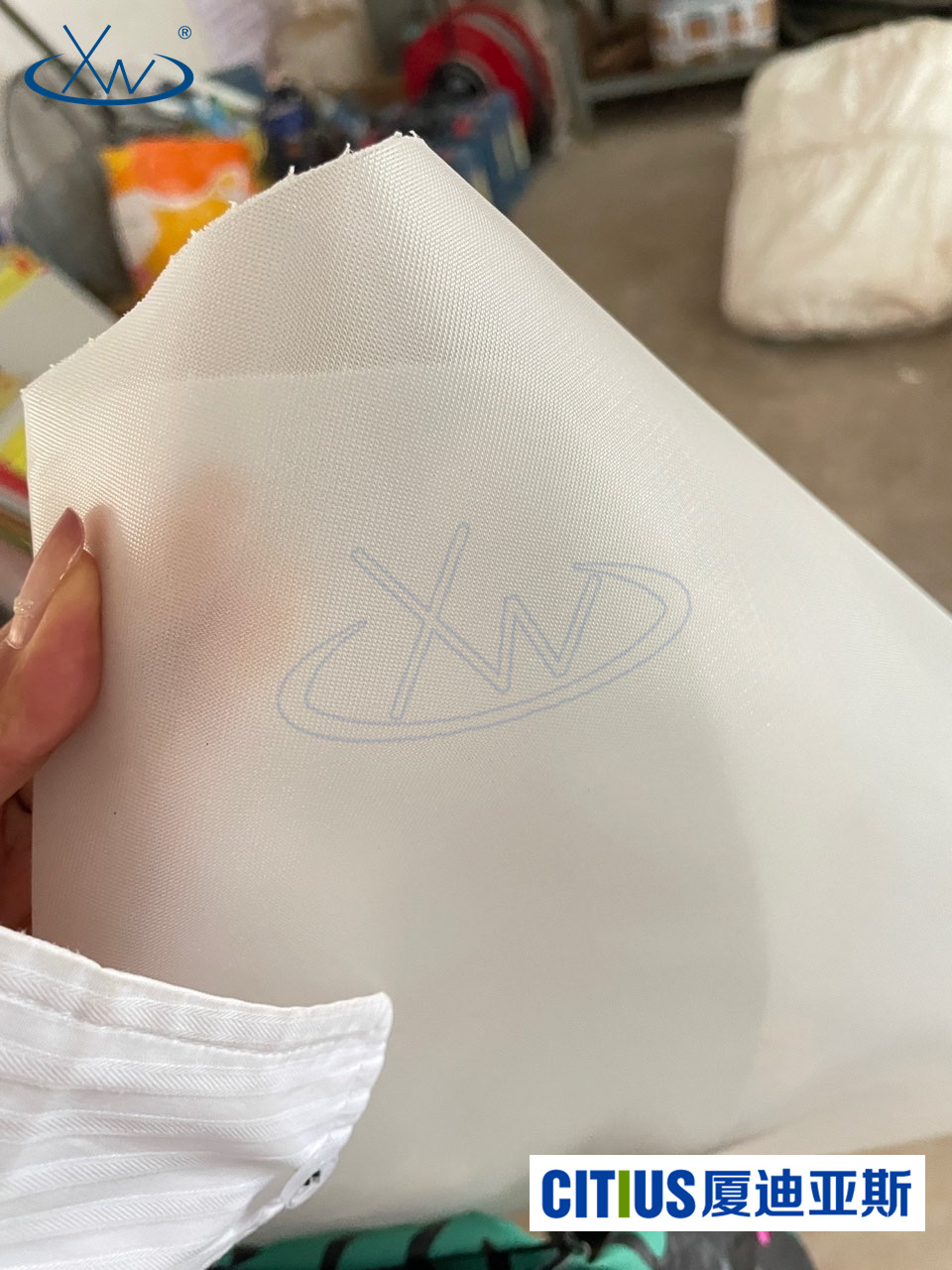

Xiamen Citius Industrial Filter Cloth On-site Operating Case Pictures:

Filter type: Rotary drum filter

Application industry: Aluminum plant

Material description: Alumina

Application of industrial filter cloth and filter mesh in rotary drum filters —— Promoting efficient alumina refining in aluminum plants

In the process of alumina refining from bauxite, solid-liquid separation technology plays an irreplaceable role, especially in key links such as red mud separation, seed washing, and mother liquor purification. The performance of filtration equipment and filter cloth systems directly affects production efficiency, energy consumption costs, and product quality. Rotary vacuum filter Due to its strong continuity, large unit processing capacity, and compact equipment, it is widely used in the alumina industry. At the same time, the supporting Rotary drum filter cloth has also become a key factor in improving the efficiency of the entire system.

I. Analysis of Alumina Refining Process and Filtration Stages

In the mainstream Bayer process, bauxite reacts with high-temperature and high-pressure alkaline solution to produce sodium aluminate solution and red mud residue. In the following stages:

- Red mud separation : Separating the sodium aluminate solution from the unreacted solid residue (red mud);

- Solution clarification and concentration : Removing remaining fine particles;

- Seed washing and separation : Precipitating aluminum hydroxide crystals to improve purity;

- Mother liquor recovery and recycling : Reducing alkali consumption and environmental pressure.

The above processes all involve solid-liquid separation of different particle sizes, placing extremely high demands on the filter cloth's filtration accuracy, dehydration efficiency, corrosion resistance, wear resistance, and operational stability.

II. Rotary Drum Filter Principle and Key Filter Cloth Selection Points

Rotary drum filter overview:

A rotary drum filter consists of multiple sector-shaped filter discs. These disc surfaces periodically rotate and immerse into the slurry tank. Under the action of vacuum negative pressure, they adsorb liquid and form a filter cake. After vacuum dehydration, air blowing backwashing, or scraper discharging, a work cycle is completed.

Key performance indicators of filter cloth:

To achieve excellent filtration effects and stable equipment operation, the filter cloth needs to meet the following aspects:

- Precise pore size control : Filtering fine particles to ensure clarity;

- High air permeability and rapid dehydration capacity : Improving dryness and reducing heat consumption;

- Excellent alkali resistance and temperature resistance : Adapting to high-alkali, high-temperature operating environments;

- Excellent mechanical strength and bending resistance : Anti-pulling, anti-abrasion, ensuring long life;

- Excellent filter cake release and easy cleanability : Improving automation level and reducing downtime;

- Precise cutting and shaping processing : Ensuring that the filter cloth is completely in contact with the sector-shaped disc surface to avoid leakage and wrinkling.

III. Xiamen Citius (Xiamen Citius) Rotary drum filter cloth solutions

As a technologically leading enterprise in China's filtration materials industry, Xiamen Citius (Xiamen Citius) Environmental Filtration Technology Co., Ltd., with 30 years of professional accumulation, provides customized rotary drum filter cloth solutions specifically for the alumina industry. Our products have been widely used in large alumina plants at home and abroad, and have achieved the following significant results:

1. Material advantages:

- Xiamen Citius (Xiamen Citius) Company can research and produce various special-performance monofilament materials according to different application conditions of customers. These materials include: ordinary and high hydrolysis-resistant PET 、 PA ( PA6、PA66、PA610、PA11、PA12 etc.)、 PP (including high-temperature resistant PP )、 PPS 、 PEEK 、core-sheath materials( PA/PET、PPS/PET )。These materials have broadened the application fields of Xiamen Citius (Xiamen Citius) Company's products and solved the requirements of customers' special working conditions for filtration materials.

2. Process processing:

- Laser cutting + Heat setting process to ensure filter cloth dimensional accuracy;

- Edging, sewing, punching, and interface reinforcement processing technologies to enhance installation reliability;

- Support for annular seam joining or one-piece structure for easy maintenance and replacement.

3. Operational advantages:

- Red mud filter cake dryness improvement 3%-5% ,reducing thermal drying energy consumption;

- Filter cloth life is significantly extended, reducing the frequency of replacement ;

- High-efficiency dehydration + Fast unloading ,improving the continuous operation capacity of the entire line;

- Strong filter cloth running stability, good filter cake stripping performance ,effectively reducing manual intervention.

IV. Application Case Summary

In the feedback from typical users in major alumina production areas such as Guangxi, Guizhou, and Shanxi, Xiamen Dias (Xiamen Citius) After using the disc filter cloth kit:

- The service life of the filter cloth has been increased from the original 6 months to 8-12 months;

- System energy consumption decreased by about 6%-10% ;

- The impurity content in the seed crystal washing stage is reduced, and the product purity is significantly improved;

- Filter cloth blockage and mud leakage phenomena are significantly reduced, and the system failure rate is reduced.

V. Customized Service and Technical Support

Xiamen Citius (Xiamen Citius) After nearly 30 years of continuous research and development, the company can provide customers with solutions for filter materials in the solid-liquid separation process, and its research level is leading in China. Xiamen Dias (Xiamen Citius) The company has a technical team with many years of experience in filter material research, and has the most complete filter material research, testing, and pilot production line in China. It can provide customers with customized and personalized services.

Xiamen Citius (Xiamen Citius) With a complete filter material research center and pilot test line, it can provide aluminum plant users with:

- Filtration testing and selection suggestions ;

- Sample development and on-site commissioning services ;

- Filter cloth life analysis and improvement suggestions ;

- On-site installation guidance and training services by technical personnel 。

If you need samples, solutions or case support, please contact Xiamen Dias (Xiamen Citius) Technical Engineering Team:

- 📧 Email: wyl@citius-filter.com

- 📞 WhatsApp: +86-13950107241

- 🌐 Website: www.citius-filter.com