Industrial filter cloth, vertical filter press, starch processing filter press modified starch

Share to

Detailed Description

- Industrial filter cloth, vertical plate filter press, starch processing filter press modified starch

Filter press type: Vertical plate filter press

Application industry: Starch processing

Material description: Modified starch

Application of industrial filter cloth in vertical plate filter press: Empowering efficient dehydration process of modified starch

In the modern starch processing industry, modified starch, due to its wide application in food, papermaking, textile, building materials and other fields, has become one of the important functional materials. Its processing process puts forward higher requirements for solid-liquid separation, especially in the dehydration process, the efficient and stable filter press system has become the key in the production line. Vertical plate filter press, due to its compact footprint, high filtration efficiency, and high degree of automation, is widely used in the production of modified starch. The filter cloth, as the core consumable of the filter press system, its performance directly affects the product quality and operating cost.

Vertical plate filter press: Adapting to the needs of modern modified starch production

The vertical plate filter press adopts a vertically arranged filter plate structure. The filtrate is discharged from top to bottom under the action of gravity and pressure. It has the advantages of fast filtration speed, low moisture content of filter cake, and continuous automatic operation. Compared with traditional horizontal equipment, it is more suitable for small and medium-sized batch and multi-variety modified starch production needs, especially in factories with frequent product formula switching or limited space.

Industrial filter cloth: The key factor determining the dehydration effect

The filter cloth is the separation medium that directly contacts the material during the filtration process. In the dehydration of modified starch, the material has high viscosity and fineness. If the filter cloth is not selected properly, it is easy to cause problems such as slow filtration speed, difficult filter cake separation, high residual liquid and powder.

High-performance industrial filter cloth must have the following characteristics:

- Excellent filtration accuracy and permeability : Ensure efficient retention of modified starch particles while maintaining good filtrate flow rate;

- Good filter cake release : The modified starch particles have a loose structure, and the filter cake is easy to deform. High-smoothness filter cloth helps the filter cake to fall off quickly, avoiding delays in the operation of the filter press;

- Stable chemical resistance and dimensional stability : The modification process may involve acid, alkali or enzyme treatment. The filter cloth needs to have excellent chemical resistance and maintain stable operation for a long period;

- High mechanical strength, anti-stretching and non-deformation : Adapt to the repeated opening and closing and pressure of the vertical plate filter press, prolong the service life of the filter cloth, and reduce the replacement frequency.

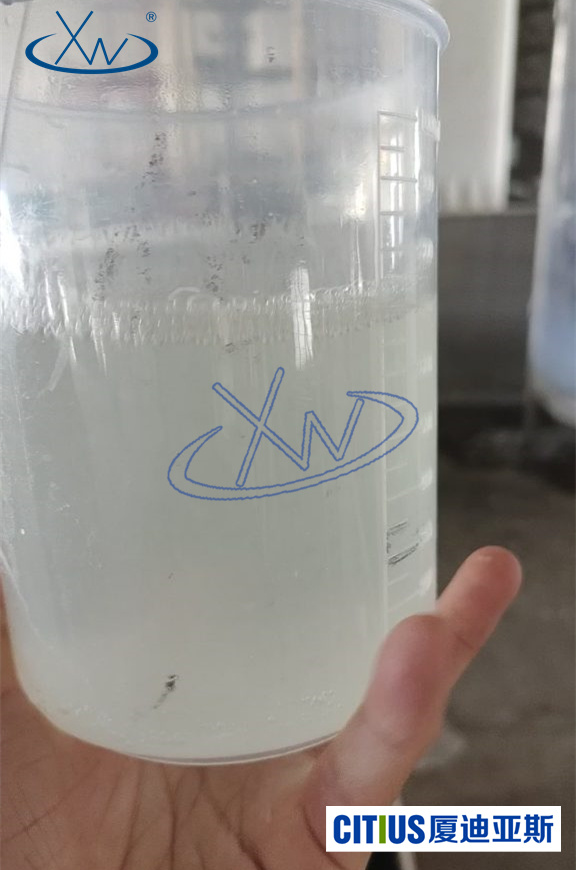

Application example: Assisting efficient dehydration of modified starch

Taking a large starch processing enterprise as an example, after introducing a vertical plate filter press with high-performance industrial filter cloth, the dehydration efficiency has increased 30% Above, the moisture content of the filter cake decreased to 40% Below, the filter cloth replacement cycle was extended from the original 7 Days to 15 Days, effectively reducing operating costs. At the same time, the clarity of the filtrate is improved, which is conducive to the reuse and environmentally friendly discharge in subsequent processes.

Filter cloth selection suggestions and service extension

For starch industry users, according to the type of modification process (such as oxidation, acid treatment, esterification, etc.), slurry concentration, particle size distribution and other parameters, select the appropriate filter cloth structure (single layer, double layer, single filament, composite fabric, etc.) and opening method (punching / No holes, hot melt edges / Seaming). High-end filter cloth suppliers can provide customized services, such as pre-shrinkage treatment, anti-clogging layer treatment, brushing, laser positioning sewing, etc., to help users achieve the best filtration effect.

Conclusion

In today's green, efficient and intelligent development of the modified starch industry chain, the combination of vertical plate filter press and high-performance industrial filter cloth has become a key force to promote the improvement of solid-liquid separation efficiency. Choosing the right filter cloth is not only a guarantee for process optimization, but also an important link to improve product quality and production efficiency. In the future, with the continuous progress of filter cloth materials and weaving technology, the dehydration process in the starch industry will be more efficient, environmentally friendly and intelligent.

If you need further filter cloth selection suggestions or case docking, please contact us:

- 📧 Email: wyl@citius-filter.com

- 📞 WhatsApp: +86-13950107241

- 🌐 Website: www.citius-filter.com