Industrial filter cloth, horizontal vacuum belt filter press for lithium battery new energy acid-cooked slurry processing

Share to

Detailed Description

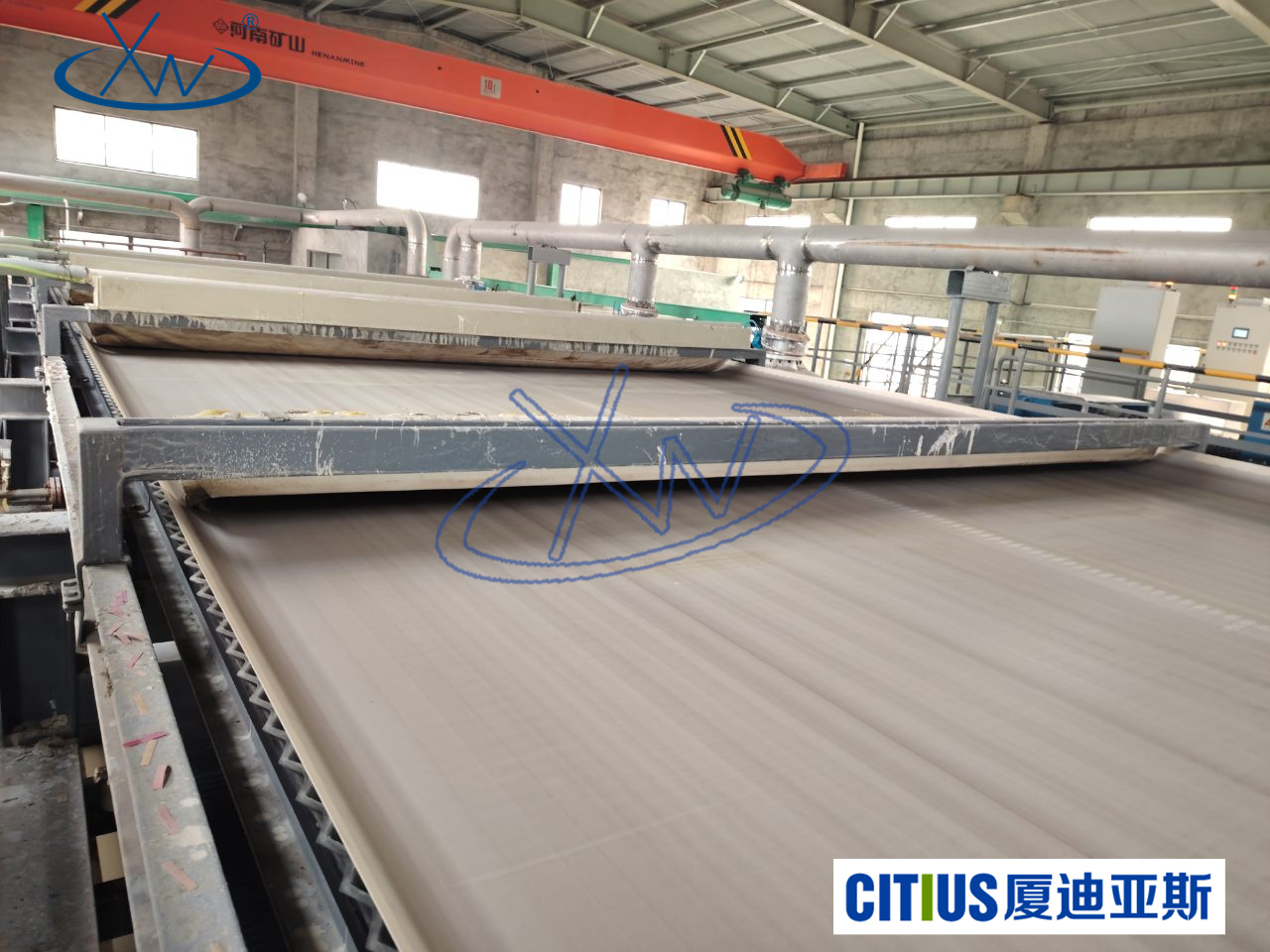

- Industrial filter cloth, horizontal vacuum belt filter for lithium battery new energy acid slurry processing

Filter type: Horizontal vacuum belt filter

Application industry: Lithium battery new energy

Material description: Acid slurry

Filter cloth model: 15T

Application exploration of industrial filter cloth in acid slurry processing in the lithium battery new energy industry

With the continuous growth of global demand for clean energy, the lithium battery new energy industry has developed rapidly. Driven by new energy vehicles, energy storage equipment, and consumer electronics, the lithium battery manufacturing industry chain has gradually improved and become increasingly refined. In the preparation process of lithium battery materials, the processing of acid slurry is one of the key links, involving efficient solid-liquid separation technology, which directly affects product purity, energy consumption level, and environmental compliance. As the core medium for solid-liquid separation, industrial filter cloth plays an irreplaceable important role in the acid slurry processing process.

I. Introduction to acid slurry processing in lithium-ion new energy

In the production process of lithium-ion cathode materials, a common step is to sinter lithium salts (such as lithium carbonate, lithium hydroxide) and other metal oxides (such as ternary material precursors, iron phosphate) at high temperatures to obtain lithium compound materials. In this process, some materials need to be treated with acid first, that is, the raw materials react with a certain concentration of acid solution (such as sulfuric acid, hydrochloric acid, phosphoric acid) to produce acid slurry Acid Slurry 。These slurries have the following characteristics:

- Strong acidity, high corrosiveness ;

- Large fluctuation in solid content, uneven particle distribution ;

- Some slurries have high temperatures and thermal stress ;

- High requirements for filtration efficiency and filter cloth durability 。

Therefore, in the actual industrial processing process, it is necessary to choose industrial filter cloths with stable performance, corrosion resistance, easy regeneration, and high filtration accuracy to ensure the continuity and economy of the entire slurry processing process.

II. Technical challenges facing acid slurry filtration

- Corrosion of materials by strong acidity

The acid solution in the acid slurry is highly corrosive and will quickly corrode acid-resistant fibers, causing fiber breakage, structural degradation, reduced filtration accuracy, and increased cloth breakage rate. - High viscosity of slurry, complex particle distribution

Some slurries have uneven particle sizes and high viscosity, easily clogging the filter cloth pores, forming “ Surface cake ” ”, which seriously affects the permeation rate, lengthens the filtration cycle, and even hinders the operation of the entire machine. - Large processing capacity, high requirements for continuous production

Lithium battery material production is usually continuous and automated, and the requirements for the stable operation capacity of the filtration system are extremely high. Once the filter cloth is frequently replaced or the efficiency decreases, it will lead to system shutdown and increased costs. - High demand for filter cloth regeneration performance

Solid deposits are easily formed on the surface of the filter cloth after acid slurry filtration. If the regeneration is not sufficient, it will affect the filtration effect of the next round and increase maintenance costs.

III. Xiamen Citius (Xiamen Citius) Industrial filter cloth technical solutions

As a leading brand in the research and development and manufacturing of filter material technology textiles, Xiamen Citius (Xiamen Citius) Filter Material Technology Co., Ltd. focuses on the research and development and application of high-performance filter cloths. With 30 years of technical accumulation, it has launched a series of acid slurry-specific filter cloths specially developed for the lithium battery new energy industry, providing a comprehensive solution for acid slurry filtration:

1. Multiple acid-resistant structural design

Citius (Xiamen Citius) Filter cloth uses Special acid-resistant fiber weaving with special treatment and supplemented by Multi-layer structural enhancement technology It can resist corrosion from high-concentration inorganic acids and some organic acids and can operate stably for a long time under conditions such as concentrated sulfuric acid, hydrochloric acid, and phosphoric acid.

2. Fine pore size control and surface treatment technology

For fine particles in the slurry, Citius (Xiamen Citius) Filter cloth through Single filament and composite yarn weaving technology to achieve uniform pore size control and stable filter cake formation. At the same time, the surface uses Anti-clogging coating or physical treatment to reduce particle adhesion and improve permeability.

3. Customized filter cloth structure to match different models

According to the type of filter press used by the customer, such as Belt filter press, horizontal vacuum belt filter, drum filter, vertical filter press, etc. Citius (Xiamen Citius) Provides customized filter cloths with different textures, thicknesses, and tension structures to ensure optimal equipment adaptability.

4. High-efficiency regeneration and cleaning performance

Citius (Xiamen Citius) The filter cloth has excellent regeneration ability and can be restored to its initial performance through backwashing, high-pressure water washing, ultrasound, etc., extending the service life of the filter cloth and reducing operating costs.

IV. Typical application cases

In an acid slurry processing project of a leading ternary material manufacturer, the imported filter cloth previously used had insufficient acid resistance, frequent replacement, and high cost. Citius (Xiamen Citius) After the technical team entered the site, combined with the slurry characteristics and filter operation parameters, a customized high-density composite filter cloth was designed. After on-site testing and verification:

- Filter cloth service life improvement 35% Above ;

- Filter cake moisture content reduction 12% ; significantly improved dehydration efficiency

- More stable system operation, good filter cloth regeneration, and annual comprehensive operating cost reduction exceeding 20 ten thousand RMB 。

Currently, this filter cloth has achieved mass supply and has been promoted to multiple factory bases of this customer.

V. Industry Development Trends and Future Direction of Filter Cloth

With the development of the lithium battery industry chain towards high purity and high precision, acid slurry filtration technology is also moving towards “ intelligent, efficient, and green ” evolution. As the core of the filtration system, the development direction of filter cloth mainly lies in:

- Intelligent matching equipment parameters : In the future, filter cloth will combine sensors and data feedback to achieve real-time monitoring of the filtration status and improve system responsiveness;

- Environmentally friendly materials : Using biodegradable and highly recyclable new environmentally friendly fibers;

- Higher precision and grading filtration capacity : To adapt to the efficient separation of ultra-fine particle slurries;

- Composite functional filter cloth : Combining multiple functions such as filtration, antibacterial, anti-corrosion, and conductivity.

Xiamen Xiadias (Xiamen Citius) As a national high-tech enterprise, it will continue to invest in R&D, continuously innovate material structures and filtration technologies, and contribute to the green and efficient development of the lithium battery new energy industry.

Conclusion

Acid slurry treatment is an indispensable key process in the production of lithium battery new energy materials. Industrial filter cloth is the “ core component ” of the filtration system, and its performance directly affects production efficiency and product quality. Xiamen Xiadias (Xiamen Citius) industrial filter cloth, with its excellent acid resistance, filtration efficiency, and service life, is becoming a reliable partner in the lithium battery industry chain. In the journey towards efficient, green, and intelligent manufacturing, the value of filter cloth is being continuously reassessed, and Xiadias (Xiamen Citius) will continue to lead the industry forward with technological innovation and professional services.

For further information on acid slurry filter cloth models and application cases, please visit Xiamen Xiadias (Xiamen Citius) Official website: www.citius-filter.com Or contact us:

Email : wyl@citius-filter.com

WhatsApp : +86-13950107241