Applications of industrial filter cloth and industrial filter mesh belts: plate and frame filter press, paper pulp pressing in paper mills

Share to

Detailed Description

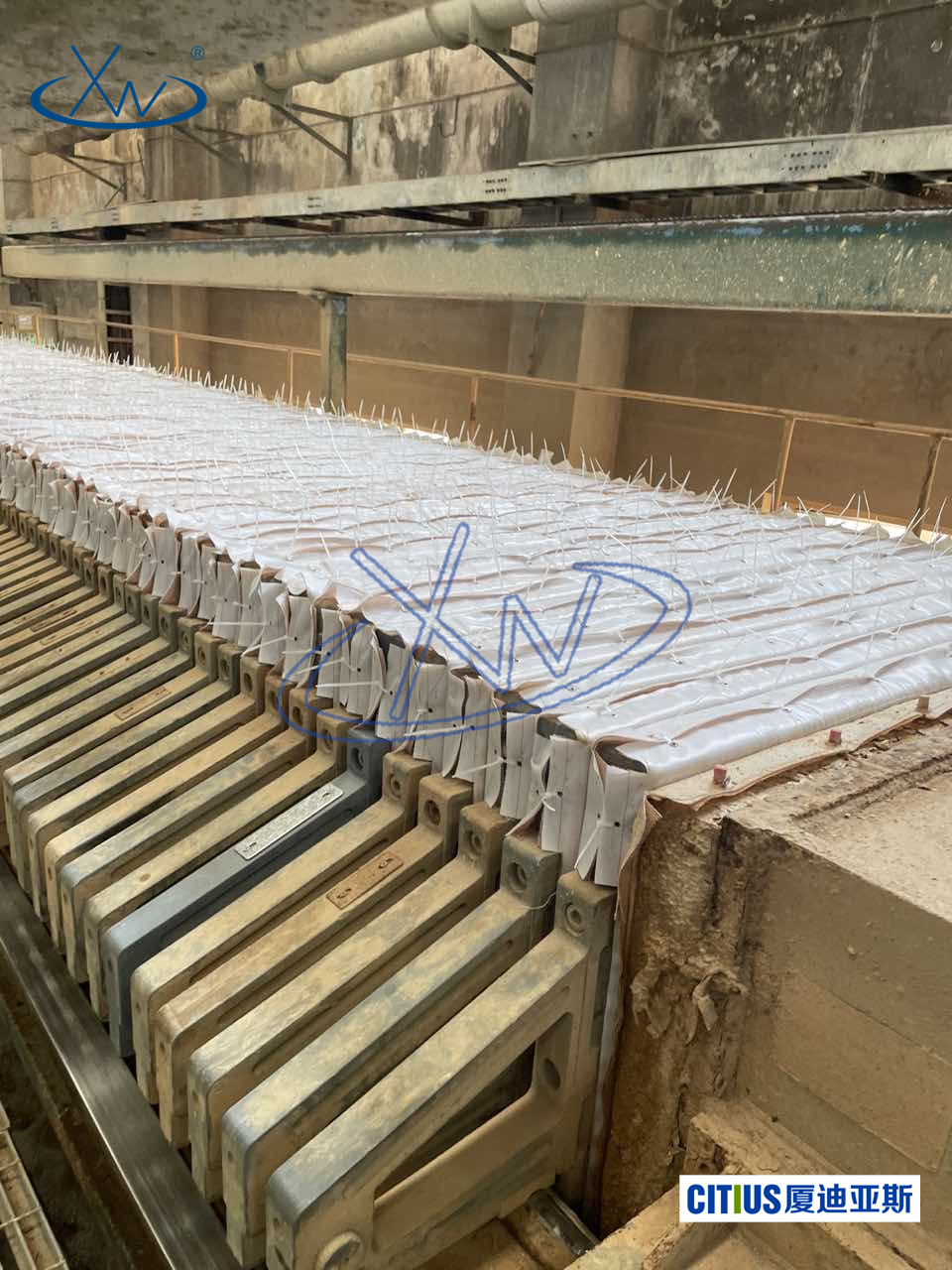

- Industrial filter cloth and filter belt applications: Plate and frame filter press for pulp pressing in paper mills

Filter press type: Plate and frame filter press

Application industry: Paper mills

Material description: Pulp pressing

Filter cloth model: 055

Application of industrial filter cloth and filter belts in pulp pressing in paper mills

—— A key role in the plate and frame filter press process

In modern papermaking, pulp dewatering is crucial for improving production efficiency and paper quality. Plate and frame filter presses are widely used in pulp pressing processes due to their stable dewatering effect and high solid content in the filter cake. Industrial filter cloths and filter belts, as the core media of the equipment operation, directly determine the filtration effect and the stability of the system operation.

Process characteristics of paper pulp dewatering

Pulp is a suspension of plant fibers produced by chemical or mechanical methods. The fibers are long, have high water content, and are loosely structured. Traditional mechanical dewatering is difficult to meet the dual requirements of efficient filtration and high-dryness filter cakes, so most paper mills use plate and frame filter presses for deep dewatering, significantly reducing subsequent drying energy consumption.

Working principle of plate and frame filter press

A plate and frame filter press consists of alternately arranged filter plates and frames to form filter chambers. Under pressure, the pulp enters the filter chambers, the liquid portion passes through the filter cloth and is discharged, and the solids accumulate on the surface of the filter cloth to form a filter cake. As the filtration cycle progresses, the filter cake thickness gradually increases, ultimately achieving pulp concentration and solid-liquid separation.

Application points of industrial filter cloth and belts

- Filtration precision and permeability

Filter cloths used for pulp pressing in papermaking need to have good permeability to ensure rapid drainage, and also have an appropriate pore size to prevent fine fibers from being lost with the filtrate, ensuring the recovery rate. - Compressive strength and wear resistance

During the plate and frame filtration process, the filter cloth must withstand high-pressure squeezing and repeated tensioning, so it requires excellent tensile strength and wear resistance to extend its service life and reduce replacement frequency. - Easy stripping and cleanability

High-quality industrial filter cloth has good filter cake stripping properties for easy cake unloading, and supports various cleaning methods such as backwashing and spraying to improve maintenance efficiency. - Adaptable structural design

According to the pulp concentration and process requirements of different paper mills, Xiamen Citius (Xiamen Citius) can provide single-layer, double-layer, and composite woven structures, adapting to different specifications of filter presses.

Application advantages

- Improved dewatering efficiency : High-quality filter cloth improves filtration speed and dryness, shortening the filtration cycle;

- Stable system operation : Stable belt operation, controllable tension, reducing downtime;

- Reduced operating costs : Durable materials extend the filter cloth replacement cycle, saving labor and maintenance costs;

- Ensuring paper quality : Effectively controlling the leaching of impurities, improving pulp purity and paper consistency.

Xiamen Citius (Xiamen Citius) Solutions

Xiamen Citius (Xiamen Citius) Filter Materials Technology Co., Ltd. has focused on industrial filtration systems for thirty years and has a variety of filter cloth and filter belt solutions suitable for the paper industry. We customize matching filter cloth models according to the different pulp types (chemical pulp, mechanical pulp, mixed pulp, etc.) and filter press parameters of our customers to ensure the best balance between filtration accuracy, operational stability, and economy.

Typical product recommendations:

- High-strength polyester filter cloth, suitable for high-pressure filtration systems;

- Custom-woven filter belts, supporting continuous dewatering of large-area pulp;

- Low-resistance, easy-to-clean filter cloth, suitable for recycled pulp systems.

For more detailed product information, sample applications, or technical advice, please contact Xiamen Citius (Xiamen Citius)(Xiamen Citius) Team:

- Email : wyl@citius-filter.com

- WhatsApp : +86-13950107241

- Website : https://www.citius-filter.com