Applications of industrial filter cloth and filter mesh - plate and frame filter press - lime powder processing in the glass industry

Share to

Detailed Description

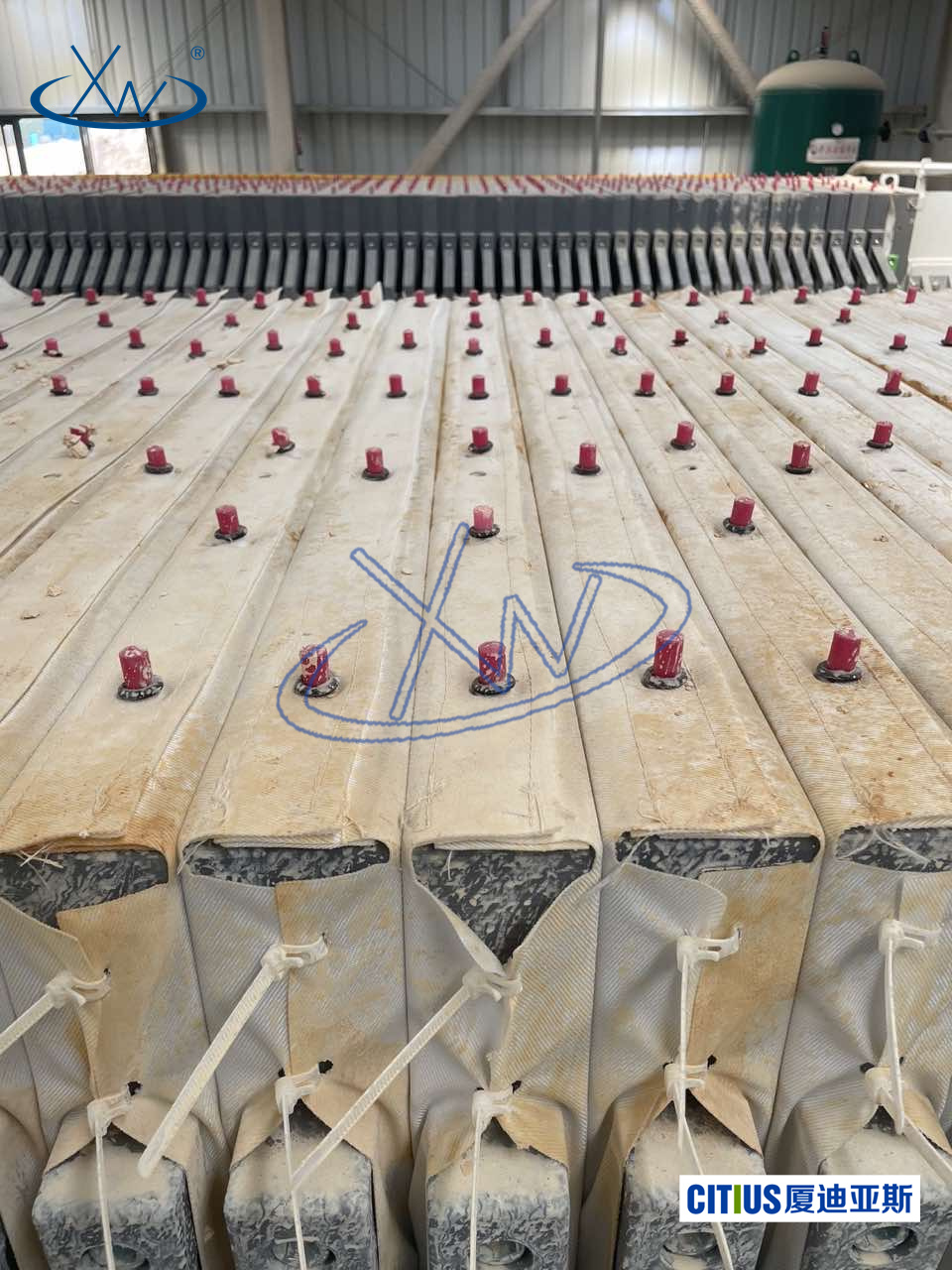

- Industrial filter cloth and filter mesh applications - Chamber filter press - Lime powder processing in the glass industry

Filter press type: Chamber filter press

Application industry: Glass industry

Material description: Lime powder

Filter cloth model used: 002A

Application of industrial filter cloth and filter mesh in the processing of lime powder using a chamber filter press —— Key filtration processes in the glass industry

In modern glass manufacturing, lime powder, as a key fluxing material, directly affects the physical properties and chemical stability of the finished glass product. Solid-liquid separation is a crucial step in the preparation of lime powder. Chamber filter presses, as high-efficiency dewatering equipment, combined with high-performance industrial filter cloths and filter meshes, can significantly improve filtration efficiency and production stability.

I. The role of lime powder in glass production

The main components of glass include quartz sand, soda ash, and lime powder. Lime powder (main component is calcium oxide CaO ) plays the following main roles in glass:

- Reduce the glass melting temperature, saving energy;

- Improve the thermal stability and mechanical strength of the glass;

- Improve water resistance and chemical stability.

To ensure that lime powder performs optimally in the glass formula, the impurity moisture and impurity particles must be controlled through efficient filtration methods 。

II. Advantages of chamber filter presses in lime powder filtration

A chamber filter press is an intermittent, high-pressure solid-liquid separation device, especially suitable for the processing of high-concentration, low-flowability slurries, with the following advantages:

- High filtration accuracy : Achieves complete solid-liquid separation through a multi-layer filter chamber structure and high-pressure feeding method;

- Low filter cake moisture content : Facilitates subsequent drying or direct use in the furnace;

- Good equipment sealing : Suitable for handling corrosive media containing alkaline particles;

- Flexible operation, easy maintenance : Suitable for small and medium-batch production processes.

When processing lime powder in the glass industry, combined with suitable industrial filter cloths and filter meshes, chamber filter presses can achieve efficient and stable dewatering results.

III. Core performance requirements of industrial filter cloths and filter meshes

Filter cloth is the " soul ” " of the filtration efficiency of a chamber filter press, directly determining the cake formation rate, filtrate clarity, and operating costs. When processing lime powder, the requirements for industrial filter cloths and filter meshes are particularly stringent:

1. Good alkali resistance

Lime powder is alkaline, placing higher demands on the chemical stability of the filter cloth material, requiring long-term alkali corrosion resistance.

2. Precise filtration accuracy

The filter cloth pore size must match the lime powder particle size to prevent particle penetration while ensuring high filtrate permeability.

3. Excellent filter cake release

The filtered lime filter cake is often quite sticky, requiring the filter cloth surface to have good cake release properties to prevent filter cloth clogging and wear.

4. High compressive and tensile strength

Chamber filter presses often operate under high pressure, and the filter cloth must withstand tensile and compressive forces for extended periods, requiring good mechanical strength.

5. Easy to clean, strong regenerability

Lime powder is very easy to adhere to filter cloth fibers; high-quality filter cloth must have good water washing recovery to extend the service life and reduce operating costs.

IV. Xiamen Xiadias Solutions

Xiamen Xiadias Filtration Materials Technology Co., Ltd. has been deeply involved in the industrial filtration industry for many years and has provided mature, customized filter cloth and filter mesh solutions for chamber filter presses used in lime powder processing in the glass industry:

- Provides various structural weaving methods to meet the filtration requirements of different dewatering stages;

- Can recommend matching models and pore size designs based on customer site equipment parameters and the physical properties of lime powder;

- Supports personalized processing such as edging, leak prevention, and anti-slippage to improve installation and operational safety;

- Possesses rich experience in serving the glass raw material industry, helping customers reduce operating costs and improve production line stability.

V. Application Cases and Effectiveness Feedback

In multiple glass raw material processing projects, the chamber filter press filter cloth system provided by Xiadias has been successfully applied to the deep dewatering stage of lime powder slurry, and users generally feedback:

- High filter cake dryness, stable production capacity;

- Long filter cloth service life, extended replacement cycle;

- Overall equipment operating efficiency increased 10%-15% 。

VI. Conclusion

With the glass industry's continuous pursuit of high quality and green production, the processing standards for lime powder raw materials are also constantly improving. As one of the key process steps, chamber filter presses, combined with high-performance industrial filter cloths and filter meshes, are gradually becoming the preferred solution for lime powder dewatering and purification. Xiamen Xiadias will continue to provide glass industry customers with more efficient and reliable filtration support through innovative products and customized services.