Applications of industrial filter cloth: Horizontal vacuum belt filter, chemical treatment of phosphogypsum

Share to

Detailed Description

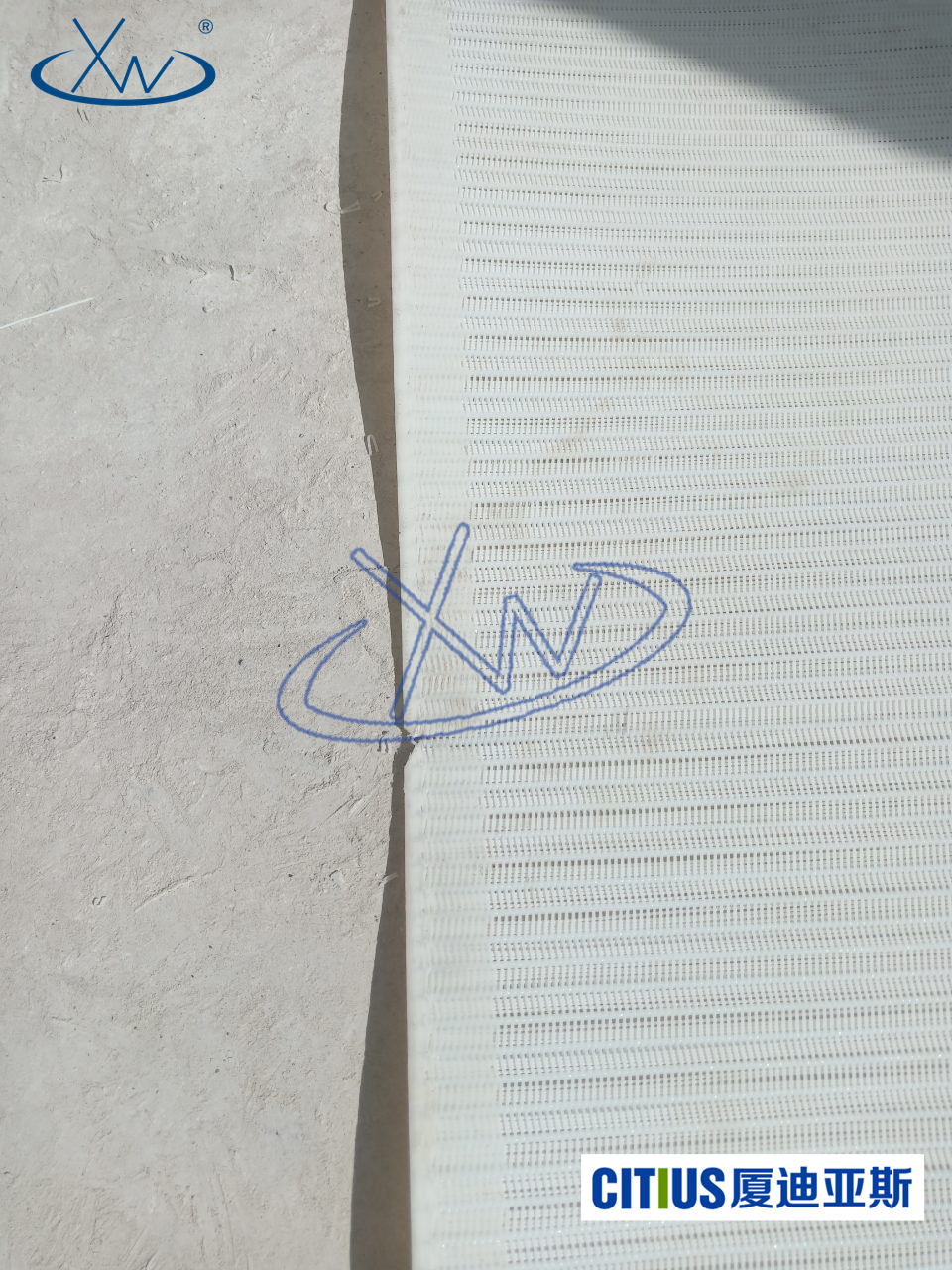

- Application of Xiamen Citius Industrial Filter Cloth in Phosphoric Acid Chemical Processing of Phosphogypsum

Filter Type: Horizontal Vacuum Belt Filter

Application Industry: Phosphoric Acid Chemical Industry

Material Description: Phosphogypsum

Filter Cloth Model: 024, 15P

In the daily production of the phosphoric acid chemical industry, phosphogypsum is produced in large quantities as a byproduct. How to efficiently and environmentally handle phosphogypsum has become a core issue that major phosphoric acid chemical enterprises urgently need to solve. Among many solid-liquid separation processes, Horizontal Vacuum Belt Filter with superior performance Industrial Filter Cloth is gradually becoming the preferred solution for dehydration sections.

This article will focus on the operating characteristics of the phosphoric acid chemical industry, discuss the technical difficulties of phosphogypsum treatment, and how filter material companies represented by Xiamen Citius provide efficient, stable, and green new filtration solutions for the industry through professional filter cloth matching.

I. Sources and Treatment Challenges of Phosphogypsum

Phosphogypsum is a byproduct produced during the production of phosphate fertilizers, yellow phosphorus, and phosphoric acid. Its main component is calcium sulfate dihydrate (CaSO₄·2H₂O), along with a small amount of unreacted phosphates, fluorides, organic matter, and other impurities. Since about 4.5-5 tons of phosphogypsum are produced for every ton of phosphoric acid produced, the annual emissions are enormous.

In actual processing, phosphogypsum presents the following major challenges:

High Water Content Untreated phosphogypsum slurry generally has a water content of over 65%.

Fine Particles, Uneven Distribution Some fine particles affect the permeability of the filter cloth.

Complex Impurities, Strong Viscosity This affects filter cake formation and separation, easily causing cloth surface blockage.

High Environmental Pressure If stable dehydration cannot be achieved, subsequent stacking and resource utilization are difficult to promote.

Therefore, the introduction of efficient dehydration equipment and the improvement of filter cloth performance are key to improving the quality and efficiency of phosphogypsum treatment.

II. Horizontal Vacuum Belt Filter: Core Equipment for High Capacity and Continuous Operation

Compared to traditional intermittent equipment such as filter presses, Horizontal Vacuum Belt Filter it has advantages such as continuous operation, high efficiency, and a high degree of automation, becoming an increasingly important part of phosphogypsum treatment processes.

Its main working principle is:

The phosphogypsum slurry is evenly distributed on the filter cloth;

Negative pressure is generated in the vacuum box below the filter cloth;

The liquid phase is extracted, and the solid phase forms a filter cake on the cloth surface;

Subsequent filter cake washing and dehydration are performed;

The filter cake is removed by a scraper, and the filter cloth enters the cleaning and regeneration cycle.

Outstanding Advantages:

Large-area continuous filtration suitable for high-concentration, high-volume materials like phosphogypsum;

The filter cloth running speed is adjustable adapting to different particle sizes and flow rate conditions;

The system can be configured with multi-stage washing to improve impurity removal rate;

High degree of automation reducing manual intervention.

However, to maximize system efficiency, the choice of filter cloth is particularly important.

III. The Key Role of Industrial Filter Cloth in Phosphogypsum Dehydration

The filter cloth is the core component of the entire filtration system directly determining the filtration accuracy, filtration rate, filter cake quality, and system operating stability. For highly corrosive and strongly viscous byproducts such as phosphogypsum, the filter cloth must have the following characteristics:

1. High Tensile Strength

Horizontal belt machines operate under long-term tension, and the filter cloth must withstand continuous tensile force. Using tightly woven filter cloth with advanced weaving technology can effectively extend its service life.

2. Good Air and Liquid Permeability

This ensures that the filtrate quickly passes through the filter cloth without causing particle penetration or cloth surface blockage, which is the basis for balancing capacity and clear liquid quality.

3. Excellent Filter Cake Release

Phosphogypsum has a certain viscosity, and the filter cake is difficult to detach naturally. It is necessary to choose a filter cloth with a smooth surface, uniform pore size, and easy release to improve unloading efficiency.

4. Corrosion Resistance and Temperature Resistance

In the face of residual components such as phosphoric acid and fluorides, the filter cloth must have excellent chemical stability, acid and alkali resistance, and wear resistance.

IV. Xiamen Citius Filter Cloth Solution: Empowering Green Production with Technology

As a leading Brand in the field of industrial filtration system materials, Xiamen Citius Filter Media Technology Co., Ltd. has long been focused on the research and development and manufacturing of filter cloths for belt filters, and its products are widely used in phosphoric acid chemical, metallurgical, environmental protection, and chemical industries.

For phosphogypsum conditions, Xiamen Citius provides the following solutions:

Special Belt Filter Cloth Using multi-layer weaving technology, ensuring a balance between strength and permeability, suitable for continuous negative pressure operation;

Enhanced peeling layer design Through surface treatment technology, effectively improving the filter cake shedding rate;

Customized punching and edging services Matching customer equipment models, enhancing installation convenience and stability;

Optional automatic cleaning optimization materials The filter cloth is easy to clean and regenerate quickly, ensuring long-term stable operation.

Significant application effects:

Filter cake moisture content reduced to 25-30%

Filter cloth service life extended 25-40%

System annual shutdown maintenance time reduced by more than 30%

Customer Feedback indicates that the filter cloth stability and clarified liquid clarity are significantly superior to conventional products on the market

V. Conclusion: A way out under environmental pressure

With the continuous advancement of the national "dual carbon" strategy and the policy of resource utilization of solid waste, the treatment method of phosphogypsum is shifting from "passive treatment" to "resource utilization and green closed-loop". A highly efficient dehydration system is not only related to the enterprise's operational efficiency but also directly affects its environmental protection compliance and sustainable development.

In this context, the combination of horizontal vacuum belt filter and high-performance industrial filter cloth undoubtedly provides a highly efficient, economical, and environmentally friendly solution for the phosphate chemical industry. Xiamen Citius will continue to leverage its technical advantages in the field of industrial filtration to promote the high-quality utilization and green transformation of industrial by-products such as phosphogypsum.

For more information on filter cloth samples or technical consultation for the phosphate chemical industry, please contact Xiamen Citius Filtration Materials Technology Co., Ltd.:

📧 Email: wyl@citius-filter.com

🌐 Website: www.citius-filter.com

📱 WhatsApp: +86-13950107241