Filter cloth for filter press, plate and frame filter press, wastewater treatment in the dyeing industry

Share to

Detailed Description

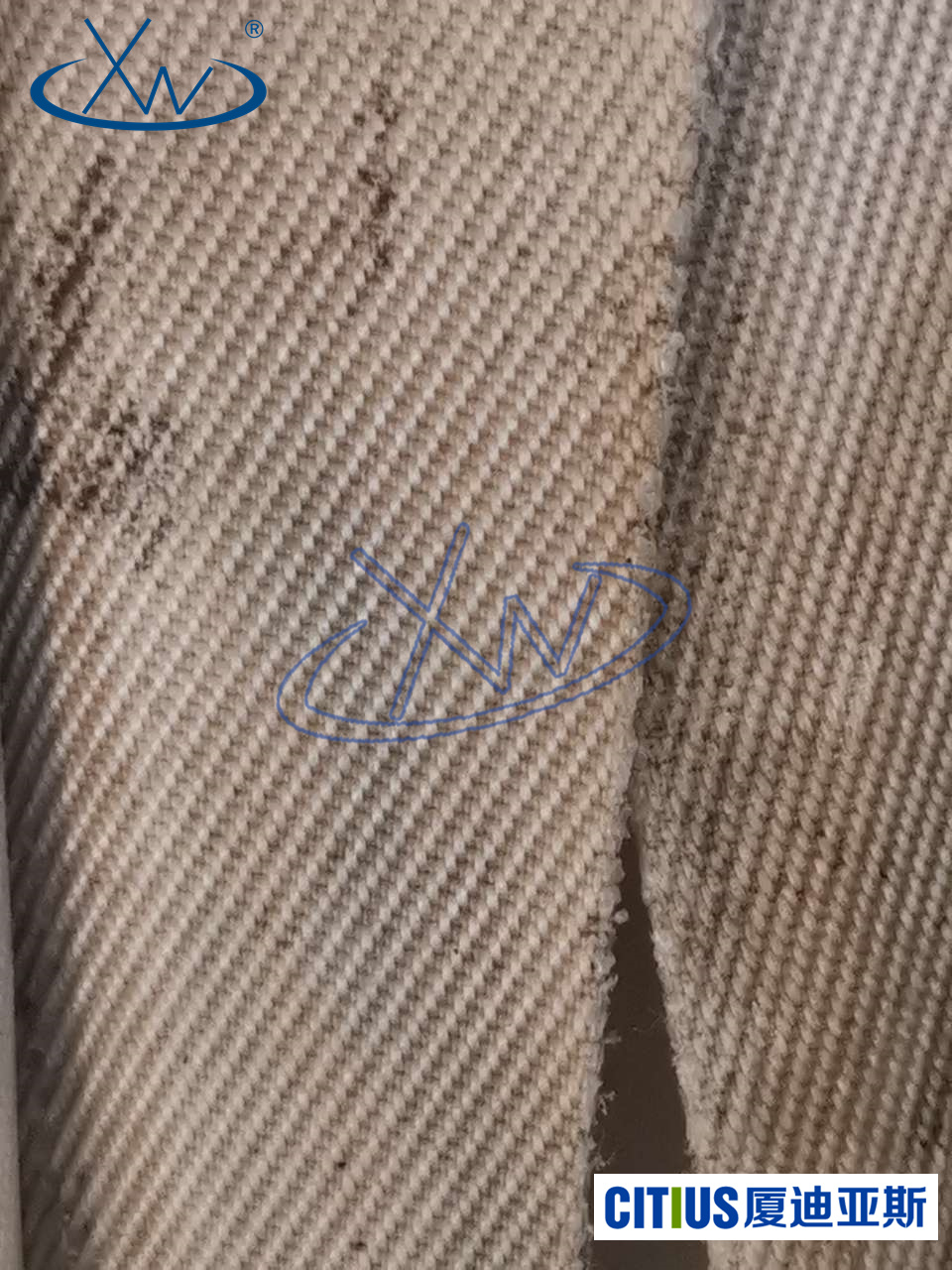

Filter cloth for filter press, plate and frame filter press, wastewater treatment in dyeing industry

Filter press type: Plate and frame filter press

Applied industry: Dyeing

Material description: Dyeing wastewater

I. Introduction: The importance of dyeing wastewater treatment

The dyeing industry discharges a large amount of wastewater during the textile processing, which contains dyes, auxiliaries, suspended solids,COD、BOD and other pollutants, and hashigh chroma, complex chemical composition, poor biodegradabilityand other characteristics. To ensure that wastewater discharge meets environmental protection standards, dyeing enterprises usually use physical, chemical and biological methods for wastewater treatment, among whichplate and frame filter pressAs a key equipment for solid-liquid separation, it uses high-efficiency filter cloth to press filter the sludge to achieve solid-liquid separation and reduction treatment, greatly reducing the water content of sludge and improving the efficiency of subsequent treatment.

II. The core role of plate and frame filter press in dyeing wastewater treatment

1. Efficient solid-liquid separation, reducing sludge moisture content

The plate and frame filter press uses intermittent pressure filtration to concentrate and dewater the sludge produced during dyeing wastewater treatment.

- Through the efficient filtration of the filter cloth, the fine suspended matter and solid particles are effectively retained on the surface of the filter cloth to form a filter cake.

- The filter cloth has excellent water permeability, which helps to quickly discharge the filtrate, reduce the moisture content of the filter cake, and reduce the burden of subsequent sludge drying and incineration treatment.

2. Adapting to the characteristics of complex wastewater and improving filtration efficiency

The composition of dyeing wastewater is complex, and substances such as dyes, surfactants, and heavy metals may cause blockage and corrosion of the filter cloth. The plate and frame filter press can operate stably in different process stages (such as flocculation sedimentation and sludge concentration), and the filter cloth can choose suitable models according to the composition of wastewater to ensure stable and reliable treatment effect.

3. Achieving sludge reduction and reducing operating costs

The water content of the filtered sludge can be reduced to50% or less, the sludge volume is greatly reduced, reducing the pressure on subsequent treatment and reducing the cost of sludge transportation and treatment.

III. Technical advantages of filter press filter cloth in dyeing wastewater treatment

1. Efficient filtration, maintaining permeability

Dyeing wastewater contains a large amount of fine particles and colloidal substances, which easily block the pores of the filter cloth. High-quality filter cloth adoptsmultilayer structure weaving processIt has a smooth surface and is not easy to block, maintaining long-term permeability.

- Precise pore size distribution:It can effectively retain fine particles, reduce the turbidity of the filtrate, and improve the filtration accuracy.

- Strong anti-pollution ability:The surface of the filter cloth is specially treated to prevent dye particles and organic matter from adhering, extending the service life of the filter cloth.

2. Strong corrosion resistance and chemical resistance

Dyeing wastewater often contains acidic, alkaline and oxidizing chemicals, which are corrosive to filter cloth materials. High-performance filter cloth usesacid-resistant, alkali-resistant and oxidation-resistant materialsIt can maintain stable performance in a highly corrosive environment for a long time.

3. Excellent stripping performance, easy to remove filter cake

The dyeing sludge after pressing often has high adhesion and is easy to adhere to the surface of the filter cloth, making it difficult to regenerate the filter cloth. The surface of high-quality filter cloth isanti-adhesion treatmentto ensure easy filter cake stripping, reduce the frequency of filter cloth cleaning, and improve the continuous operation capacity of the equipment.

IV. Filter cloth selection points: Matching dyeing wastewater treatment needs

1. Pore size and filtration accuracy matching

Select the appropriate filter cloth pore size according to the particle size of solid particles in dyeing wastewater.

- Too large a pore size may cause the filtrate to be turbid and the filtration effect is poor;

- Too small a pore size will reduce the filtration speed and increase the risk of blockage.

2. Corrosion resistance and durability

The pH of dyeing wastewater varies greatly, and the filter cloth needs to haveresistance to strong acid and strong alkali environmentscharacteristics, while having good oxidation resistance and anti-swelling ability to avoid structural changes during long-term use.

3. Filtration speed and stripping performance

In the dyeing sludge treatment process, the filter cloth should havefast filtration abilityAt the same time, the filter cake stripping performance should be excellent to reduce the pollution of residues to the filter cloth and extend the service life.

V. XiamenXiamen CitiusFilter Cloth——Promoting dyeing wastewater treatment

Asa leading brand in the research and manufacturing of filter material (mesh belt) technical textiles,XiamenXiamen CitiusFilter Material Technology Co., Ltd.provides efficient and durable plate and frame filter press filter cloth solutions for the dyeing industry.

Core Advantages:

✅ High Filtration Accuracy:Using advanced weaving technology and uniform pore size distribution to ensure solid-liquid separation effect.

✅ Strong Acid and Alkali Resistance:Adapts to the highly corrosive environment of dyeing wastewater and maintains stable performance for a long time.

✅ Anti-Clogging, Easy to Peel:Special surface treatment reduces sludge adhesion and improves filter cloth regeneration efficiency.

✅ Customized Service:According to the characteristics of dyeing wastewater, provide exclusive filter cloth models to ensure the best filtration effect.

VI. Conclusion: The Key to Improving Wastewater Treatment Efficiency in the Dyeing Industry

In the wastewater treatment of the dyeing industry, the filter cloth of the plate and frame filter press plays a crucial role. High-performance filter cloth can not only improve filtration efficiency, reduce equipment maintenance costs, but also effectively extend the service life of the filter cloth. XiamenXiamen CitiusWith its rich industry experience and continuous technological innovation, it provides high-quality filtration solutions for dyeing enterprises, helping enterprises achieve efficient and environmentally friendly production goals.