Filter cloth for filter press, plate and frame filter press, brick industry processing of calcium oxide

Share to

Detailed Description

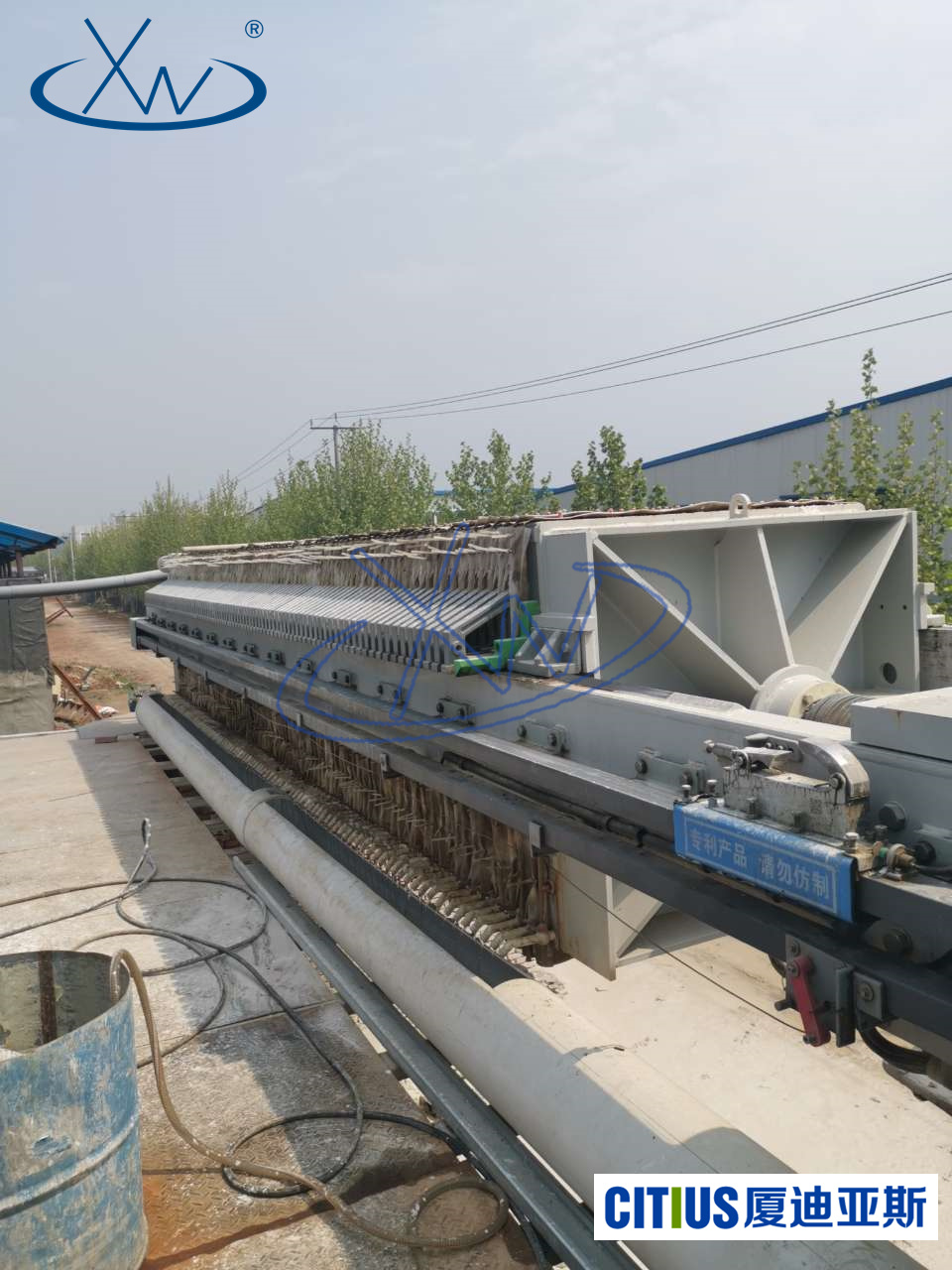

Filter cloth for filter press, plate and frame filter press, processing calcium oxide in the brick making industry

Filter press type: Plate and frame filter press

Application industry: Brick making

Material description: Calcium oxide

I. Introduction: The processing needs of the brick making industry and calcium oxide

In the modern brick making industry, calcium oxide (CaO) is a common raw material, often used to improve the hardness and durability of brick blanks. However, in the brick making process, due to the large fluctuation in the calcium oxide content of the raw materials, it needs to be properly processed to remove excess impurities and ensure the stable quality of the finished bricks. Plate and frame filter presses, due to their efficient solid-liquid separation capabilities, have become key equipment for processing calcium oxide slurry, while the selection of high-performance filter cloth directly affects the filtration effect and production efficiency.

II. The core role of filter cloth for filter press in calcium oxide processing

1. Improvement of solid-liquid separation efficiency

The plate and frame filter press effectively separates solids and liquids in calcium oxide slurry through pressure, and the filter cloth, as the core filtration medium, determines the separation efficiency based on its pore size, surface structure, and anti-blocking performance.

- The smooth surface of the filter cloth makes filter cake easy to peel off, reducing cleaning frequency and improving continuous operation efficiency.

- Reasonable pore size distribution can prevent the clogging of filter cloth pores by fine calcium oxide particles, ensuring smooth filtration.

2. Stability in handling high-concentration slurry

Calcium oxide slurry has high viscosity and fine particles, and is easily deposited on the surface of the filter cloth, leading to a decrease in filtration efficiency. For this characteristic, the filter press filter cloth should have good hydrophobicity and air permeability to ensure stable separation effect under high load.

3. Filter cloth regeneration and service life

Calcium oxide slurry has certain alkalinity and corrosiveness, and long-term use will cause the performance of ordinary filter cloth to deteriorate. Therefore, high corrosion resistance and alkali resistance filter cloth materials are particularly important. Using filter cloth with strong alkali resistance and high mechanical strength can effectively extend the service life of the filter cloth and maintain excellent regeneration characteristics, reducing replacement frequency and maintenance costs.

III. Application advantages of plate and frame filter press in calcium oxide processing

1. High filtration accuracy, low filter cake moisture content

The plate and frame filter press uses a pressure filtration method, which can form a filter cake in a short time and effectively reduce the moisture content of the filter cake, thus reducing the subsequent drying cost and improving production efficiency.

2. Flexible equipment operation, strong adaptability

The plate and frame filter press is suitable for processing calcium oxide slurry with different concentrations and particle sizes. By adjusting the filter cloth model and filter press parameters, it can flexibly adapt to different production needs.

3. Sustainable operation, reducing manual intervention

With an automatic cleaning system and high-efficiency filter cloth, the regeneration effect is good, greatly reducing downtime maintenance time and achieving continuous production.

IV. Key points of filter cloth selection: Matching the needs of the brick making industry

1. Pore size matching: Anti-clogging, improving filtration speed

Calcium oxide slurry particles are fine, so filter cloth with moderate pore size and good water permeability should be selected to prevent fine particles from clogging the filter cloth and affecting the filtration effect.

2. Balancing alkali resistance and wear resistance

Since calcium oxide has certain alkaline properties, the filter cloth needs to have good alkali resistance and wear resistance to prevent the filter cloth from losing its filtration performance during long-term operation.

3. High-strength structure, strong durability

Considering the high-intensity production needs of the brick making industry, the filter cloth needs to have high tensile strength and mechanical stability to extend its service life and reduce the replacement frequency.

V. Xiamen Citius filter cloth - assisting calcium oxide filtration in the brick making industry

Asa leading brand in the research, manufacturing and technology of industrial textile products - filter materials (conveyor belts) in ChinaXiamen Citius Filtration Materials Technology Co., Ltd., with 30 years of industry experience, provides high-performance plate and frame filter press filter cloth solutions for the brick making industry.

Advantages:

- High filtration accuracy:The special weaving process ensures efficient separation of calcium oxide particles, preventing particle leakage.

- Excellent alkali resistance:Corrosion-resistant materials are used to effectively resist the alkaline erosion of calcium oxide.

- Good release performance:Filter cake is easy to peel off, improving the operating efficiency of the filter press.

- Customized service:Provides professional customized filter cloth solutions according to user needs to ensure optimal matching.

VI. Conclusion: The key to improving production efficiency in the brick making industry

Filter cloth for filter press plays an irreplaceable role in the processing of calcium oxide in the brick making industry. Choosing high-quality filter cloth can not only improve filtration efficiency and reduce production costs, but also improve equipment service life. Xiamen Citius, with its rich industry experience and technological innovation capabilities, helps brick making enterprises achieve more efficient and stable production goals.