Industrial Filter Cloth Application - Centrifuge - Cathode Materials in Lithium Battery Electronics Industry

Share to

Detailed Description

- Industrial Filter Cloth Application - Centrifuge - Cathode Materials in Lithium Battery Electronics Industry

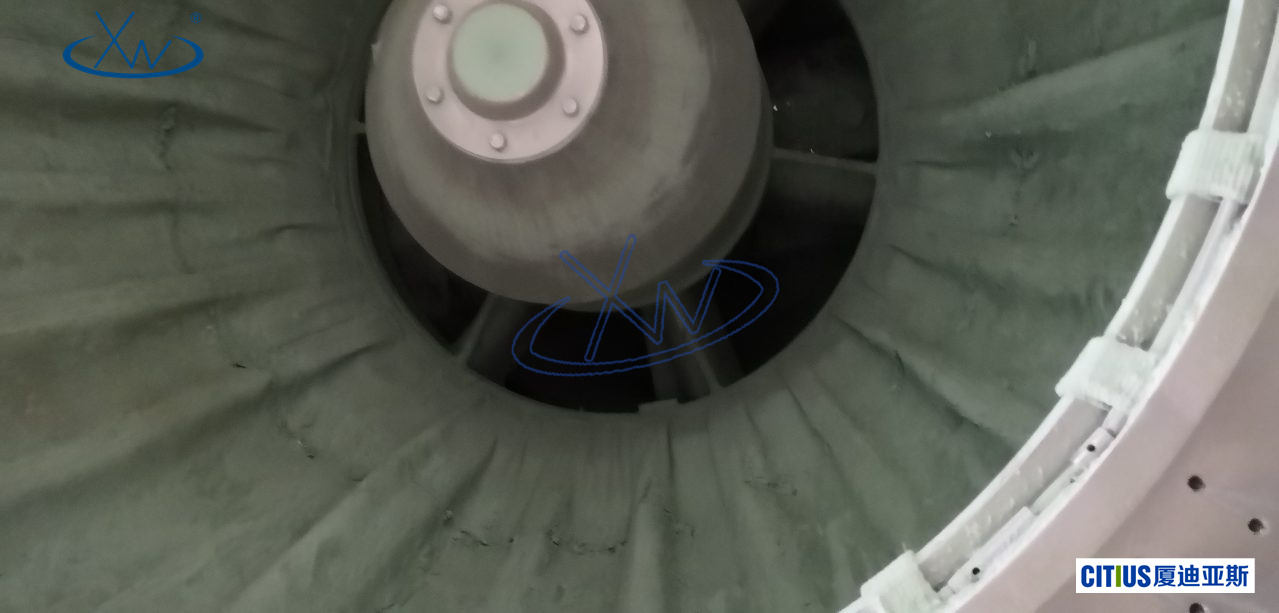

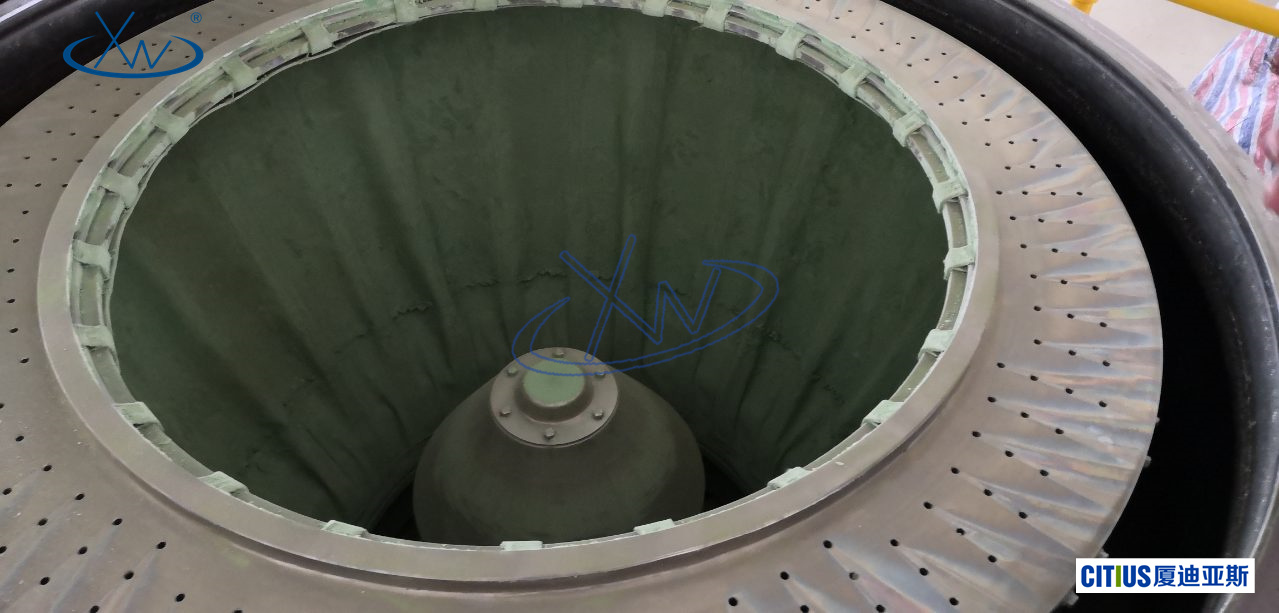

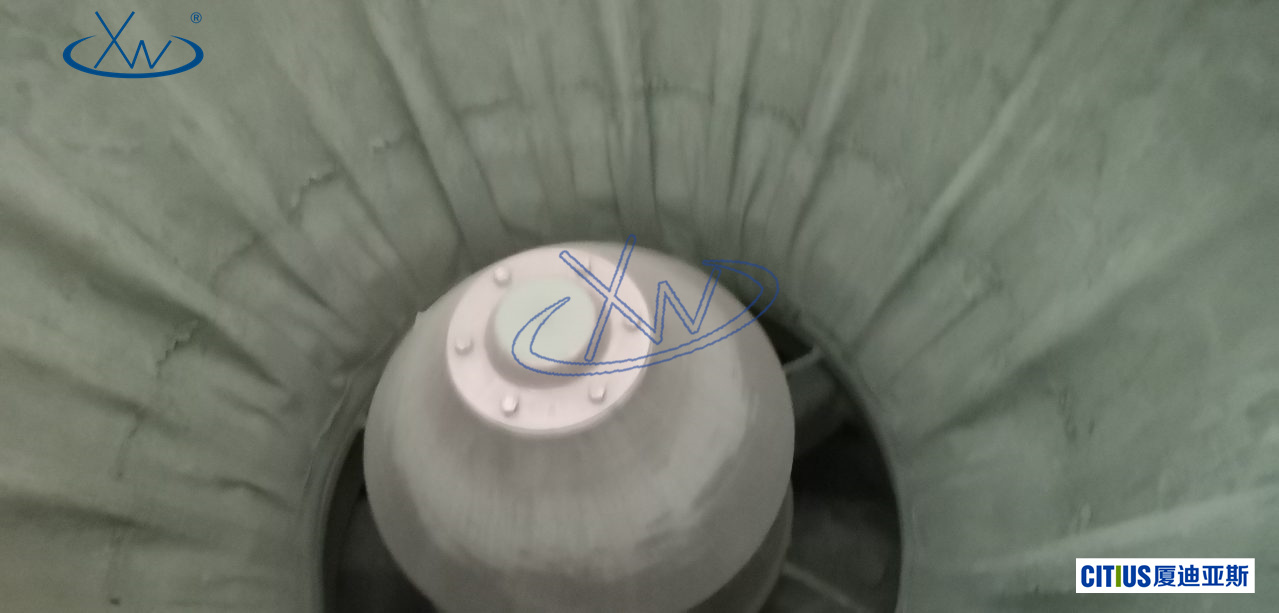

Type of Filter Machine: Centrifuge

Application Industry: Lithium Battery

Description of Processed Material: Cathode Materials

In the production process of cathode materials in the lithium battery electronics industry, the application of industrial filter cloth in centrifuges is crucial. With the continuous growth of the lithium battery market, the quality and production efficiency of cathode materials have become the focus of industry attention. Centrifuges play a vital role in the purification and dehydration of cathode materials, and efficient filter cloth is key to ensuring the stable operation of the centrifuge.

Application of Industrial Filter Cloth in Centrifuges:

- High Efficiency Filtration:In the production process of lithium battery cathode materials, centrifuges need to separate fine solid particles from liquids. Industrial filter cloth can efficiently filter solid particles, ensuring the filtrate is pure and improving separation efficiency.

- High Temperature Resistance:In the production process of cathode materials, temperatures may be high, especially in certain sintering or roasting processes. The application of industrial filter cloth in centrifuges must withstand high-temperature environments to prevent material deformation or damage.

- Chemical Stability:Lithium battery cathode materials may contain acidic or alkaline chemicals, so the chemical stability of the filter cloth is crucial. Choosing the right filter cloth ensures it can be used long-term in highly corrosive environments.

- Strong Adaptability:There are various types of lithium battery cathode materials, and the filter cloth needs to have good adaptability. Whether processing lithium cobalt oxide, nickel-cobalt-manganese ternary materials, or other types of cathode materials, the filter cloth should adapt to different processing conditions to ensure production stability.

- Filter Cake Release Performance:Due to the strong adhesion of the filter cake produced by the centrifuge when processing lithium battery cathode materials, special consideration needs to be given to the filter cake release performance when selecting filter cloth, ensuring that the filter cake is easy to remove after filtration, reducing equipment maintenance difficulty.

Xiamen Xadia(Citius)Application in Filtering Lithium Battery Cathode Materials:

Xiamen Xadia(Citius)Industrial filter cloth, with its excellent filtration performance and durability, has been widely used in the lithium battery industry, especially in the production process of cathode materials. The company provides customized services based on different process requirements, offering filter cloth with excellent breathability, high-temperature resistance, and corrosion resistance for centrifuge needs. Xadia's filter cloth not only improves the production efficiency of lithium battery cathode materials but also effectively extends the lifespan of the equipment.(Citius)By precisely selecting suitable industrial filter cloth, it can ensure that the centrifuge efficiently removes unwanted solid particles during processing, improving the efficiency of the production process and the purity of the materials, providing a solid guarantee for the production of lithium battery cathode materials.

通过精确选择适合的工业滤布,可以确保离心机在处理过程中能够高效地去除不需要的固体颗粒,提高生产过程的效率和材料的纯度,为锂电池正极材料的生产提供坚实的保障。