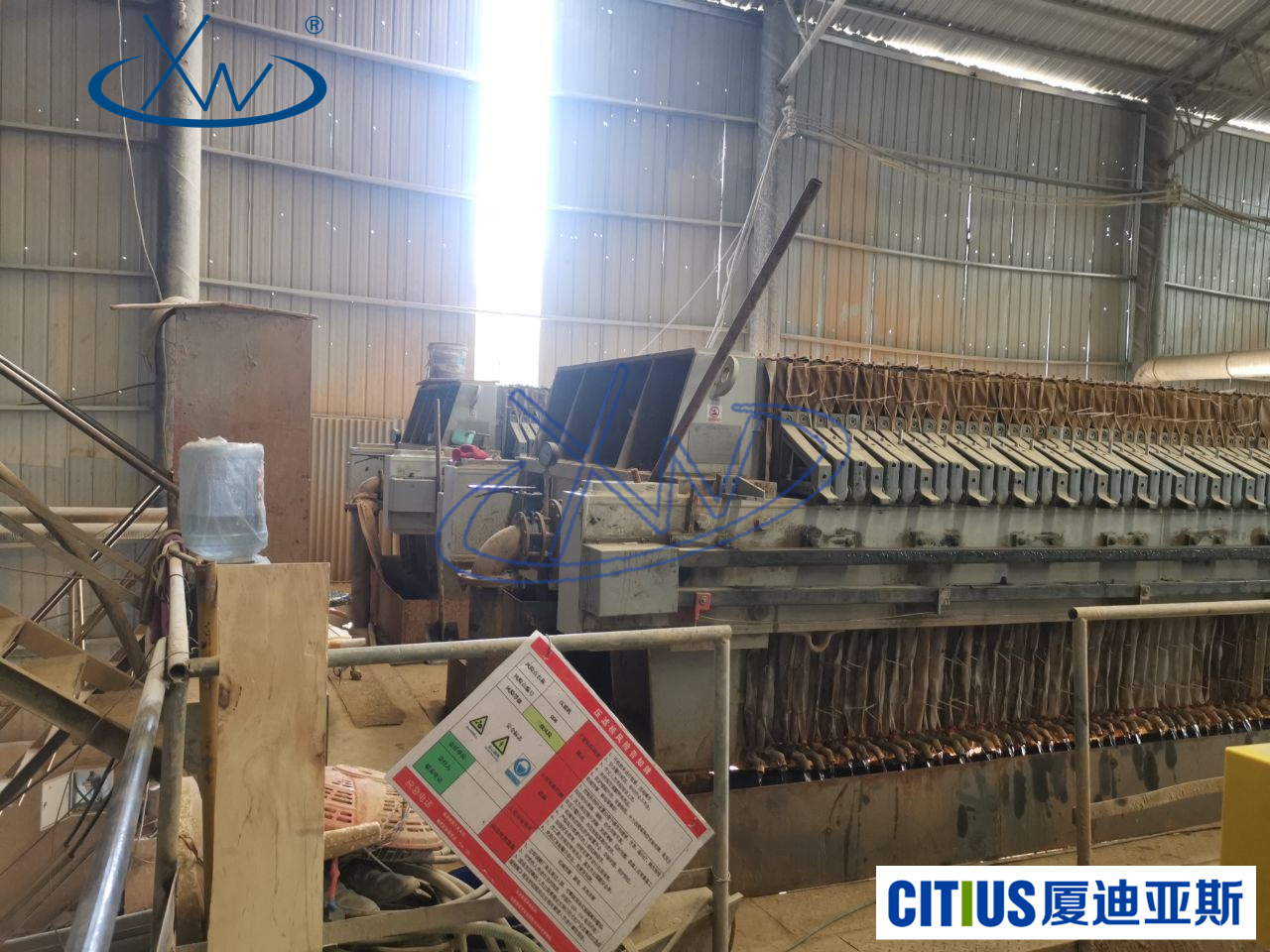

Industrial filter cloth - plate and frame filter press - sand washing plant processing sand washing slurry

Share to

Detailed Description

1. The Importance of Sludge Treatment in Sand Washing Plants

In the process of producing manufactured sand, sand washing plants generate a large amount of washing sludge, which contains fine sand particles, clay, mineral impurities, and moisture. If this sludge is discharged untreated, it will not only pollute the environment but also affect the recycling of water resources. Therefore, it is crucial to adopt efficient solid-liquid separation technology to treat washing sludge.

2. Advantages of Plate and Frame Filter Press in Washing Sludge Treatment

The plate and frame filter press is a common solid-liquid separation device that dehydrates by pressing, expelling moisture from the sludge to form dry mud cakes. Its main advantages include:

- Efficient DehydrationIt can significantly reduce the moisture content of the sludge, decrease the volume of sludge, and facilitate treatment.

- Thorough Solid-Liquid SeparationIt can achieve separation of mud and water, improving the recycling rate of water resources.

- Stable OperationSimple operation, suitable for continuous production.

3. The Role of Industrial Filter Cloth in Plate and Frame Filter Press

Industrial filter cloth is a key factor affecting the performance of the plate and frame filter press. High-quality filter cloth can improve filtration efficiency, enhance the discharge performance of the mud cake, and extend the service life of the equipment. The choice of filter cloth is particularly important for the treatment of washing sludge in sand washing plants, and its main roles include:

- Efficient FiltrationEnsures that solid particles in the sludge are effectively retained, increasing the solid content of the mud cake.

- Wear-Resistant and DurableDue to the presence of sand particles in the washing sludge, the filter cloth needs to have strong wear resistance to extend its service life.

- Anti-Blocking PropertiesHigh-quality filter cloth should have good permeability to reduce clogging and maintain stable filtration efficiency.

- Easy PeelingGood peelability of the mud cake can reduce cleaning time and improve production efficiency.

4. Xiamen Citius(Citius)Technical Advantages of Industrial Filter Cloth

Xiamen Citius Filter Material Technology Co., Ltd. is deeply engaged in the industrial filtration industry, providing high-performance filter cloth products. For the application of plate and frame filter presses in sand washing plants, Citius filter cloth has the following advantages:(Citius)Customized Design(Citius)Provides suitable filter cloth models based on the characteristics of different washing sludges to optimize filtration effects.

- High-Strength Wear-Resistant MaterialsEffectively resist wear from sand particles on the filter cloth, extending the service life of the filter cloth.

- Excellent Dehydration PerformanceEnsures rapid dehydration, reducing the moisture content of the sludge and increasing the dryness of the mud cake.

- Anti-Blocking TreatmentUses special treatment processes to reduce the frequency of filter cloth clogging and improve filtration efficiency.

- 5. ConclusionIn the treatment of sludge in sand washing plants, the combination of plate and frame filter presses with high-performance industrial filter cloth can achieve efficient solid-liquid separation, improve the recycling rate of washing wastewater, and reduce sludge treatment costs. Citius industrial filter cloth, with its excellent filtration performance, provides reliable solutions for the sand washing industry, supporting both environmental protection and efficient production.

Industrial Filter Cloth - Plate and Frame Filter Press - Sand Washing Plant Treatment of Washing Sludge

Plate and Frame Filter Press Filter Cloth Treatment of Washing Sludge(Citius)Filter Press Type: Plate and Frame Filter Press

- Application Industry: Sand Washing

Material Description: Washing Sludge

过滤机类型:板框过滤机

应用行业:洗砂

处理物料描述:洗砂泥浆