High-precision filter cloth for vertical filter press, filtering pharmaceutical tea sodium (caffeine synthesis)

Share to

Detailed Description

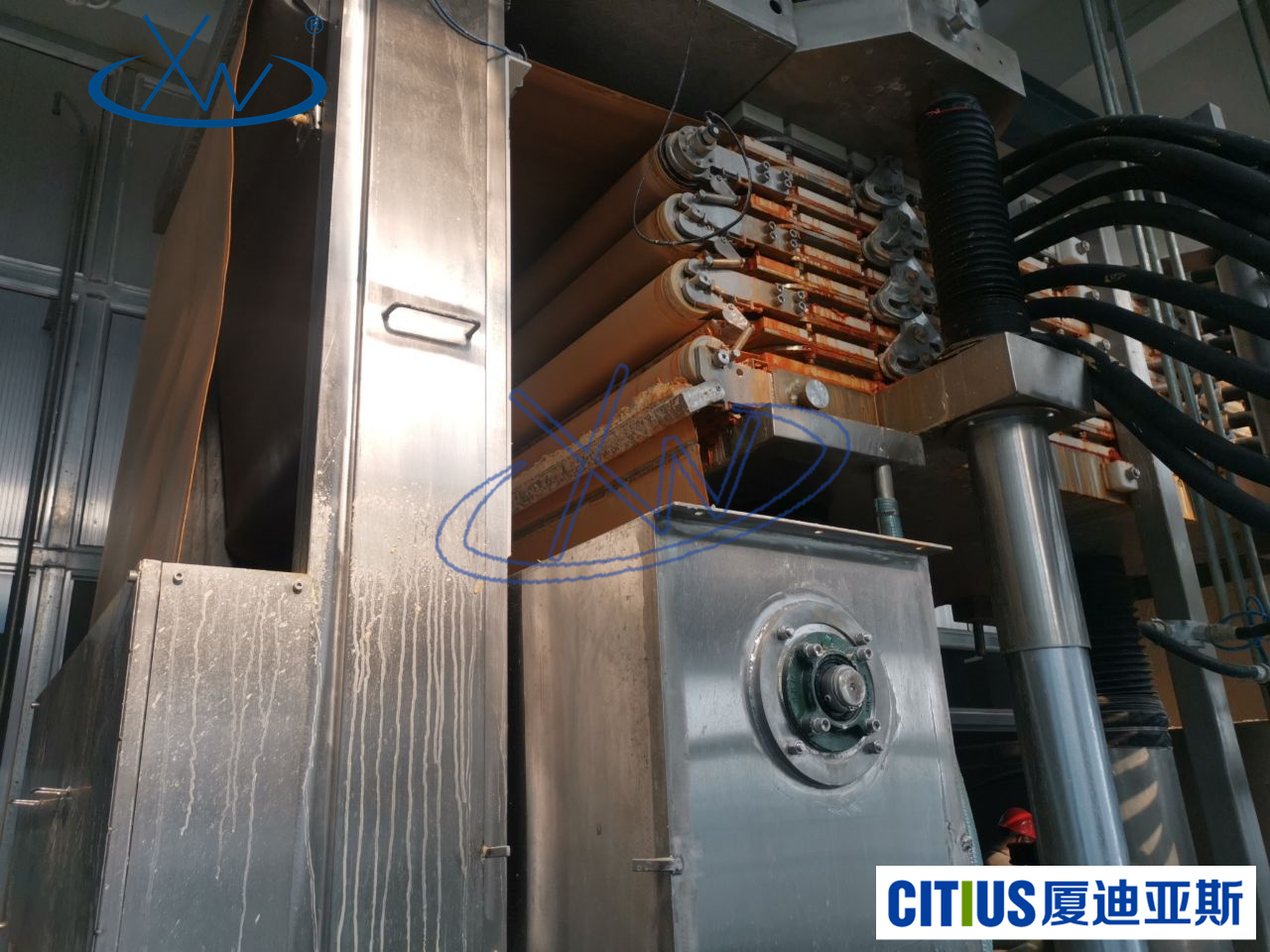

- Vertical filter press filter cloth for pharmaceutical caffeine sodium (caffeine synthesis)

Filter machine type: Vertical filter press

Application industry: Pharmaceutical

Material description: Caffeine Sodium (caffeine synthesis)

Filter cloth model: 2015 ultra-high retention precision

I. Requirements for filtration in the production of pharmaceutical caffeine sodium (caffeine synthesis)

Caffeine Sodium (Caffeine Sodium Benzoate) is a common caffeine derivative widely used in the pharmaceutical and food industries. In its production process, fine solid-liquid separation is one of the key steps to ensure product purity and stability. Due to the involvement of fine particles and solvents in the caffeine synthesis process, the filtration process requires extremely high retention precision while ensuring filtration rate and filter cloth's anti-pollution capability.

II. The role of vertical filter press in caffeine sodium production

The vertical filter press is an efficient solid-liquid separation device suitable for fine chemicals, pharmaceuticals, and other industries, with the following characteristics:

- High-pressure filtration, improving dehydration efficiencyUnder high pressure, the liquid phase permeates the filter cloth, and solid particles form a filter cake, achieving efficient separation.Small footprint, large filtration area

- Suitable for large-scale industrial production, saving factory space.Under high pressure, the liquid phase permeates the filter cloth, and solid particles form a filter cake, achieving efficient separation.High degree of automation, reducing manual operation

- Continuous operation, improving production efficiency.Under high pressure, the liquid phase permeates the filter cloth, and solid particles form a filter cake, achieving efficient separation.III. Xiamen Citius

(Xiamen Citius)Technical advantages of ultra-high retention precision filter clothIn response to the high standard requirements for solid-liquid separation in the caffeine synthesis process, Xiamen Citius

has developed a series of ultra-high retention precision filter cloths, specifically optimized for vertical filter presses, ensuring high purity filtration effects. The main technical features include:Technical advantages of ultra-high retention precision filter clothUltra-high precision retention, ensuring purity

- Using special weaving technology, the pore size is precisely controllable, achieving sub-micron level solid retention, ensuring product purity.

- Suitable for the separation of fine particles and colloidal substances, ensuring that the final product meets pharmacopoeia standards.

- High permeability and low resistance design, improving filtration efficiency

- Suitable for the separation of fine particles and colloidal substances, ensuring that the final product meets pharmacopoeia standards.

- Optimizing fiber arrangement to allow liquid phase to pass quickly while maintaining efficient solid retention.

- Reducing filtration resistance, improving production efficiency, and reducing energy consumption.

- Strong anti-pollution capability, extending service life

- Reducing filtration resistance, improving production efficiency, and reducing energy consumption.

- Using smooth surface treatment to reduce filter cake residue, improve regeneration capability, and lower clogging risk.

- Excellent chemical corrosion resistance, adapting to various chemical media in the caffeine synthesis process.

- Customized solutions to match different production needs

- Excellent chemical corrosion resistance, adapting to various chemical media in the caffeine synthesis process.

- According to specific process requirements of customers, filter cloth solutions with different precision levels and material optimizations can be provided.

- Providing special processing such as reinforced edges and anti-static treatment to adapt to different production conditions.

- IV. Xiamen Citius

- Providing special processing such as reinforced edges and anti-static treatment to adapt to different production conditions.

Application examples of filter cloth in caffeine synthesis filtrationTechnical advantages of ultra-high retention precision filter clothIn the actual applications of multiple caffeine synthesis enterprises, Xiamen Citius

's ultra-high retention precision filter cloth has performed excellently on vertical filter presses, solving the problems of traditional filter cloths being prone to clogging and insufficient filtration precision, significantly improving the purity and yield of the final product, stabilizing equipment operation, extending the filter cloth replacement cycle, and reducing production costs.Technical advantages of ultra-high retention precision filter clothV. Conclusion

The production of pharmaceutical caffeine sodium (caffeine synthesis) has extremely high requirements for filtration precision and stability. Xiamen Citius

, with advanced filtration technology and industry experience, provides efficient and durable ultra-high retention precision filter cloths to help enterprises optimize solid-liquid separation processes and improve product quality. In the future, Xiamen CitiusTechnical advantages of ultra-high retention precision filter clothwill continue to innovate, providing better filtration solutions for the pharmaceutical and fine chemical industries.Technical advantages of ultra-high retention precision filter cloth将持续创新,为医药及精细化工行业提供更优质的过滤解决方案。